10 Of The Most Reliable Jeep Engines Ever Made

When most people think of Jeeps, they picture rugged vehicles built to go just anywhere. Of course, none of that would be possible without a reliable engine under the hood. When it comes to mechanical legacy, few automakers have had a journey quite like Jeep. What started as a World War II military vehicle became a lasting symbol of strength, utility, and reliability. Since 1941, Jeep engines have been built to be stubborn — some to keep moving when conditions got rough, others to stay easy to fix even with basic tools. Through it all — from Willys and AMC to Chrysler and now Stellantis – that purpose has never wavered.

As the brand evolved, so did its engines. Early models ran on small, easy-to-maintain four-cylinders. Later years brought in V8s for more power and inline-sixes that were known for lasting well up to 200,000 miles. Today, these engines feature things like turbochargers, fuel-efficient setups, and plug-in hybrids that blend modern tech with classic Jeep muscle powering everything from Wranglers to Grand Cherokees.

Of course, not every Jeep engine earned its reputation the same way. Some are trusted for long-term durability and high mileage. Others for fuel efficiency, easy repairs, or strong performance in tough conditions. This list highlights the ones that consistently deliver when it matters most — under mechanical stress and in demanding environments.

5.7L HEMI V8

First up is the 5.7L HEMI V8. The engine that reestablished the V8 muscle in Jeep's modern era. Introduced to the Grand Cherokee in 2005, it replaced the aging 5.9L Magnum and brought back the kind of strength and low-end torque Jeep had been missing for years. With around 330 horsepower and 375 lb-ft of torque, it was built for towing, trail duty, and confident daily driving. Most of that torque comes in low — between 2,400 and 5,100 rpm – making it responsive and capable where it counts.

As part of Chrysler's third-gen HEMI family, it kept the classic hemispherical chamber but added refinements — dual spark plugs per cylinder, an updated ignition system, improved fuel delivery, and MDS cylinder deactivation for better efficiency. A cast iron block and aluminum heads kept it strong and balanced.

Owners had a lot to say about the engine's reliability, but like any long-serving workhorse, it had its weak spots. The most talked-about issue was the HEMI tick, usually caused by lifter failures damaging the cam lobes. These problems weren't unique to just Jeep — they showed up across the 5.7L HEMI lineup, from Dodge trucks to Chrysler sedans. Other concerns include worn spark plugs, exhaust manifold bolt failures, and occasional stalls.

Still, if you stick to the service schedule and avoid excessive idling, it'll treat you well. Many owners see 100,000 to over 300,000 miles without major problems.

5.9L Magnum V8 (360 CID)

The 5.9L Magnum V8 only showed up once in Jeep's lineup, but it made that appearance count. Found exclusively in the 1998 Grand Cherokee 5.9 Limited, it was borrowed from Dodge's performance lineup and gave Jeep's luxury SUV serious muscle. Output varied slightly by application, but it typically delivered around 245 horsepower and 345 lb-ft of torque. It was the fastest SUV MotorTrend had tested at the time, hitting 60 mph in just 6.8 seconds. Aside from hood vents, a throatier exhaust, and unique wheels, it looked almost like any other Grand Cherokee.

Mechanically, the 5.9L was built for strength and simplicity. Based on Chrysler's LA engine platform, it featured a cast iron block and old-school pushrod design that was tough, easy to work on, and built for high mileage. Updates like revised heads, multi-point fuel injection, and better sealing helped it run cooler and last longer than its predecessors.

That said, it had a few known issues too – cracked cylinder heads and intake gasket leaks were the most common. For enthusiasts, however, it's a favorite swap engine. Dropping one into a Wrangler TJ is a popular move — it's affordable, relatively easy to install, and gives the Jeep a serious boost in torque and trail power.

2.5L inline-four

The 2.5L inline-four wasn't built for power, but it holds its own when it comes to lasting dependability. Introduced in 1984, this small but sturdy four-cylinder powered models like the Cherokee and Wrangler for nearly two decades, earning an impressive reputation for durability. Most YJ and TJ Wranglers came with either the 2.5L or the more powerful 4.0L inline-six paired with manual or automatic transmissions, but the 2.5L's simplicity helped it outlast them all.

What made the 2.5L inline-four so dependable was its rugged cast iron block, pushrod valvetrain, and shared internals with the 4.0L. Hydraulic lifters, a non-interference design, and fewer moving parts meant fewer things could go wrong, and repairs were usually straightforward when they did. Many owners easily pushed these engines past 200,000 miles with basic upkeep and just a bit of care.

In the 1990s, Jeep added multi-port fuel injection, improving throttle response and refining drivability without compromising reliability. With just 117 horsepower, it could feel underpowered, especially with bigger tires or a lift, but short gearing and strong low-end torque helped it keep up off-road. Fuel economy wasn't far off from the 4.0L either, with most modified Jeeps getting 12 to 14 mpg with either powerplant.

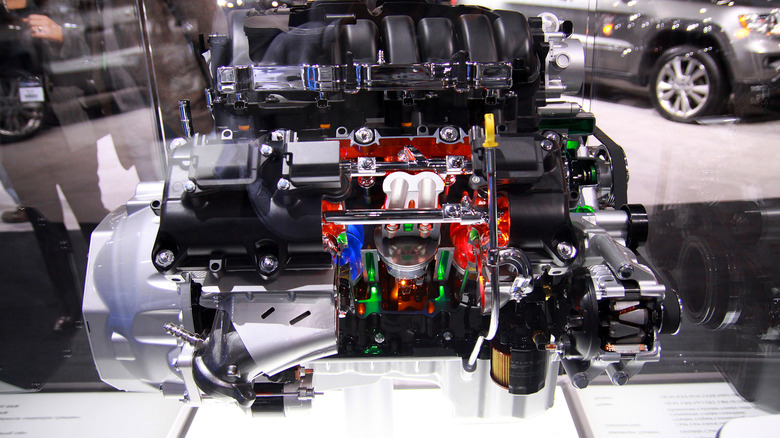

2.0L I4 DOHC Turbo PHEV

The 2.0L I4 DOHC Turbo PHEV powers the Jeep Wrangler 4xe, and it's unlike anything Jeep has done before. First introduced in 2021, this plug-in hybrid combines a turbocharged four-cylinder gas engine with two electric motors and a lithium-ion battery. Together, they produce 375 horsepower and 470 lb-ft of torque, which puts it among the most powerful engines ever introduced to the Wrangler lineup. It offers Hybrid, Electric, and E-Save modes, letting drivers choose how they manage fuel and battery use based on the drive.

Instant torque from the electric motors makes low-speed crawling effortless, while a mechanical four-wheel-drive system and low-range transfer case keep it all Jeep. Components are sealed for water crossings, regenerative braking adds control on descents, and the battery's low placement improves stability off-road. With a Level 2 charger, a full recharge is possible in about two hours, delivering up to 22 miles of electric-only range and an estimated 49 MPGe. The battery also sits low in the chassis, which improves stability on rough terrain.

While it's more complex than a traditional setup, Jeep has refined it since its launch. It has also earned a spot on Wards 10 Best Engines list in 2021 and has already proven itself both capable and dependable.

2.0L Turbocharged inline-four

If the 2.0L Turbocharged inline-four sounds familiar, that's because it's the same gasoline engine found in the Wrangler 4xe plug-in hybrid, minus the EV components. On its own, it puts down 270 horsepower and 290 lb-ft of torque, offering confident performance for both street and trail without the added weight or extra complexity of the hybrid system.

What makes it so capable isn't just the numbers — it's how it delivers them. Peak torque comes in early, giving it a stronger off-the-line pull than the V6 and making it ideal for crawling, towing, and navigating rough terrain. With an aluminum block, dual overhead cams, and direct injection, it's built for both strength and efficiency. Some versions also feature Jeep's eTorque mild-hybrid system, which adds smoother low-speed response and cleaner stop-start operation.

Paired exclusively with Jeep's eight-speed automatic, this turbo four delivers smooth shifts and confident control across varied conditions. While not as rugged as the older six-cylinders, it's the most fuel-efficient gas engine in the Wrangler lineup — up to 23 mpg on the highway with noticeably lower annual fuel costs than its V6 and V8 siblings. This makes the 2.0L a solid choice for buyers who want modern power in a small size.

3.0L EcoDiesel V6

The 3.0L EcoDiesel V6 was a major addition to the Jeep Wrangler lineup in 2020. Built by VM Motori and tuned by Jeep, it brought 260 horsepower, 442 lb-ft of torque, and impressive real-world range. For the first time, Wrangler owners had serious towing strength, trail capability, and highway stamina without constant fuel stops. Some models hit up to 29 mpg on the highway, easily outperforming gas options like the 2.0L turbo and 3.6L Pentastar. Its low-end torque made rock crawling and hauling feel effortless, delivering power right where it mattered most.

Under the hood, it featured a variable geometry turbocharger, dual-loop EGR system, and revised intake ports for better airflow and emissions control. Direct injection, lighter pistons, and reduced internal friction helped it run cooler and more efficiently, earning the EcoDiesel three Wards 10 Best Engines awards during its run.

Still, questions lingered about whether the EcoDiesel was truly any good, and while it had clear strengths, its flaws were hard to ignore. Early models saw EGR cooler and oil leaks, while later ones struggled with oil cooler and cam gear failures. Combined with Jeep's shift toward electrification, it was phased out by 2023. Today, buyers seeking its torque and long-range efficiency will need to turn to used Grand Cherokee, Wrangler, or Gladiator models.

AMC 401 V8

The AMC 401 V8 may not be every driver's favorite engine, but when it comes to reliability, it's hard to beat. Released in the early 1970s by American Motors Corporation, this 6.6-liter V8 became a popular option in full-size models like the Wagoneer, Cherokee Chief, and J-Series pickups. Factory-rated at over 235 horsepower and 330 lb-ft of torque, it delivered the kind of muscle needed for heavy-duty use both on and off the road.

AMC developed the 401 as the third evolution of its high-deck V8 lineage, building on the 390 with more displacement and extra strength before replacing it. It featured a high-nickel cast iron block, forged internals, and thick main bearing webbing strong enough that some builders even drill and tap it for four-bolt mains. Even in stock form, the internals can reach 7,000 rpm in well-built setups. Oiling issues were its main flaws, but these are commonly addressed during rebuilds. In fact, most of its problems today come down to age, not weak design.

With its simplicity, strength, and ease of modification, the 401 remains a go-to for restorers and Jeep builders. Whether you're adding fuel injection or high-compression pistons, it takes upgrades in stride.

3.6L Pentastar V6

The Chrysler 3.6L Pentastar V6 made its Jeep debut in the 2011 Grand Cherokee and joined the Wrangler lineup the following year, replacing the underpowered 3.8L V6. With between 280 and 305 hp and roughly 269 lb-ft of torque — depending on the model — it offered a serious performance upgrade. Built with an aluminum block, cast iron liners, and variable valve timing, the Pentastar was lighter, more compact, and better suited to modern Jeeps like the Wrangler JK and JL.

What every driver needs to understand about the 6.3 Pentastar V6 is that its refinements were key to its lasting success and its reputation. Improved oil flow, better thermal management, and lower internal friction helped it avoid many of the wear issues that plagued older Jeep engines. By 2016, Chrysler had fine-tuned the platform with upgrades that improved combustion and extended service life.

Later versions added a two-stage variable valve lift system, integrated exhaust manifolds, and a cooled EGR loop — all of which improved durability without complicating maintenance. A few engines did face rocker arm failures or sand-casting debris that could affect oil and cooling systems, but those were rare compared to the millions built, and FCA issued updates to address them.

It's no surprise the Pentastar V6 earned a spot on Ward's 10 Best Engines list three years straight. It does not demand exotic upkeep, runs on a simple timing chain, and benefits from wide aftermarket support, which is exactly why so many Jeep owners still trust it today.

Willys Go-Devil

The Willys Go-Devil was the engine that started it all. Designed in the early 1940s, this 134 cubic-inch flathead four-cylinder powered the original Willys MB military Jeeps through some of the toughest conditions of World War II. It came to life after chief engineer Delmar "Barney" Roos reworked Willys' older engine, adding features like a counterbalanced crankshaft, refined valve setup, pressurized oiling, and more. The result was a 60 horsepower engine capable of running up to 100 hours at 4,400 rpm without failure.

Thanks to its L-head layout, low compression, and simple forged internals, the Go-Devil could run on poor fuel and still handle tough tasks like towing supply trailers or moving crew across airstrips. Soldiers could keep it alive with basic tools, and even after long stretches without maintenance, it would still fire up when needed. After the war, the Go-Devil found a new life in early CJ models, where farmers and rural workers valued the same rugged dependability.

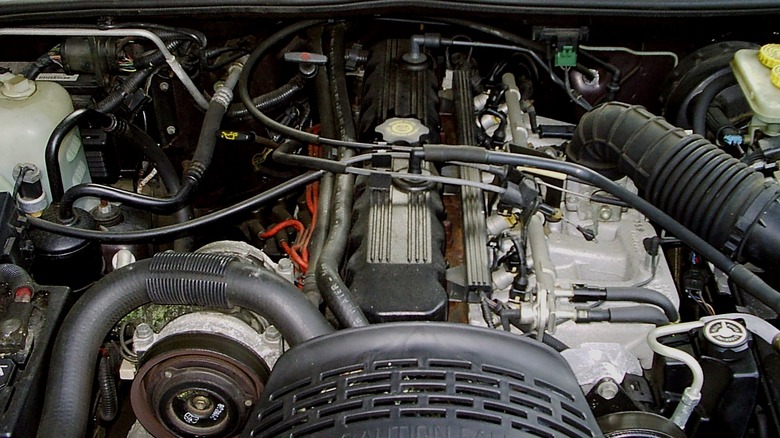

4.0L inline-six

Few engines in Jeep history inspire as much loyalty as the 4.0L inline-six. Launched in 1987, it powered models like the Cherokee XJ, Wagoneer, and Wrangler TJ until 2006. Also known as the AMC 242, it survived Chrysler's takeover of AMC thanks to its legendary toughness. Built with a cast iron block, forged internals, and a non-interference valvetrain, later versions made around 190 horsepower and 225 lb-ft of torque. While there weren't high performance numbers, it built a reputation for running past 200,000, even 500,000 miles, with basic care, making it one of the most reliable gasoline engines in Jeep's history.

What truly made the 4.0L engine so great was its simple, rugged design. Instead of overhead cams, it used hydraulic lifters, rods, and rockers to keep things reliable and easy to maintain. It was also one of the first inline-sixes to feature multi-port fuel injection, boosting drivability without adding complexity. Strong low-end torque, a smooth powerband, and easy DIY repairs made it a favorite both off-road and on. A strong aftermarket kept support alive, and even today, some DIYers have pushed the 4.0L to impressive levels through custom builds.

Of course, no engine is flawless. A few of 4.0L variants had their off years, with issues like cracked exhaust manifolds, oil leaks, and aging sensors. Some even struggled with cylinder head problems. Still, with occasional maintenance or a rebuild, the 4.0L just keeps going.

Methodology

To create this list, we looked at a mix of expert reviews, factory information, and feedback from longtime Jeep owners. We focused on engines that have proven themselves over time, whether through high mileage, strong off-road performance, or low maintenance needs. Some choices earned their spot for simple, rugged designs. Others were picked for combining modern features with real-world reliability.

Sources included Jeep's own materials, automotive publications like MotorTrend and SlashGear, alongside insights from Jeep enthusiast communities.