10 Discoveries That Changed The Automotive Industry Forever

Automobiles are one of the wonders of the modern world and have had a profound impact on the course of human development over the last 100+ years. It would be hard to imagine a world without them from our modern point of view, but they only came about as a result of incremental changes resulting from many individuals' ingenuity and tenacity contributing to improvements of the concept. We can certainly look to Karl Benz and the creation of his first motorcar as the official moment that created the auto industry itself, but that vehicle is unrecognizable compared to a new Mercedes-Benz EQS or even an ordinary Volkswagen Jetta.

In any industry history, one can point out milestone moments that helped to define it. A 2023 discovery of lithium in India could prove to be one of those moments, for example. These milestones are often marked by the discoveries and inventions that improve a system or device with ramifications seen and felt on a wide scale and for years after. The automotive industry has been affected by countless instances where a simple idea or observation led to a wider shift in the development of the industry as a whole, although some of these have turned out to either be rather mundane or detrimental. Regardless, it can be interesting to have a look at what defines the overall development and history of the automotive industry. These 10 discoveries are some of those that changed it forever.

Petroleum

It may seem obvious and elementary, but an important consideration is that without oil, we would have no cars. The actual discovery of petroleum is practically impossible to date as evidence of the uses of oil dates back to ancient Iraq in the fertile crescent at the dawn of civilization. Ancient peoples used it for waterproofing and as mortar for buildings and a variety of other uses. Oil continued to be used regionally in similar ways with few novel applications up until the beginning of the industrial revolution.

In the United States, the modern discovery and subsequent development of petroleum began in 1859 in Pennsylvania. A man named Edwin Drake with an obsessive desire to find oil in Pennsylvania poured investors' money and his own toils into his search. It was on August 27th, 1859 that his work paid off in Titusville when he found oil after drilling 69 feet into the ground. The resulting gusher set off a boom for the state that resulted in wildcatters pouring into the area to find their own riches buried below. However, none of this was done in the search for fuel to drive an automobile, but to burn in kerosene lamps as it was far cheaper and easier to produce than the prevailing whale oil used at the time.

Fuel injection

The roots of modern fuel injection can be traced to the discovery by Herbert Akroyd Stuart in 1885 that while kerosene is generally resistant to ignition, its fumes will readily combust. That led to the creation of the hot bulb engine and eventually the diesel engine, which ignites fuel with high compression and requires injection for its operation. The first fuel-injected engine which relied on spark plugs was the French Antionette aero engine, which also happened to be the first-ever V8. Fuel injection was then used widely on aircraft as it performed well at high altitudes and was mostly standardized throughout aviation by the time of World War II.

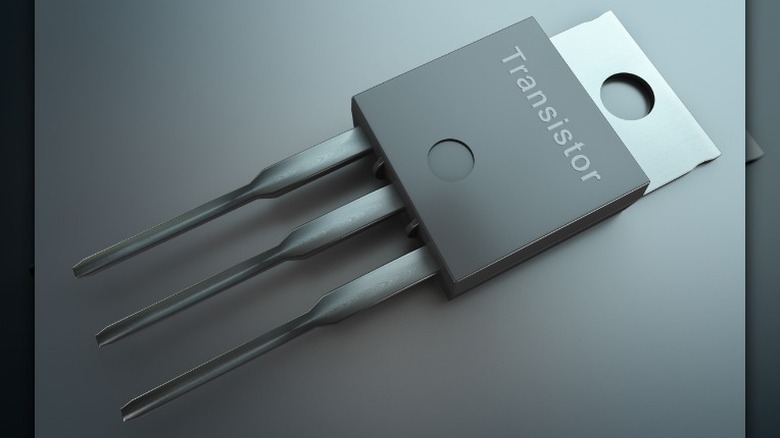

It would take a bit longer for the technology to make it to automobiles. Mercedes-Benz was the first to use it on a production car when it released the 300SL. Stateside, the development of fuel injection in Detroit resulted in the Rochester division of GM adding one of its units to production Corvettes in 1957. This system was purely mechanical, relying on a sophisticated setup of vacuum pods and mechanical servos. At about the same time, Bendix, working with Chrysler, was developing an electronic system that debuted in the 300D in 1958 as well as the DeSoto Adventurer, Plymouth Fury, and Dodge D-500. However, the few that were sold were replaced with carburetors due to massive failures of the system. The controller was built before transistors and integrated circuits were widely used and its complex analog circuitry proved too fragile for the conditions under the hood of an automobile.

All wheel drive

The engineering of drive trains that send power to all four wheels of a vehicle began in the 19th century originally in designs for steam engines. Later, the Spyker 60-HP race car is generally considered the first car to be so equipped. Other than that extremely low production model intended for the race track, four-wheel-drive systems were installed on trucks. As this was also an expensive and complicated addition to a vehicle at the time, the only trucks with such a system were generally highly specialized and used only in those applications where it was necessary, including early military machines.

In modern cars, all-wheel-drive is a common option. This differentiates itself from four-wheel-drive as it cannot be switched off and is intended to give better grip on the street rather than overcome obstacles, mud, and off-road terrain. The first regular production automobile with all-wheel-drive is from boutique British carmaker Jensen. The engineers at Jensen discovered that they could use a drivetrain developed by a company that had been instrumental in the design of the modern tractor, Ferguson Research. Harry Ferguson founded the company that would later become Massey Fergusson, one of the largest tractor manufacturers in the world. The Jensen FF would be the first production all-wheel-drive car featuring a novel use of the drivetrain not to be able to traverse rough ground, but to maintain traction during high-speed driving. Not only would it be a successful but low-volume car, it laid the foundation for the Audi Quattro, allowing the technology to catch on and spread until receiving the widespread adoption of today.

Turbocharging

The first patent was granted for a device that would become the turbocharger in 1905 by the Imperial Patent Office of the German Reich. Swiss engineer Dr. Alfred Büchi received this patent for a "combustion machine consisting of a compressor (turbine compressor), a piston engine, and a turbine in sequential arrangement." One of the first applications of a turbocharger was the Liberty V12 engine used on many airplanes of the WWI era. Subsequently, turbos were only found on airplanes until their application on heavy trucks around the era of WWII.

The first production automobiles to be equipped with a turbo were the Oldsmobile Jetfire in 1962 followed by the Chevrolet Corvair Monza. The technology was new and underdeveloped, lacking modern features such as an intercooler and wastegate. As a result, considerations had to be made to prevent pre-ignition, a common problem with forced induction, by adding a water/methanol injection system to the Jetfire. This required owners to keep a reservoir filled with a special mix, which led to many problems as owners failed to keep up with it — mostly for lack of understanding. As a result, the Jetfirs did not sell well despite having an engine that produced about 40% more power than similar naturally-aspirated models.

The Corvair suffered a similar fate. Its engine was air-cooled, which contributed to problems with overheating. This excessive heat problem was exasperated by the turbo and led to owners constantly having to deal with an overheated car sputtering out. While its problem could have possibly been rectified, Ralph Nader's book "Unsafe at Any Speed," which singled out the Corvair for safety hazards, ensured its demise.

Variable valve timing

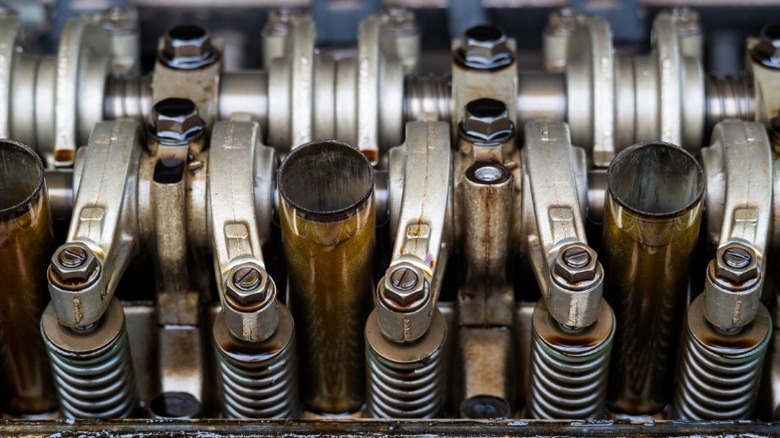

One of the unsung heroes of modern engines is a system that has boosted power and efficiency significantly over the last few decades: variable valve timing (VVT). What this does on a piston engine is alter the timing of the opening of its intake or exhaust valves by using a mechanism to slightly change the rotation of the camshaft. Some engines only change the intake valves while others do both. And while manufacturers have different approaches to changing valve timing, they all work on the same principle.

Experimenting with this technology began in the '80s. Engineers at Honda knew their motorcycle engines with four valves made great power at the top end and two valves were more competent down low. In figuring out how to get the best of both of these, Honda discovered that it could be done by changing the valve timing and creating what would become known as VTEC. Other companies were tinkering with their engines around the same time. Nissan released an electronically controlled system called VCT in its 300ZX in 1987. Faced with increasingly stringent EPA emissions mandates, Alfa Romeo included a mechanical version of it as far back as 1980 in its 2.0-liter Spider, the first production car with VVT. Regardless of how or why it was originally created, VVT systems opened up the possibilities to squeeze increasing power and efficiency from modern engines, and they're largely responsible for the availability of some cars with fuel mileage of nearly 40 mpg as well as other cars with more than 800 horsepower on dealer lots today.

Supercharger

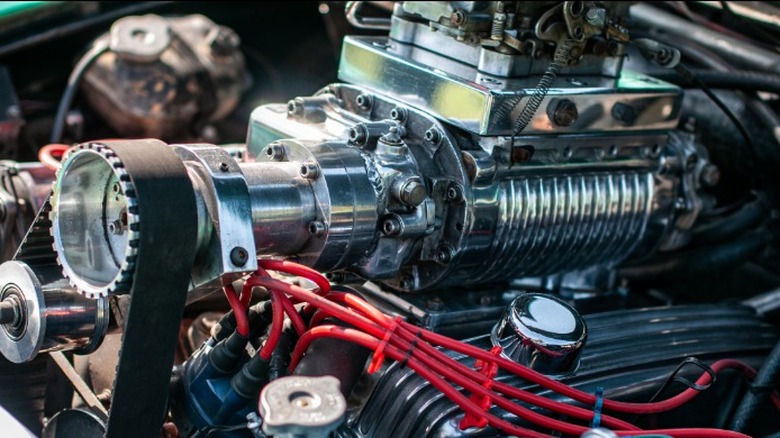

The dynamic of forced induction was first discovered and patented in 1885 by Gottlieb Daimler, whose "grandfather clock" engine used pressure from the underside of a piston rerouted back into the intake to increase the amount of air drawn into the cylinder. It would not take long for others to discover how to increase power output by squeezing more air, which means more oxygen to burn, into an engine. Rudolf Diesel patented a supercharger in 1896 to work with his eponymous compression ignition engine, and in France, other ideas for forcing air into an engine were in development — one from a gentleman named Renault.

One of the types of superchargers we know today was first applied to a gasoline spark ignition engine by Gottlieb Daimler in 1900, who used a Roots-type compressor originally made for blast furnaces around 1849. This kind of supercharger is commonly called a blower and is the large device seen on the top of Top Fuel drag racers. Superchargers, used widespread in aero applications as they help make up for the thin air in high altitudes, and have also been used in a variety of cars since the early days, usually in high-performance applications. Early examples include the Blower Bentley and the Mercedes SSK, and they have been installed on some exciting late-model cars with exciting results. Modern computerized engines and advanced engineering has given us supercharged engines with extreme power output, such as the Dodge Challenger SRT Hellcat with 707 horsepower and the Cadillac CT5-V with 668 horsepower.

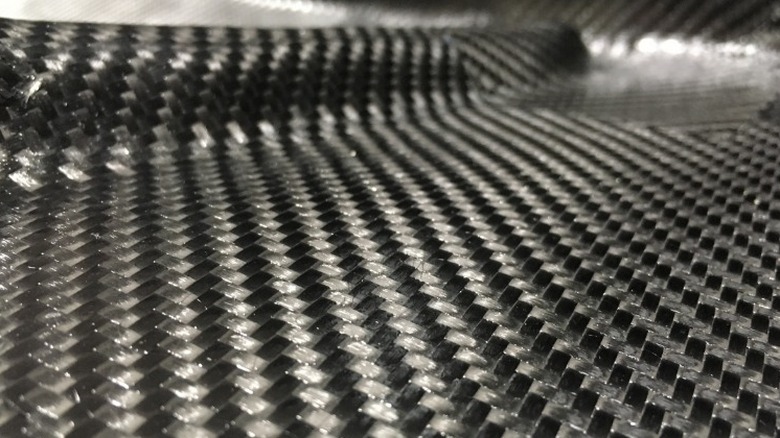

Carbon fiber

In the effort to build increasingly faster cars, engineers have sought ever lighter materials with which to build them. But an issue in achieving lighter weight is doing so without sacrificing strength and rigidity. Some of the earliest methods to do this involved developing new metal alloys, and manufacturers have continued to search for ever lighter materials. And in the second half of the 20th century, the perfect material to accomplish these goals came to be: carbon fiber.

In 1958, Roger Bacon made a chance discovery in which he observed whiskers of perfect graphite after measuring the triple point of graphite. These tiny whiskers, less in diameter than human hair, turned out to be extraordinarily strong yet light. Research and development commenced immediately, with the U.S. Air Force taking a keen interest in it and integrating the material for a wide array of aircraft and weapons manufacturing. Carbon fiber has since become widely available in the consumer market with automakers taking an interest in it in the '80s. A material that is extremely strong but lightweight and flexible is perfect for an automobile. In 1981, British racing firm McLaren was the first to use it in a race car and, in 1992, became the first company to build a street-legal production vehicle, the McLaren F1. It has since been used as the foundation of supercars like Lamborghini and Ferrari, with mass market manufacturers such as VW researching the use of it for regular consumer vehicles in the near future.

Direct current

Electricity is one of the forces of nature that just exists, but we have not always known about it or how to harness it. To develop the vehicles into what we have today, we can thank Thomas Edison for his experiments and inventions in developing direct current electricity.

Direct current (DC) is electricity in which the flow of electrons moves in a continuous direction from positive to negative pole. The energy stored in your car's battery moves through the wiring and switches, returning to the battery through its ground circuit. Without this, the modern car with lights, electric windows, locks, etc. would not be possible.

Much of Thomas Edison's pioneering work was done on DC applications and is the foundation for most of the modern power infrastructure in place today. However, Nikola Tesla at the same time was working with his own ideas in alternating current (AC), and eventually, both types of current were used in various applications throughout the world — including automobiles. The alternator in your car produces AC that is converted to DC to charge the battery. Importantly, the work of both of these gentlemen turned out to be critical components of the world in which the automobile as we know it could exist at all.

The transistor

In the early days of the development of electronics, devices were bulky and delicate due to the components and construction methods available. Circuit boards were filled with diodes and capacitors all soldered together along with a variety of vacuum tubes. The function of all these parts, without going into a lengthy explainer, is to manipulate electricity to perform specific tasks. Research to upgrade electrical devices led to the transistor, which changed everything in the modern world.

Research into making smaller advanced electronics happened in the middle of the 20th century at a fever pitch. At Bell Labs in 1947, a pair of researchers used germanium and gold foil in experiments that would lead to the first transistor. This would be followed by the first silicon transistor at Texas Instruments in 1954 and the development of a metal-oxide-semiconductor transistor (MOSFET) again at Bell Labs in 1960. These developments had a huge impact on the modern world as they allowed electronic devices to be created that were many times smaller and more robust than what had previously existed. It also simplified the manufacture of electronics and led to devices becoming increasingly smaller and more durable that could be used in a wide range of applications, including cars.

While transistor radios appeared in 1956, it was the electronic ignition that increased reliability significantly as the points it replaced required constant adjustment and repairs. Every successive generation of automobile since the introduction of the transistor has been equipped with an increasing amount of electronics. Today, most functions of our cars are completely reliant upon electronics for even basic operation.

The microprocessor

The history of the integrated circuit dates back to 1958 when it was created by Jack Kilby at Texas Instruments. This, along with the transistor, made it possible for computers the size of a room with memory stored in boxes the size of a phone booth to shrink considerably into devices that would eventually become small enough to be portable. However, portable did not necessarily mean small. Computers in the '60s still took up considerable space and were mostly used for advanced mathematical calculations. It was later in 1969 that plans were drawn up to create the first microprocessor that would bring about the personal computer revolution.

These developments would later revolutionize the automobile, beginning with fuel management. In 1968, Volkswagen introduced the first car to come with electronic fuel injection using a Bosch D-Jetronic system with a transistorized computer. The first car to include a microprocessor was the Cadillac Seville in 1978, which featured a Motorola 6802 processor in its digital trip computer. Since then, the role of the microprocessor has increased exponentially such that a modern car uses them in everything from touchscreen infotainment and engine controllers to door locks and power windows. The multitude of systems providing safety, convenience, and performance in a modern car are all functions of many microprocessors. It could easily be argued that the integration of digital electronics has had the single biggest impact on the development of automobiles in the history of the industry.