12 Of The Most Unknown Car Parts And What They're Used For

We may receive a commission on purchases made from links.

Listening to your mechanic as they try to explain what's wrong with your vehicle can feel like listening to someone speak a foreign language when you only know how to order a beer. As a seasoned automotive technician, I've had my fair share of clients ask me to repeat a part name or "speak English." And while you may be sure that your technician is trying their best, often it's the name of the part that needs work that can throw the conversation off the rails. Those mysterious bits and bobs that keep a vehicle running often have labels with strange acronyms or familiar words in unfamiliar contexts.

There are literally thousands of parts in a modern automobile. From tires to antennas, headlights to spoilers, every one has a name and a purpose, and it's just not reasonable to expect everyone to know each and every part by name. However, there are some parts that aren't just oddly-labeled, they're completely unknown. And we're not talking about "blinker fluid," that made up liquid seasoned technicians often make the new guy ask for at the parts store.

We've listed 12 of the most unknown parts and what they're used for below. Some are sensors that keep a vehicle's PCM (whatever that is) working properly and the engine running smoothly; Others are ancillary parts that make sure the main piece of hardware they're related to works without a hitch.

MAF sensor

I've been guilty myself of glossing over this part when explaining to a customer what is making their engine run lean and their tailpipe launch more black smoke than an old-school locomotive. MAF stands for Mass Air Flow, and this sensor creates an optimal air/fuel mixture to maximize the vehicle's efficiency. A dirty or failing MAF sensor can lead to the aforementioned smoke and lean fuel mixture as well as a Check Engine light or rough idle.

Typically sold as a housing that fits in-line with the main hose between the air filter and throttle body — and often completely unknown to car owners and some technicians — the Mass Air Flow Sensor is essentially a pair of wires that measure temperature. The difference between a control temp of 200 degrees Fahrenheit and actual temp is sent to the PCM, and air/fuel ratio is adjusted for best performance.

The two wires are thin and delicate, and given that the MAF sensor is located in line with a vehicle's air filter and throttle body, they can easily become coated with dirt and particulates. If you've found that necessary, or if you're getting code P101 when scanning the vehicle, a quick spray with a mass air flow sensor cleaning spray often takes care of the problem. If it doesn't, MAF sensors are some of the easier parts to replace on this list.

Tow hook cover

Here's a part that most drivers only notice if it falls off, leaving an unsightly square hole in their vehicle's plastic fender with seemingly nothing underneath. A closer look, though, will reveal a purpose for this little cover.

The tow hook cover does what it says on the tin; that is, it covers the point where a tow hook attaches to a vehicle. The tow hook is a connection point for winches or tow truck hooks, although tow hook covers can also block the threaded hole for the connector pin that lives in the spare tire/parts storage area of the vehicle. The cover keeps debris out of that hole, making sure threads are nice and clean when an emergency requires the connection of a tow hook.

My 2016 Jeep Renegade has both bright red tow hooks and an attachment point or two in front, allowing for another Jeep to quickly winch mine out of a sticky situation without damaging my vehicle. While I've only had to use them once, it's very useful to know where the parts are stowed and how to put them together in case of an emergency.

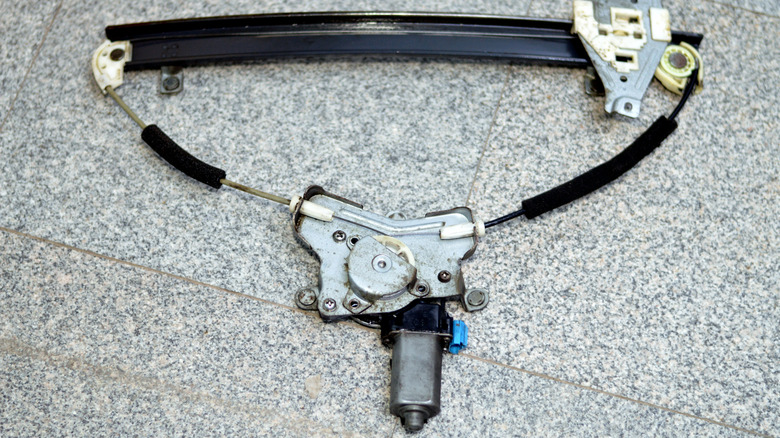

Window regulator assembly

When I was an active technician, one of the jobs I was routinely given because of my skill and speed (and because other mechanics found it tedious) was window regulator assembly replacement. Outside of a shop setting, the replacement of this part that rests inside each door panel can be a pain, since the body clips that secure the door panel in place often break during service, and replacements can be tough to find sight unseen. The part itself consists of a motor, a slot that holds the window glass, connectors, and an aluminum or steel bracket assembly that expands to raise and hold the window in place. That assembly is often bolted or riveted in place, making removal difficult if you don't have the proper tools.

The symptoms for a failing window regulator assembly are usually pretty obvious — either the window won't roll up or down, or the window falls out of view, never to be seen again. The former can mean the motor has failed, the switch has failed, or the bracket assembly has jammed up. The latter often means the bracket that holds the window in place has become loose. Either way, full replacement is often the best and most straightforward replacement. It can be a difficult job, and I recommend leaving this one to the professionals.

Fuel sock

I just got to replace one of these in my 1996 Ford Ranger — no small feat, considering access to the part means removing the entire truck bed. Also called a fuel pump strainer, this seldom-seen filter attaches to the bottom of your fuel pump, which lives inside of the fuel tank of your vehicle. This filter keeps contaminants and debris that gets into the fuel tank out of the pump. A failed or missing filter can quickly result in a bad fuel pump and a stranded motorist.

While it's a very necessary part, the fact is you will very rarely encounter a vehicle that only needs the fuel sock replaced to repair an issue. More often, the fuel sock will fail due to time, allowing more and more contamination into the fuel tank and eventually requiring the replacement of the entire fuel pump. It's important to remember to clean the fuel tank during that job, as all that contamination and buildup can prematurely cause a replacement fuel pump to also fail, once again requiring all the work that is involved in either removing a truck bed or dropping the fuel tank from the bottom of the vehicle.

Zerk fitting

The older salespeople at many shops called an oil change an LOF: Lube, Oil, and Filter. That first part is often ignored by newer and/or lazier techs, but it's an important part of vehicle maintenance, since parts need to be kept lubricated to prevent wear. After all, grease and other viscous fluids are often the only thing preventing rust and metal-on-metal contact between many of a vehicle's parts.

The application of grease used to be a filthy procedure, consisting of just getting a handful of lube and smearing it all over the parts as needed. As time went on, fittings were introduced to allow for simpler and clean lubrication. Today, most parts that require grease have what's known as a zerk fitting, or "grease nipple". It's a tiny screw-in head that accepts a grease gun's fitting to allow grease to get where it needs to be. This was all the result of some innovative thinking by one Oscar Zerk, whose patented Zerk fitting was introduced in 1922 and is still in widespread use to this day.

Wheel cylinder

More experienced technicians may scoff at the inclusion of this part on a list of unknown car parts, but consider this: While nearly anyone is capable of replacing their own disc brake pads, drum brakes are largely mysterious to younger techs because of their lack of exposure to this style of brake system. And a wheel cylinder — the hydraulic part of a drum brake system that applies brake shoes to the inside of a brake drum — isn't exactly a descriptive name for the part's function.

Yes, technically the part itself is a cylinder, but as it's set inside the brake drum, it doesn't come into contact with the wheel at all. It's mounted on the backing plate that holds the screws and plates that a drum brake system consists of, and hydraulic pressure pushes small bars out of either end of the cylinder, applying brake shoe pressure to the inside of the brake drum.

Wheel cylinder failure is almost always the result of a worn or torn seal inside the cylinder. While repair kits are available, a replacement cylinder is often around the same price and guarantees all seals are new. The bigger expense is often replacing the brake shoes, which always seem to want to soak up some of that leaked fluid.

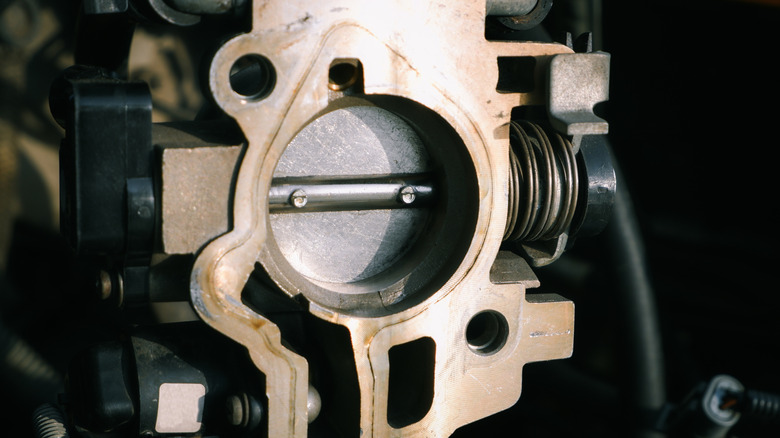

Return spring

The problem with knowing a part's name is that sometimes even that doesn't help locate where that part might go. Take the return spring, the spring that, well, returns the throttle valve to a closed position after the gas pedal is released. If it was called the throttle return spring, or even just a throttle spring, one could figure out what and where this generic-looking metal coil is located without much difficulty. As it is, the vague name of this part makes it one of the more unknown springs in a vehicle that's often full of them.

The return spring comes in two flavors — a coil around the throttle shaft that returns the shaft back to its neutral position when the accelerator is released, and a spring with hooks on either end that connects a bracket to the throttle lever. Both do similar tasks, and both are relatively simple to replace if you're experiencing symptoms like a gas pedal that sticks or doesn't immediately return to its original position, or a high idle.

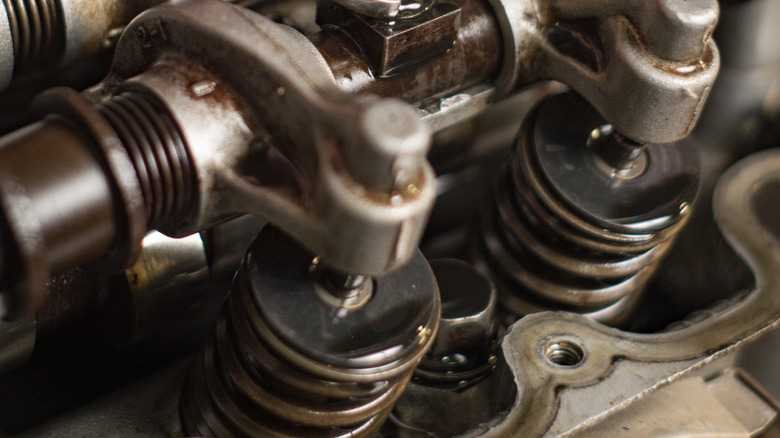

Tappet

Sometimes a part is unknown because it is unique or rare; Other times, it's just a case of mechanics becoming so familiar with an old part name that they transfer that name to something new. One example of that is the tappet, a little cylindrical component that transfers the rotational movement of an engine's camshaft into linear movement. The camshaft rotates in the engine, and valve lifters, AKA tappets, ride the oblong cam lobes along the shaft. That movement is transferred to pushrods and rockers to open and close valves, allowing air into the engine to mix with fuel and create combustion. Tappets got their nickname from the tapping noise that they make as they move up and down.

Technically, the hydraulic lifter has largely replaced the tappet in modern vehicles, but many technicians still refer to the part as a tappet, owing to the fact that if a lifter wears out or clogs it will make that familiar clicking noise we've all heard on the 30-year-old van idling next to us at a red light. While the noise can be annoying, there are a number of solutions for that problem — once you've figured out the source of your issue.

Schrader valve

This is a part most of us know, but few know the name of. The little pin-and-spring combination that threads into every Schrader pneumatic tire valve keeps air in the tire, and allows a special fitting that presses the valve to inject more air as needed. Every cyclist and driver has used one of these at some point, as nearly every bike, car, and truck — anything with tires, really — uses a Schrader valve. Automotive technicians know that the valve's design is also used in many A/C system fittings because of its ability to allow refrigerant to be added or removed from a vehicle's air conditioning system without having to drain the entire system.

Occasionally, a part named after its inventor becomes a proprietary eponym — a name for a category of goods, like Xerox for copiers or Kleenex for tissues. While all Schrader valves are called that regardless of who makes them, it's interesting to note that the Schrader company itself is still in business. And the company didn't rest on its laurels, either; The business now known as Schrader TPMS also pioneered the tire pressure monitoring sensors and systems found in almost all vehicles on the road today.

Sway bar link

A sway bar link is one of those parts that one often doesn't know about until they're either broken, loose, or suggested during strut replacement. The sway bar is a long metal bar that helps prevent side-to-side movement, also known as body roll. The linkages that provide a connection between the sway bar and the vehicle, often at the frame or strut body, tend to rust easily. When those nuts get stuck on, mechanics often require a torch or cutting tool to remove them, resulting in a lot of frustration between the salesperson, the technician, and the customer when the part wasn't sold prior to the work being done.

Ignoring a sway bar link isn't just a problem for technicians, though; A worn ball joint or broken sway bar link will result in noise and excessive body roll. This is a job that an experienced DIY mechanic can accomplish on their own, as long as they have the right tools for the job.

Cabin air filter

One of the most ignored and unknown parts of a vehicle is the humble cabin air filter. Most people know there's a filter under the hood that keeps contaminants from entering the engine. However, there's another important filter in the vehicle that is often overlooked — the cabin filter, which removes pollen and allergens from the interior, or cabin, of the vehicle.

The cabin air filter is often located behind the glove box or in the center console, and is also often a pain in the butt to access, requiring the removal of the glove box, plastic kick panels, or sometimes even electrical connections. And don't get me started on the head rush you get from trying to access the filter on a Nissan Altima — you've basically got to fold yourself into the area in front of the passenger seat and remove and replace the filter by crushing it accordion-style, leaving dirt and debris all over the vehicle for you to clean before the service is complete. But if you don't replace your car's cabin air filter, you get weird smells, annoying noises, and poor AC and heat performances. It's worth the headache to do the job, or worth the cost of labor if you pay for a technician to do it for you.

Strut bearing

Earlier in this article, we had some fun with "blinker fluid," a made-up product used to haze younger technicians in some shops. When I was the new guy at my shop, I was convinced that "strut bearings" were another fictional accessory made up to make me look foolish. Turns out, not only are strut bearings real, they're an essential part of any complete strut rebuild job.

The strut bearing is located between the strut and mounting plate, or sometimes the bearing and mounting plate are one full piece known as a strut bearing plate. Frequently overlooked replacement parts on the top of struts, strut bearings or strut bearing plates are critical for noise reduction. A worn or damaged strut bearing can allow the strut to make a knock or thunk during turns or when driving over bumps, and can also cause steering and wheel alignment issues.

While many shops do a full replacement of the entire strut assembly — usually suggested around 80,000 miles — those that opt to rebuild face frustration if they don't sell these bearings before the job, especially if there's noise after service. Strut bearings and replacement sway bar links may sound like unnecessary upselling of parts, but the small investment in their replacement will save you and your tech a lot of future headaches.