What Kinds Of Transmissions Do Semi-Trucks Use?

Anyone who's spent any time driving knows that semi-trucks are a fixture on American roads. Vehicles from the most popular semi-truck manufacturers covered just over 500 billion miles in 2022 alone, making trucking companies a cool $940.8 billion in gross revenue in the process. With that much freight volume — and that many trucks — crossing the U.S. daily, it's quite understandable if some of you take these hulking vehicles for granted, never wondering about the technology that drives them forward.

The thing is, though, that semi-trucks aren't just regular passenger vehicles scaled up to epic proportions. Some of the components they use differ from what we get in our regular cars, and one example is the transmissions they use. Granted, they're not necessarily all radically different, but the manual transmissions that semi-truck drivers use will likely be quite alien to most of us used to our conventional manual or automatic transmissions.

Of course, semi-trucks don't just have their unique manual transmissions – most semi-trucks now come with automatic transmissions, while some have automated manual transmissions (AMTs) that combine the benefits of manual transmissions with the convenience of their automatic cousins. Without further ado, let's dive into all the types of manual, automatic, and automated manual transmissions you'll find on a modern semi-truck.

Range transmissions

Let's kick it off old-school and discuss the three types of manual semi-truck transmissions, starting with the range transmission. This type of gearbox usually has its gears in the classic H pattern and allows drivers to move between two gear ranges, doubling the number of gears they can access. For example, 10-speed range transmissions have five physical gear positions, with the high and low ranges doubling the total to 10 gears (plus two reverse gears). A driver will go through the first five gears in the lower range, switch over to the higher range, then move the shifter back to the first gear position, which will now operate as sixth gear.

This dual-range operation is not entirely dissimilar to the high and low settings in four-wheel-drive vehicles. There, engaging the low setting brings in reduction gears that lower the transmission's gearing and allow the off-roader to put down more torque and rock crawl at low speeds. Of course, you're not going to go off-roading in a semi-truck, but the concept of one transmission and two ranges applies to both.

However, where the high and low ranges on an off-roader allow it to cover more terrain than it otherwise would, semi-truck range transmissions are comparatively much less versatile. A range transmission's simple high-low split makes it relatively easy to master, but results in a limited selection of gear ratios. This makes it most suited for flat and simple routes, such as long-haul highway drives without much in the way of gradients or traffic.

Splitter transmissions

Splitter transmissions are conceptually similar to range transmissions in that each gear position on the H-pattern shifter offers more than one speed. However, the main difference is that the driver doesn't shift between two ranges in general. Instead, each gear gets split — thus the name — into high and low ratios, thereby essentially offering two gears for each position on the shifter.

So instead of going through all four or five low-range gears before shifting into high range, a splitter transmission sees the driver moving through both ranges of each gear as they move up the gearbox. The gears go first gear low split, first gear high split, second gear low split, second gear high split, and so on, until the driver reaches top gear.

A splitter transmission gives drivers quick access to more gearing options than a range transmission, making them much more flexible and adaptable to various situations. Having the granular control of a splitter transmission makes semi-trucks easier to drive in start-stop city traffic, for example. These transmissions are also great for regional hauling, as the longer routes – compared to local trucking — mean that truckers may have to deal with more varied terrain than a simple range transmission can handle.

Range-splitter transmissions

Range-splitter transmissions, as the name suggests, combine the previous two transmissions into one. These transmissions have the high and low ranges of a range transmission, but also offer low and high splits for each gear, like in a splitter transmission. This opens up even more control over a semi-truck's speed and pulling power, essentially offering a semi-truck driver the best of both worlds.

However, the relationship between the ranges and gear splits varies, depending on the transmission. For example, 13-speed Eaton transmissions only offer the split function in the transmission's high range, while the company's 15-speed transmissions only let drivers split gears when they're in the low range. Eighteen-speed Eaton transmissions, on the other hand, enable gear splitting in both low and high ranges, giving drivers the most options when hauling heavy loads.

Regardless of the setup, the combination of two ranges and gear splitting makes range-splitter transmissions the favored choice for semi-trucks working in rougher environments and varied terrain. Semi-trucks involved in construction, for example, which may have to haul all sorts of loads over unpaved paths, can benefit from the increased control offered by range-splitter transmissions. The increased choice of gears also has the knock-on effect of potentially improving a semi-truck's average mpg, which is good for a company's bottom line — and the environment.

Planetary automatic transmissions

Now that we're done with the three types of manual transmission in semi-trucks, let's move on to the two types of automatic transmission regularly seen in these freight vehicles. First up is the planetary automatic transmission, which uses a torque converter and planetary gears to offer multiple gear ratios without needing any input from the driver.

If those terms seem familiar, that's because they should be — this type of automatic transmission works identically to the sort of automatic transmission that was popular on passenger cars up until companies like Honda started using CVT transmissions en masse in the 2010s. Essentially, this type of automatic transmission works by driving a torque converter, which uses engine power to build up pressure in the automatic transmission fluid. This, in turn, moves the vehicle — in this case, a semi-truck — forward.

Once the semi is in motion, the planetary gears come into play. These gears, which consist of a sun gear, planet gears (and a carrier), and the ring gear, move and engage each other in various relationships. For example, one gear ratio may use the sun gear as the input gear and the planet gear carrier as the output, while another moves the input to the planet gear carrier and has the ring gear as the output gear. These various permutations create the multiple gears available in an automatic transmission.

The main benefit of a planetary automatic in a semi-truck is — as you might expect – ease of use. They also make for a smooth drive and work in most situations and terrains. Automatics can also be more fuel-efficient than manual transmissions, albeit at the cost of potentially more complex repairs if things go wrong.

Dual-clutch transmissions

The second type of automatic transmission present in semi-trucks should also be familiar to most of you, especially those interested in the slightly more premium end of the automotive industry. Yes, it's the turn of the dual-clutch transmission (DCT), which offers many of the same benefits in semi-trucks as they do in passenger vehicles.

Dual-clutch transmissions are relative newcomers to the commercial truck space, with the Mitsubishi Fuso Canter trucks from 2012 being one of the first instances of a DCT being used for transporting cargo. Of course, those Mitsubishi trucks were small fry — relatively speaking, at least — and it wasn't until 2014 that DCTs started infiltrating the world of the semi-truck, thanks to Volvo's I-Shift Dual Clutch transmission. Dual-clutch transmissions grew in popularity after that, and modern semi-trucks like Volvo's FH500 continue to fly the DCT flag for the benefits of this particular transmission technology.

Semi-truck DCTs operate on identical principles to those you'd find in a DCT-equipped car. They have two clutches and input shafts — one set controls the odd gears while the other handles the even gears. Having both sets of gears going at the same time allows for quick computer-controlled shifts that prevent any significant loss of power between gears, which is very handy for semi-trucks that need to accelerate quickly or are covering particularly hilly terrain. DCTs are also more efficient than planetary automatic transmissions, another boon in the quest to reduce emissions from heavy-duty vehicles.

Automated manual transmissions

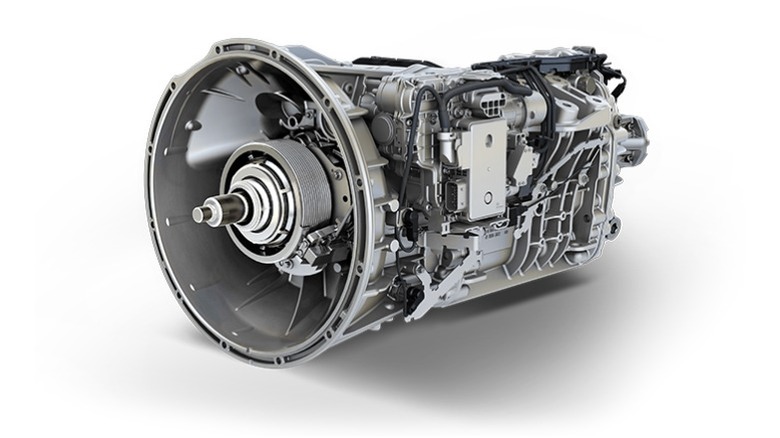

Now that we've covered manual and automatic transmissions in semi-trucks, we can end our list with a hybrid of the two, the automated manual transmission (or AMT). The AMT is a halfway point between a standard manual transmission and an automatic transmission — instead of using a torque converter and planetary gears, an AMT is a conventional manual gearbox with electromechanical or electro-hydraulic systems that activate the clutch automatically, without requiring the driver to depress the clutch pedal.

This may seem like fancy tech, but it's not as cutting-edge as it may seem. An early example was featured in the 1942 Hudson, and it's also present in affordable global-market vehicles like the Maruti Suzuki S-Presso. That said, you generally don't see AMTs in the U.S. because Americans have grown used to the smooth shifting of torque converter-based automatics. The lack of a torque converter also means that AMTs don't have the idle creep of conventional automatics, which can be useful in certain situations.

The AMT's lack of stateside popularity hasn't stopped transmission manufacturers from building some fancy AMTs, however. Detroit, for example, has an automated manual transmission in its product lineup that uses a computer-controlled air system to engage the clutch and shift gears. Not only does this make an AMT-equipped semi-truck easier to drive than a conventional manual, it also provides quality-of-life features such as automatic coasting to improve fuel economy, gear skipping, and even self-adjusting cruise control.