5 Ways You Should Never Use Dielectric Grease

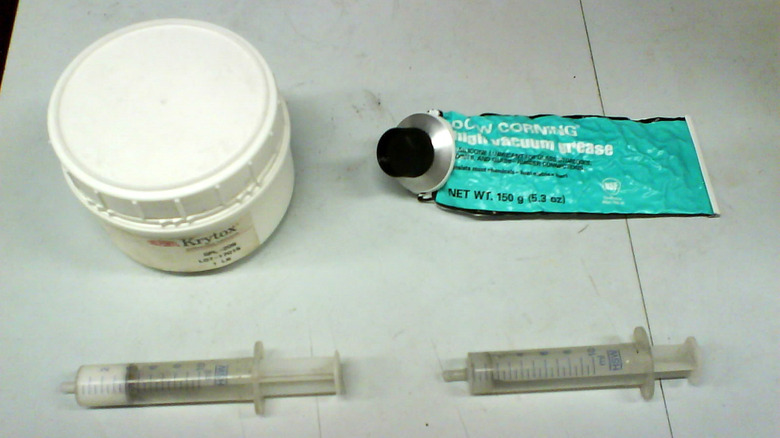

Dielectric grease is supremely helpful, but often misunderstood. The compound has all sorts of applications, including on automobiles, in electrical work, and basically anywhere else where electricity flows. At its core, it's a silicone-based non-conductive compound that seals off electrical components from the outside world. That may seem simple enough, but the rules around dielectric grease are often misinterpreted, and that has led to decades of assertions and use that, while may not always harmful, are also not always correct.

Even today, Reddit is chock full of people asking about dielectric grease, its applications, and its use. If you read the comment sections for any of those posts, you'll often have people with conflicting information and opinions, which makes learning about this super useful grease even more difficult, which is interesting to think about considering your car probably has a pound of the stuff strewn about its various components. For the most part, dielectric grease is simply there to keep water and dirt away from electrical connections, but it's a little more complicated than that.

So, if you want some extra information about dielectric grease and how to use, here is a list of things that you should avoid doing that will get you the maximum result from your dielectric grease. It's not easy to mess up with dielectric grease, which is why these rumors have been around for so long, but it helps to avoid doing these things anyway.

Don't impede metal-to-metal contact

Dielectric grease is made to go around electrical components, not between them. This is a very important distinction as it can cause problems if not heeded. In general, electrical connections usually rely on solid metal-on-metal contact to achieve the least resistance possible for the electricity to flow from one component to the next. Dielectric grease can get in the way of that, causing either a weak connection that'll malfunction over time or other potential problems.

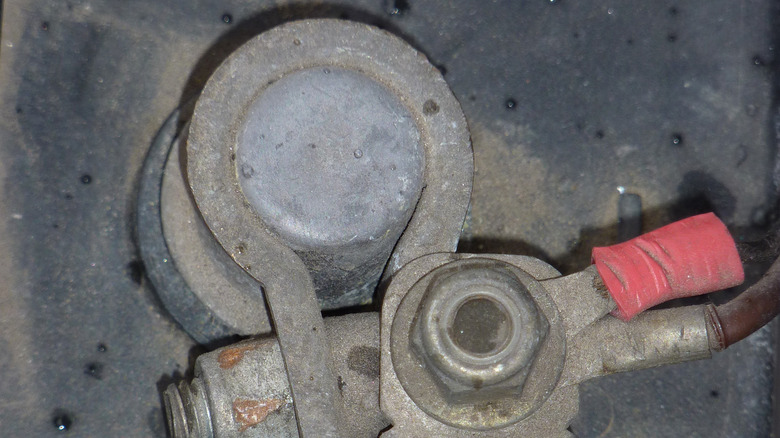

There may be people reading this right now scoffing at what I just wrote, mostly because there is a reason this particular rule has been broken for so long. Many connections, such as the humble car battery terminal, are usually so tight that any dielectric grease put in there gets pushed out, thus preventing any problems. If done correctly, there isn't any dielectric grease to impede the metal-on-metal contact.

However, not every connection is that tight. For looser situations, it's important to make the connection first and then put dielectric grease around it. Incorrectly letting a layer of dielectric grease rest between contact points will reduce the connection strength and cause problems down the line, assuming they don't arise immediately. The old ways still work sometimes, but I wouldn't rely on that knowledge all the time.

The di in dielectric means anti-electric

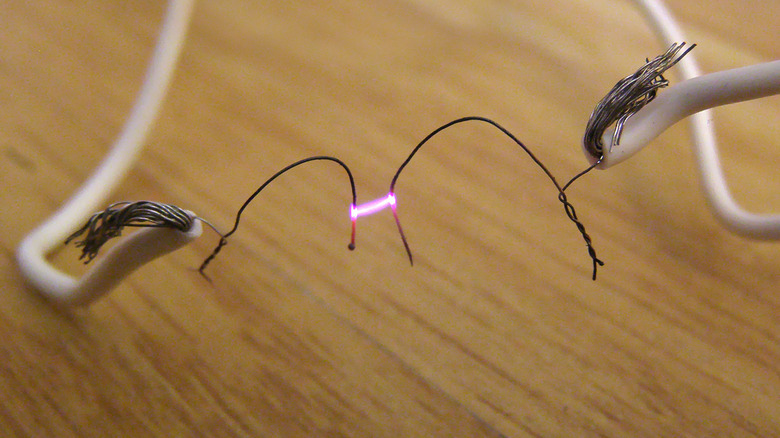

The reason you don't want dielectric grease between your contact points is because the paste is designed to not conduct electricity, and thus, it shouldn't be anywhere where electricity needs to pass through. This point is often argued in online forums (mostly pedantically), but non-conductive materials, also called insulators, dramatically impede or completely prevent the flow of electricity through them. Dielectric grease is non-conductive, so no matter how it's phrased, electricity simply does not go through it very well.

To put it bluntly, dielectric grease doesn't improve conductivity and will, in fact, make it more difficult for electricity to pass through if used between two electrical connections where the connections don't force the grease out. Once again, the best method is to make the connections you need to make and then apply dielectric grease over top of the whole connection. This will achieve what dielectric grease is meant to achieve: Protecting the connection from dirt, water, and other elements, while also not impeding the flow of electricity.

Now, there are exceptions. Some types of underground and waterproof wire nuts use dielectric grease at the entrance, which means you have to push the wires through to get the wire nut to bite. However, these connectors are designed to be tight enough to force the grease out, or the grease is applied after the connection is made anyway.

The incorrect side of the spark plug

A common use for dielectric grease is on spark plugs. In fact, many places will upsell you the stuff when you buy spark plugs. This has happened to me twice, once when I was buying spark plugs for my riding mower and once when my brother was buying spark plugs for his car. In general, it's not a bad idea to use some dielectric grease on spark plugs, but you have to know the correct side on which to do it.

You shouldn't use dielectric grease on the threaded side of the spark plug. As a lubricant, it can mess up your torque values and cause you to overtighten the spark plug, which can break it. Modern spark plugs also don't need lubricant, as they come with a coating that serves that purpose. The other reason is because dielectric grease is non-conductive, and if it gets on the tip of the spark plug, it can cause a bad connection, resulting in engine misfires and other potential troubles.

The correct way to do it is to apply a small layer on the boot of the connection, far away from where the electricity flows, and maybe some on the wired side after connecting it. This will help seal the connection and wiring and keep any errant water from getting in and causing electrical problems later on. Just keep it away from the threads and the tip, and you should be good to go.

Don't use too much or too little

Dielectric grease, as with most lubricants, does its best work in small doses. You obviously want to use enough to lubricate or protect a connection, but once you have that accomplished, excessive amounts don't really do much other than waste product. Over the long-term, should you ever need to mess with that connection again, you'll have to clean up all that grease, which can be a massive pain. Plus, that much extra grease will attract dust and other grime, making the cleanup process that much worse.

Much like WD-40 and other lubricants, you really only need enough to cover the area you're working with. A little goes a long way, and while you don't want to use too small of an amount, it's equally detrimental to use too much. In addition to a nasty cleanup further down the road, too much grease can prevent heat from escaping, causing overheating that may damage components or cause other problems like a potential fire.

Not using enough has a predictable effect. A coating that is too light will not protect components, allowing water and dirt to reach the connections and causes corrosion and other damage. It's one of the many reasons car battery terminals corrode, so it's a good idea to clean things up and seal things up without using too much.

Don't put it anywhere you wouldn't use silicone lubricant

All dielectric grease is made out of silicone — that's part of the reason it resists electricity. Generally speaking, silicone lubricant is excellent at most things, including plastic on plastic, metal on metal, and more. It's usually not a big deal if you drop some on something like wood, either. However, like all things, there are some instances where you don't want to use a silicone lubricant, and that applies to dielectric grease as well.

There are two main areas where you don't want to use silicone lubricant of any kind. The first is around painted walls. Silicone lubricants can seep into the paint and cause damage, usually resulting in fisheye defects. This can happen on car paint as well, which is the biggest concern for dielectric grease. The other time you shouldn't use silicone lubricants is around silicone rubber. The two interact in a strange way, causing the rubber to weaken over time, and eventually fail. This isn't terribly common in automotive or electrical uses, but it's something to keep in mind anyway.

Other than that, make sure to read the label on the back of your dielectric grease for usage instructions and make sure to follow all package directions. It can prevent failure or other issues that may arise from misuse.