Ford's EV Production Is The Innovative Future We Never Saw Coming

Having stuffed order books for your electric vehicles sounds like the definition of a good problem, but Ford can't afford to wait as it tackles its production challenges. The reception to the F-150 Lightning, Mustang Mach-E, and E-Transit has been close to universally positive, with demand far exceeding supply. Yet with rival electric trucks, SUVs, and cars arriving all the time, expecting would-be buyers to be patient isn't a solution.

That's where the tech-savvy team at Ford e — hewn off into a standalone business to focus on electrification, while Ford Blue Oval concentrates on internal combustion — comes in, wielding talents and techniques more commonly found in big tech firms to improve and accelerate EV production. In the process it's developing the next generation of Ford's vehicle architecture, an endeavor far beyond merely the infotainment system drivers will find on their dashboard.

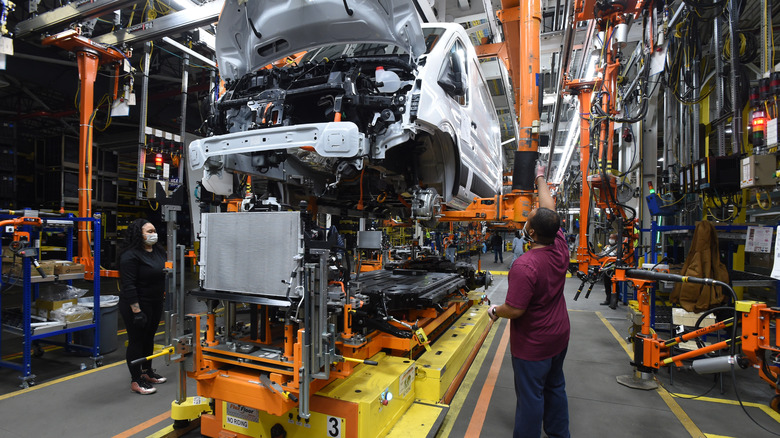

In fact, it'll see everything from autonomous driving to self-diagnosing software woven through the production process, as the nuts and bolts (and high-voltage batteries) of building electric cars attempts to match the breakneck pace of Ford's traditional truck and car lines. That's an ambitious goal but, as some of the key players at Ford e explained during a roundtable discussion at Ford's Detroit facility which SlashGear attended this week, it's also a chance to demonstrate why the future of transportation is more than just a vehicle that can drive for you on the highway.

A team with serious tech background

It was a rare opportunity to hear Doug Field, Chief Advanced Product Development and Technology Officer at Ford e, not only to speak but to introduce some of the key lieutenants as his division reshapes the automaker from the inside out. Field rejoined Ford in September 2021, after a three-year stint at Apple where he was believed to be leading the so-called "Project Titan" autonomous car division. Before that, the engineer spent five years at Tesla, helping develop its electric cars.

It's a role that gave Field a front-row seat to the headaches of ramping production, particularly when your product is as much a gadget as anything else. Tesla's "production hell" — as Elon Musk memorably described it — is now something its fellow automakers are painfully aware of, with the COVID-19 pandemic and the ensuing supply chain crunch leaving most struggling to build enough vehicles to meet demand.

Both Apple and Tesla have been deep in the self-driving car challenge, meanwhile, with mixed results. Tesla's "Full Self-Driving" package is rolling out in public beta, albeit without the actual unsupervised driving features usually associated with autonomous driving. If the leaks are to be believed, meanwhile, Apple has dialed back its own self-driving ambitions, aiming to get an electric car out by 2026 that will, at least, have some autonomous highway functionality.

Driverless cars before they even reach owners

The eye-catching part of Level 4 autonomy is the idea of handing over full control of the vehicle, to the vehicle. What might show up first, however, is an application of "full" self-driving that takes place before the driver even gets their new Ford — but which could get them their new vehicle faster. That's because Ford is looking to use ADAS (Advanced Driver Assistance Systems) as a way to accelerate production and help remove human workers — and even accommodations for human workers — from space-constrained factories.

Ford isn't the only automaker looking at that, mind. BMW is testing its own autonomous driving systems to take the new 7 Series luxury sedan around its Dingolfing plant, navigating the car from the initial testing area to the finish area, and then through to the dispatch point.

Level 4 could show up first in Ford factories "to help the teams that build the product," according to Field. For example, currently, vehicles are driven around the factory — such as from the production line to testing — by a human driver. ADAS and self-driving could take on that role in the future, a digital chauffeur that could even stack EVs more closely together since there'd be no need to leave a gap to open the doors. That might not sound like much, but at a time when Ford is "blowing up the walls and using every tiny piece of space and roof right now to be able to build more F-150 Lightnings" at its Rouge Electric Vehicle Center, according to VP of EV Industrialization Lisa Drake, clearly, every little bit helps.

Fixing problems when they're created

With the greater role of software, Ford is also exploring how the testing process is undertaken — and how efficiency could be built into the production line as a whole, rather than waiting for a separate process at the very end. With a software-defined electric vehicle, compared to a traditional internal combustion version, there's less of a focus on mechanical testing and more on making sure the software and hardware are working together as they should.

One way to improve on that, according to Drake, is a so-called "Digital Partner" within the software itself. Rather than have testing wait until the EV is at the very end of the line, the software is tested in-station as it moves down that line. Operators at each station get real-time feedback so that they can fix any errors as they arise.

It has required a whole new approach to software development within Ford's EVs. "We're also building a lot more diagnostic tools for everything covered in every part of the stack, so that when you're developing you can diagnose what the problems are, as well as later on through the production process," Roz Ho, Chief Connected Vehicle Software Officer for Model e, explains. "Right now, some of the things we always spend time with is at the end of the line, after we do all the integration, finding little problems. We're going to put in enough diagnostics in our software so that we can find and fix those problems before it leaves the factory."

The supply chain challenge

Having that efficiency requires, mind you, that the chips actually run that software. It's an ongoing challenge that Ford isn't alone in facing, as supply chains struggle to come back to full capacity after the height of the COVID-19 pandemic. Ford was forced to stockpile trucks due to missing microprocessors, only delivering them in 2021 when suppliers could catch up. Earlier this year, General Motors had to park around 95,000 vehicles temporarily, until it could source the missing components that would allow it to complete production.

Right now, though Ford e has team members with chip design backgrounds and expertise, Ford doesn't build its own chips. It does, however, make requests of its suppliers to customize what chips it buys will do, and it works with suppliers on improving their code-writing skills.

"We're always looking to where we can add differentiation," Roz Ho explains. "So the parts where we think we can do a better job with differentiation, we're going to do in-house."

The future of Ford EVs doesn't care about wheels

Beyond that, though, Ford e is an opportunity to develop electric vehicles beyond just methods of transportation. "Entertainment and gaming is going to be a huge area of focus," Alex Purdy, Head of Digital Product, suggests, "particularly given EV ownership is chaining the way that people think about their vehicles, they're using it in totally different use cases."

We've seen companies flirt with that prospect when it comes to autonomous vehicles. After all, if the EV is driving itself, that frees up plenty of time for the human who once was in control to do something else. The goal, though, might be an electric car that you choose to sit in — even if you don't have anywhere to go.

"Our aspiration going after a lot of these use cases is, if we truly succeed, you could take the motors and the wheels off and you still have a product," Field says.

As for when we can expect to see all of this begin to arrive, Ford won't be drawn on specifics. The goal, Field explains, is to have this new, next-generation platform and architecture ready to land alongside the next generation of electric vehicles. Given the F-150 Lightning and E-Transit are relatively new in production, and the Mustang Mach-E wasn't all that early before that, we could have some time to wait. Nonetheless, the bigger news in the meantime is the upcoming BlueOval City plant in West Tennessee, with production there expected to begin in 2025.