3 Different Automatic Transmission Types Explained

Throughout the 1900s, cars with manual transmissions slowly gave way to those with the ability to shift between gears automatically. Early automatic transmissions with names like Hydra-Matic, Dynaflow, ZF, and Hondamatic delivered simplistic driving, but heavy planetary gear systems and torque converters sacrificed fuel efficiency. The introduction of Corporate Average Fuel Economy, or CAFE, standards following the fuel crises of 1973 forced automakers to increase fuel efficiency across vehicle lineups.

Early automatic transmissions typically had three or four forward gears, some with a 1:1 final gear drive ratio and others with final gear overdrive. As consumers and governments raised the bar for fuel efficiency, automakers developed automatic transmissions with more gears. Additional gears with closer ratios between them allowed smaller gasoline engines to remain within their optimum rpm range for increased fuel efficiency.

Modern automatic transmissions offer up to ten speeds or gears to quickly respond to engine loads and speed, but not every automatic transmission is the same. Continuously variable transmissions offer a single speed that infinitely adjusts its gear ratio as required. Automated manual transmissions use electronics to automate gear shifting, eliminating the need for pressing a clutch pedal with your foot or manually shifting between forward gears. Let's dig a little deeper into the different kinds of automatic transmissions and what sets them apart from one another.

Torque converter automatic transmissions (AT)

Traditional automatic transmissions use a torque converter attached to the flywheel at the rear of the engine's crankshaft to create a fluid coupling between the engine and transmission. The three main parts inside the torque converter are the impeller, turbine, and stator, which work together to pressurize automatic transmission fluid. Automatic transmissions use this pressurized fluid to operate a series of internal gears, pistons, and bands via an internal hydraulic system.

At higher rpm, the torque converter transfers nearly all of the engine torque to the transmission and through the drive line. However, the torque converter's fluid coupling between the engine and transmission transmits very little torque at low rpm. This fluid coupling allows the car to stop without stalling the engine — a similar function to the clutch assembly in a manual transmission driveline.

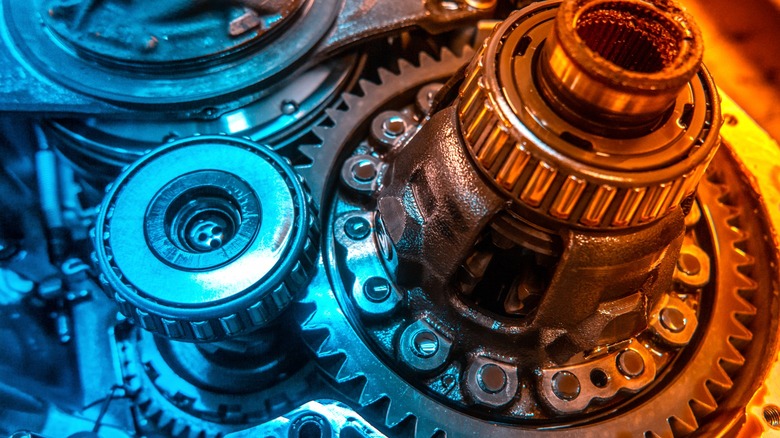

Inside the automatic transmission, a series of bands and clutches, operated by the hydraulic system, work together to shift the compound planetary gear set. A single planetary gear set consists of a central sun gear surrounded by a ring gear and smaller planet gears rotating between them on a planet gear carrier. Compound planetary gear sets multiply the basic setup by two or more to achieve multiple drive gear ratios.

Continuously variable automatic transmissions (CVT)

Considering its recently rising popularity amongst automakers, the continuously variable automatic transmission (CVT) might seem like new technology to some. However, Leonardo da Vinci had already drawn plans for a rudimentary version of it over 500 years ago. Of course, modern CVT variations are far more advanced than da Vinci's designs.

The most common CVT uses a variable pulley system. The simplified version features three parts: an input pulley powered by the car's engine, an output pulley attached to the driveline, and a belt that stretches between them. The lightweight variable pulleys essentially replace the need for heavy compound planetary gear sets.

Starting with small input and large output pulleys allows the optimal engine and input pulley rpm to turn the driven or output pulley much slower. While pressing the accelerator pedal causes higher engine rpm, it also increases the input, or drive, pulley diameter and decreases the driven pulley diameter to create an infinite range of gear ratios for optimized engine performance.

Automated manual transmissions (AMT)

An automated manual transmission (AMT) contains simplistic gear sets like a manual transmission. Then, it goes hi-tech and uses the vehicle's onboard computers to control servo-actuated clutch and shifter operation.

Compared to other types of automatic transmissions, especially CVTs, some AMTs exhibit shift lag, which is slower than desired when shifting from one gear to the next. Some performance-oriented brands, such as Porsche, developed proprietary dual-clutch automated manual transmission (DCT) technology to combat shift lag and increase performance. Thanks to its rugged simplicity, quick shifting, efficient operation, and low production costs, DCT technology found its way into mainstream cars at multiple price points.

Two separate gear trains exist inside the DCT, one with odd gears and the other with even. Each train has a clutch, and while an odd gear (first gear, for example) is engaged, the second gear (even) is already selected with its clutch disengaged, waiting for the proper speed for engagement. The odd-side clutch disengages as the even-side gear train engages, resulting in nearly instantaneous shifts.