11 Woodworking Power Tools That Are Essential For Advancing Your Skills

We may receive a commission on purchases made from links.

Woodworking offers numerous benefits. Just the creative process gives back in a meaningful way, and that's before you consider the fruits of your labor. Woodworking doesn't have to be supremely expensive or time-consuming. There are lots of small woodworking projects that beginners can tackle with little to no experience, and you can find plenty of tools listed for under $100 to get yourself going.

If you're serious about woodworking, there will come a time when you need to bolster your capabilities and production schedules. The more you learn in this field, the more you'll want to create. With that expanded hunger for building comes a desire to bring in additional equipment that can get the job done faster, more effectively, or even gear that just makes your life easier.

I have dabbled in woodworking over the past few years, tackling various projects here and there, such as building a workbench and constructing display boxes. Some of these tools are in my collection, while others remain an aspirational addition to my own workspace (such as a jointer). All of these power tools serve a purpose in the woodworking shop, and each one can amplify the capabilities available to you as you continue to gain skill and confidence.

Router (and ideally a router table setup)

The wood router is a critical power tool for all kinds of users, not just those engaged in woodwork. Routers provide a critical finishing capability that isn't available from other power tools. Trim routers are essential for rounding off edges and applying finishing detail work to the corners of your work pieces. Others, like a plunge router, feature a mobile base that allows you to set your tool where you want it and then plunge the blade into the wood's surface. This type of router allows you to cut grooves and channels into the face of a board you're working with.

Another option is a router table. This is a dedicated tool station with a built-in cutting solution, designed for you to bring the workpiece to the tool, rather than clamping the workpiece in place and bringing the tool to it. Your router will certainly perform a huge range of functions in the workshop, and so having one or more of these tools on hand is critical. Makita and Milwaukee compact routers are both great for buyers seeking high-performance standards and solid versatility.

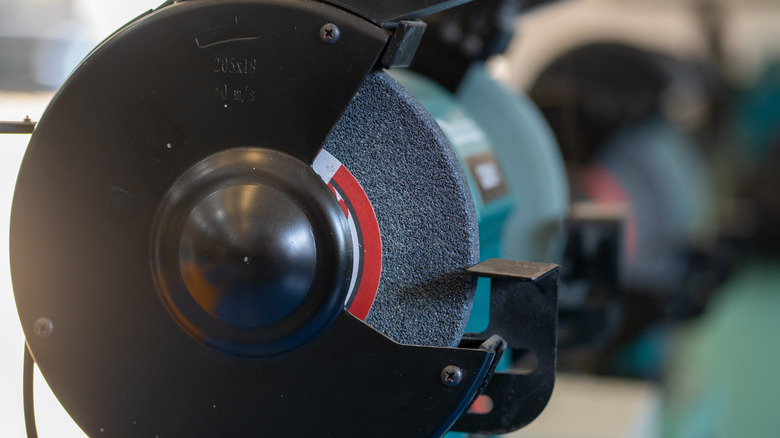

Bench grinder

A bench grinder is another workshop essential that many early-career woodworkers won't typically have access to. In a small space, the bench grinder might feel redundant. It's a tool that must be set up on your workbench and left there permanently. This dedicated space may not be available early on in your woodworking adventure.

With that being said, as soon as you can introduce this solution, you should prioritize it. The bench grinder won't primarily serve as a work manipulation tool. However, these solutions tend to include numerous attachments and augmentations. You can use a bench grinder as a polishing wheel or for sanding duties, in addition to its primary function. The most prominent use case revolves around honing blades. Bench grinders allow you to sharpen chisels and knives, some saw blades, and other critical workshop gear. This will keep your cutting implements working at their maximum capacity without forcing you to spend hours repairing the bladed edges of your equipment.

Additionally, a bench grinder can aid in shaping tasks or part augmentation. Perhaps you need to shave down just a small amount of material off the end of a screw; a bench grinder is the perfect piece of equipment for this task. A great starting point might be Metabo's 6-inch grinder, but for those with a little more budget to play with, there's not much that compares to a Jet (an 8-inch model is available at Amazon).

Table saw

The table saw is, of course, found on this list. There's no avoiding the vast functionality that table saws bring to the workshop. A table saw expands tremendously on the cutting power you have at your disposal. Most woodworkers and renovators will invest in a miter saw early on in their journey. The miter saw is an absolutely invaluable addition to your tool collection. A table saw can perform all the same cuts as a miter saw — although sometimes with a far more convoluted approach — while adding additional functionality into the mix beyond standard mitered cuts.

One of the most important coverage areas that a table saw offers is in ripping sheets and boards lengthwise. Unlike a miter saw, your table saw requires you to move your workpiece to the blade; it remains stationary as you work through a cut, allowing you to deploy a series of pushing tools and perhaps even jigs that lock in a board's trajectory across the blade. Add to the mix the ability to raise and lower the blade for large or small cuts and adjust its angle, and you have a tool that can perform just about any cutting task you might require along a straight line. The SawStop table saw is the pre-eminent solution for woodworking in this category, but it costs a pretty penny. A DeWalt portable table saw or the Skil jobsite saw (with an included folding stand) are both cost-effective choices that deliver great performance.

Band saw

The table saw is a veritable weapon in the woodworker's arsenal. Cutting boards down to size for your next project is a task that features in just about every new build — and the table saw is a critical ally in these efforts. Yet, there are some things that even this tool can't accomplish. Ripping a board across its short length is the table saw's bread and butter, but if you need to flip the board on its side in order to cut across the long dimension, you'll almost certainly run into some problems.

Engaging in a book-matching cut, for instance, requires a different tool. Specifically, you'll need a bandsaw to rip boards this way. A bandsaw is admittedly a much larger piece of equipment than most other tools you'll bring into the mix early on in your woodworking career. In a small shop, it might feel a bit overbearing. However, the addition is absolutely worth it, and not just for one-off cuts to support tasks like book matches.

Importantly, bandsaws are available in large formats (such as the Laguna 14) and a much smaller design (like the Wen 9-inch benchtop model). Therefore, you can opt for a large tool with a very tall throat to support wide cuts, or a tabletop variant to tackle light-duty tasks while incorporating some of the other functionality inherent to this tool.

Electric hand planer

The next tool on this list is one that many woodworkers might be familiar with. Even so, familiarity doesn't always translate into ownership without good reason. Most woodworkers will own at least one hand plane. The plane is a cutting tool used to flatten and smooth out imperfections in boards. With a few clamping solutions and a hand plane in your grasp, it's entirely possible to flatten and square up a board without power tools. However, using the hand tool in this manner will take quite some time. For most modern woodworkers, the hand plane is a finishing solution and not a primary lumber processing system. There are certain times, though, when attacking a board by hand rather than with your powered cutting solutions is the best approach.

A solid middle ground option is the electric hand planer. This delivers faster cutting power without ramping up all the way into the realm of true powered sawing. An electric hand plane should perhaps be contained within a similar conversation around efficiency as an electric sander. Rather than ripping through boards indiscriminately, an electric planer enhances your capability while providing what amounts to roughly the same interaction with the board you are working on. This can save you a lot of time, allowing you to focus on other tasks. Bosch offers a high-quality corded option (available on Amazon), and the DeWalt 20V Max cordless planer can also be a great addition.

A shop vac

It might not come as an obvious inclusion, but the value of a shop vac can't be discounted. Many beginner woodworkers see the price tag of a mid-range shop vacuum and think to themselves that this money could be better spent elsewhere. Buying better power tools and even hand tools may seem like a more important use of resources at this phase. But there's really no substitute for a good quality shop vac.

Certainly, you could spend your time at the end of a building session sweeping up the remnants of your work. But there are far more efficient approaches to this clean up task than breaking out the broom and shovel. Most woodworkers will create a far bigger mess than they expect when handling even small work pieces. Dimensioning boards, sanding components, and creating off cuts when notching out dovetails and other joinery elements all leave behind a huge mess that only grows as you increase your skill and productivity.

An effective vacuum will keep your workspace clean and tidy. This will clear your head, too, and allow you to focus on the jobs that matter. A wet/dry option is your best bet when seeking versatile cleaning power that can be used in the woodworking arena and beyond for other projects. A good, cost-effective starting point is the Stanley 4-Gallon Wet/Dry Vacuum.

Thickness planer

Moving into the more advanced sphere of woodworking, a thickness planer is one of the first tools you'll want to invest in when making the leap from beginner woodworker to experienced creator. Like a hand plane (or even a powered alternative to the traditional tool), the thickness planer is a robust workpiece dimensioning tool. This piece of equipment may be found as a large floor model, or as a bench-top variant (such as the 15-amp DeWalt planer) that can be taken on the go.

Woodworkers progressing in their vocation will typically want something that resembles a tool rather than a piece of shop equipment for their workspace (like the 13-inch Jet stand planer). A full-sized model will cost you significantly more, but the massive jump in productivity can really set you on course for more professional woodworking tasks.

A thickness planner features a cutting head with multiple blades that rotate rapidly within the tool's body. As you feed a board into the planner, it will automatically churn through and cut the board, shearing off high spots to create parallel faces as it exits the other end.

Jointer

All woodworking pros own a jointer. Used in coordination with a planer and table saw, this tool is instrumental in processing rough lumber into perfectly square boards with four 90-degree corners. Anyone serious about top-quality woodworking projects will need this tool eventually. However, there are caveats. Jointers are expensive, take up considerable space in your workshop, and aren't particularly useful beyond the processing phase — unlike other tools that can perform multiple duties.

If you are ready to really level up your woodworking capabilities, a jointer is the next step in your journey. Professional floor models like the Powermatic 8-inch jointer won't come cheap, but they offer professional-level performance. Alternatives, such as the Rikon 8-inch benchtop model, can drastically reduce the price while also featuring a more basic operation.

Installing a jointer in your workshop vastly improves the finished products you can create, introducing an extreme precision upgrade. However, this platform may require specialized installation and will occupy a lot of space in your work area. There's a reason why most woodworkers don't have a jointer, and it's not for a lack of desire.

A sander (and likely a collection of them)

Returning to power tools more commonly found within the kits of everyday woodworkers, a sander is a genuine priority that everyone can and should have at their disposal. Sanders come in a huge range of options. An orbital sander features a circular disk shape and rotates as it delivers sanding power. Belt sanders and sheet sanders offer different approaches to material shaping and smoothing processes. You might also consider a benchtop sander (such as the WEN Oscillating Belt and Spindle Sander) that operates in much the same way as your bench grinder. However, this tool features sanding accessories rather than standard metal shaping options.

Sanders generally won't hide behind knowledge barriers or feature-rich arrays that make them cost-prohibitive. The sander is a fairly humble tool, no matter what type you use. Orbital sanders are a great starting point (like the cordless DeWalt or corded Skil variants), and they deliver a clean, smooth finish to just about any workpiece. For larger material removal tasks, a sheet sander or even something larger might be more appropriate. Ultimately, the task you are working on will determine which sanding tool provides the best performance. In many instances, woodworkers will build a collection of sanding equipment.

Biscuit jointer

A biscuit jointer is a power tool that veers decidedly away from the standard fare you might expect to see in a workshop. Renovators and others who aren't working primarily with wooden build parameters won't really need this specialized tool. However, woodworkers often find the use of biscuits to be instrumental in their joinery tasks. During glue-ups, woodworkers aim to increase the surface area shared by the two pieces that come into contact. One way to do this involves cutting joinery elements into the connection. A tight fit with interlocking pieces does some of the heavy lifting, and the added surface area provides a greater total volume space for the glue to create a hold within.

Biscuits are one option that woodworkers frequently rely on for this task. This involves cutting small grooves into the hidden faces of these connections. Once this is done, inserting biscuit pieces into these recesses offers a significant increase in grip strength for the glue-up. Biscuits work much like dowels, but they are a little more versatile because they frequently incorporate a thinner, longer structure that provides expanded surface area. Biscuits can also be used in more delicate work pieces for this reason. The biscuit jointer is a tool specifically designed to cut these channels, and you'll frequently find that cutting them by hand is either impossible or extremely difficult. The Ryobi Biscuit Jointer Kit is a solid example that can greatly improve your final builds.

Drill/driver or impact driver

The last tool on this list is a common sight among makers of all types. Drilling holes and fastening things together with screws is a core competency, no matter your work's focus. Traditional woodworkers typically do not want to incorporate screws or fasteners of this nature into their designs. However, they can benefit from having a drill of some kind on hand.

One area where this tool can be particularly beneficial for a woodworker is addressing a lack of clamps. If you don't have enough clamps in your workshop, sinking a few temporary screws into the hidden areas of your workpiece as the glue dries helps secure your product as it sets. If you aren't able to drill screws into your workplace, building a temporary clamping structure with off cuts and scrap timber is another option to bridge this seemingly impassable gap.

Altering parts of your workshop or even building a new bench to support growing needs in the space will typically rely on standard fastening solutions rather than traditional joinery. An impact driver can help you secure materials, but a drill/driver often provides more than enough power to get the job done. This tool packs drilling and fastening capabilities in one tool, whereas an impact driver only delivers a single function. In our rankings, DeWalt is the best drill brand available, and its 3-speed hammer drill is a fantastic choice.