12 Things You Didn't Know About The LML Duramax Diesel Engine

We may receive a commission on purchases made from links.

The Duramax 6.6L V8 diesel engine was a huge moment for General Motors' heavy-duty trucks. Even though it looks pretty similar on the outside to the old LMM generation, underneath the hood and deep in its structure, the LML was a new shift. It was the last, most advanced version of the original Duramax design philosophy that started way back with the LB7.

It was the most powerful Duramax out there when it launched. However, the real significance wasn't just the power output, but the serious, almost surgical engineering work needed to meet increasingly strict federal emissions rules while also cranking up the power and making it drive better. GM engineers executed some big changes and built a really high-pressure, technologically dense diesel machine.

The LML Duramax was an advanced engineering response to modern diesel demands, preserving durability while reducing emissions through innovations like the ninth injector, fast piezoelectric injectors, and a 30,000 PSI fuel pump. Though quiet and quick-starting thanks to glow plugs, its complex, high-tolerance components meant it needed regular maintenance. This article goes over twelve critical, often-overlooked changes that pushed this classic Duramax to its limit.

The ninth injector

The implementation of the Hydrocarbon Injector, which is called the ninth injector, is one of the biggest mechanical improvements the 2011 LML Duramax brought in. Older engines used to inject fuel right into the cylinders during the exhaust stroke to handle regeneration, but that process ended up washing down the cylinder walls. The LML fixes this by using a dedicated hydrocarbon injector placed right in the exhaust stream.

Before this, the LMM generation relied on the engine's eight main fuel injectors to spray raw diesel into the combustion chamber after the main burn was complete. This post-injection successfully added fuel to the exhaust system to burn off soot in the Diesel Particulate Filter, which is something you may not know about diesel engines. It had a massive mechanical issue called cylinder washing. The unburnt fuel would frequently sneak past the piston rings during the exhaust stroke.

By moving this function to a dedicated injector situated in the turbo downpipe, right before the Diesel Oxidation Catalyst, General Motors completely eliminated the danger of fuel contaminating the engine oil during those regeneration cycles. Since the "ninth injector" runs totally separately from the engine's normal combustion cycle, the LML can kick off regeneration without having to mess with the engine tuning or risking cylinder wall integrity.

Piezoelectric precision

The LML upgraded the piezoelectric fuel injectors to handle more pressure. These injectors allow for up to seven separate injection events during a single combustion cycle, which really helps smooth out the idle and cuts down on that loud diesel clatter you usually hear. Before the 2011 LML came out, General Motors relied on solenoid-style injectors for the LB7, LLY, and LBZ engines, which used electromagnets to control the fuel valve.

The move to piezo technology was a massive jump forward in hydraulic response time. Instead of the traditional solenoid, the LML's injectors use a stack of piezoelectric crystals. When the Engine Control Module (ECM) hits them with a high-voltage charge (sometimes up to 250 volts and 20 amps), those crystals immediately expand to lift the control valve and start the injection process. This reaction happens in microseconds, which is significantly faster than the magnetic fields in the older generations could ever hope to manage.

This incredible speed and precision let GM engineers tune the LML for pilot injection events. That's when a small amount of fuel is squirted into the cylinder milliseconds before the big main burn happens. This dramatically reduces the typical rattle you associate with heavy-duty diesel trucks.

A big pressure jump

General Motors needed to meet strict federal emissions rules while also boosting outputs of up to 400 horsepower and 765 lb-ft of torque. To do this, GM cranked the fuel rail pressure up to an incredible 30,000 PSI. This was a massive leap from the 26,000 PSI maximum found in the older LMM and LBZ engine platforms, which are a few years back in the diesel engine generations.

This boost wasn't arbitrary; It was an engineering necessity, designed to basically pulverize diesel fuel into a significantly finer mist than before. Superior atomization makes sure the fuel mixes more thoroughly with compressed air, which results in a cleaner, more complete combustion event that lowers particulate matter emissions and improves your fuel economy by about 11 percent.

Handling this high-pressure environment required GM to completely overhaul the injection hardware. The company replaced the previous Bosch CP3 pump with the Bosch CP4.2 high-pressure fuel pump, a component built specifically to generate these extreme pressures, even though it flows roughly 20 percent less fuel volume than the CP3 it replaced. The combination of the 30,000 PSI rail pressure and the rapid-fire capability of piezo technology allowed the LML to execute multiple distinct injection events per combustion cycle.

B20 compatible

The LML Duramax was the first one officially certified to handle B20 biodiesel. This wasn't just them shuffling certification paperwork around; It meant doing a massive hardening job on the whole fuel system. GM engineers upgraded specific seals and gaskets so they could stand up to the ester content in biodiesel. If you don't do this, that ester content acts like a corrosive that eats away standard rubber components really fast.

Besides toughening up the lines and seals, the LML brought in some essential hardware designed specifically to handle B20's physical characteristics. Biodiesel loves to attract and absorb water, so the LML got a better fuel filter that includes a coalescing element that helps with water separation. Also, the B20 gels and waxes way more easily than regular diesel when it's cold out, so GM threw in extra heating for the fuel circuit. Basically, there are many differences between diesel and biodiesel, so your engine matters a lot.

The ninth injector injects the fuel straight into the turbo downpipe for the regeneration cycle; By doing this, the LML completely removes that oil dilution risk. This makes sure that using B20 won't going to compromise your engine lubrication or its lifespan. Just remember that GM suggests using biodiesel blends that meet ASTM D7467 specifications to guarantee engine performance and longevity, since this is what the engine was tested with.

Piston cooling jets

Since it had to deal with the 397 horsepower's increased heat load, General Motors ramped up the oil pump flow and added specific oil jets that spray the bottom of the pistons for serious cooling. This wasn't just a tiny tweak; The LML needed an oil pump that could push 11 percent more volume than what was in the older 2001 through 2010 Duramax engines.

To fit this higher capacity pump and handle the huge jump in lubrication needs, General Motors had to reengineer a big chunk of the engine's bottom section. This meant using a new front cover, a redesigned oil pickup, a different windage tray, and updated upper and lower oil pans.

The actual design of the piston cooling nozzle assembly has a clever failsafe built right in, which protects the engine when it's idling or running at low RPMs. The bolt that holds the cooling nozzle has an internal check valve made up of a spring and a ball. This valve is set up to open only when the engine oil pressure goes above about 30 psi. This is smart because it makes sure the system saves essential oil pressure for the really critical bearing surfaces when you're just idling, instead of needlessly spraying the pistons.

Metallic glow plugs

The LML uses great metallic (steel-sheathed) glow plugs, specifically the ACDelco 9G. They make sure you get rapid starts, even when it's freezing outside. These quick-glow elements are significantly better than previous versions; and no, they aren't just fancy intake heaters.

That fast heating process is all controlled by a smart piece of gear called the Glow Plug Control Module (GPCM). This system uses pulse-width modulation, which is how it monitors and adjusts the electrical current for every single start based on the ambient conditions. The module sends a precise flow of voltage to the 11-volt system to achieve a quick heat soak, and then it regulates the current immediately afterward to maintain the temperature without burning out the element.

While these metallic plugs are different than ceramic ones, they still wear out significantly. There's a high risk of carbon buildup and thread corrosion, but there's also a standard service requirement of replacing the plugs whenever you take them out. If you pull a plug for any reason, like during a cylinder head service, you have to throw it away and install a new one to avoid potential failures down the road.

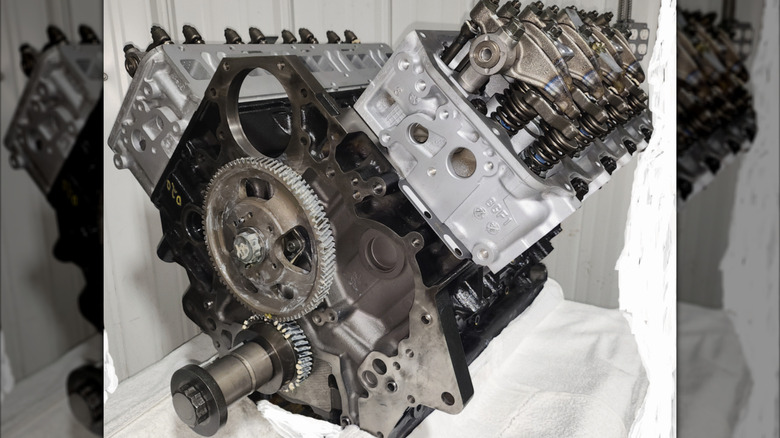

Improved deep skirt block

The LML Duramax kept the general architecture of its predecessor, but the 2011 release introduced a block casting that was significantly improved for better durability. The deep skirt design itself wasn't new to the LML, but the block received an improved casting process using a dense gray iron alloy. This updated block casting was engineered to be astronger version of the classic Duramax architecture produced up to that point, specifically designed to handle higher output without compromising longevity.

An improvement in this deeper skirt block was the implementation of a revised main bearing profile, which was optimized to improve oil film thickness in this area. This makes sure the crankshaft stays lubricated under the heavier loads generated by the new injection system. The LML also continued the use of cross-bolted main bearing caps, a feature that works with the deep skirt design to lock the crankshaft into place and minimize cap walk under high torque conditions.

Securing the main caps vertically and horizontally through the skirt makes sure the block maintains structural integrity. This holds true even as cylinder pressures reach new heights, with the introduction of 29,000 PSI piezo injectors.

Intake throttle valve

Unlike the older mechanical diesels, the LML uses an electronic throttle valve right on the intake. Its purpose is to help manage the EGR flow and cut off the air supply for a much smoother, shake-free engine shutdown. The LML uses this electronic throttle valve specifically to regulate intake manifold pressure. This is a critical function for managing the engine's emissions systems.

By partially closing and restricting fresh airflow, the valve creates a specific pressure difference that lets the Exhaust Gas Recirculation system function more effectively, boosting EGR rates to reduce NOx formation. High-compression diesel engines can shudder when you cut the ignition, which is caused by the engine fighting against cylinder compression as it spins down. The LML's electronic valve mitigates this by completely shutting off the outside air supply when you turn the key off, starving the engine of air to make sure there is an immediate, smooth stop.

Owners should keep in mind that this system performs self-checks. Any noises you hear from the engine bay after shutdown are often just the intake airflow valve cycling through its normal operating range, which is a standard condition and not a sign of failure.

Connecting rod limits

Even though the block is much stronger, the powdered metal connecting rods are still a major weak point of the LML. If you push the tuning past that 600 to 700 hp level, they can become a liability. That is higher than most of the highest horsepower muscle cars ever made, so it's a hard number to reach. Still, General Motors put the LML connecting rods on a diet; It designed them to be lighter than the rods in the older LBZ and LMM engines, and even lighter than the original LB7 units, coming in at about 1,130 grams each.

Dropping this reciprocating mass was meant to improve the engine's efficiency and give you better throttle response, using a fractured or cracked cap design to make sure the fitment and alignment on the crankshaft journals are perfectly precise. However, this effort to optimize efficiency really sets a clear performance ceiling for high-horsepower setups.

On the preceding LBZ and LMM engines, the cast-aluminum pistons were the main point of failure, and could crack along the wrist pin axis. The LML fixed that piston durability issue by removing the wrist pin bushings and reinforcing the support area.

Vacuum pump loss

The 2011 to 2016 LML Duramax generation completely got rid of the vacuum pump. On previous versions of the 6.6L diesel engine architecture, specifically the LB7, LLY, LBZ, and LMM, a vacuum pump was a standard fixture. Its main purpose was running the exhaust gas recirculation valve, a critical component for managing combustion temperatures and NOx emissions.

Depending on vacuum pressure added unnecessary complexity to the engine's front accessory drive and created a mechanical failure point that could compromise the emissions system. The LML modernized this whole setup by moving to a fully electronic EGR valve, which meant the vacuum pump was obsolete. Basically, by using an electric motor for actuation instead of vacuum pressure, GM engineers could pull the vacuum system entirely off the engine.

This got rid of the complex accessory drive, reduced parasitic loss, and eliminated the maintenance headaches associated with vacuum pumps, lines, and diaphragms that could crack or plug up once they aged. This major shift was part of a wider redesign that involved nearly 60 percent of the LML's internal components, with the objective of meeting stricter emissions rules and improve durability.

Fuel cooler

Since the fuel is compressed to such high PSI, it gets incredibly hot. This makes the fuel supply a potential heat source that has to be managed to prevent your system from degrading. To fight this, the LML has a dedicated, radiator-style fuel cooler mounted on the frame rail right in front of the fuel tank. It cools the return fuel before it re-enters the tank.

The LML's fuel system is intentionally set up to circulate more fuel than the engine actually burns during combustion. This extra fuel is used to lubricate and cool the complex internal parts inside the piezoelectric injectors and the high-pressure pump before it gets sent back to the tank. This passive cooling setup helps keep the fuel density correct for the best engine performance and preserves the lubricity needed to protect that high-pressure fuel system from overheating and failing early.

End of an era

The LML holds a special spot in automotive history, alongside the LGH, because it represented the final evolution of the classic Duramax design. This lineage started way back in 2001 with the LB7. For sixteen years, General Motors refined this specific V8 diesel architecture through the LB7, LLY, LBZ, and LMM platforms, finally reaching its peak with the LML and LGH. These engines pushed the original design to the absolute limit of what it could handle, which is why the LML was used for so many years.

When the L5P showed up in 2017, that was the end of the line. It broke the continuity, effectively making the LML the last stand of the core engineering principles that defined GM heavy-duty trucks for 15 years. Sure, the L5P still carried the Duramax badge and the familiar 6.6-liter size (4.06-inch bore and 3.90-inch stroke), but it was basically a completely new engine. Unfortunately, you couldn't swap parts between it and the LML.

The L5P Duramax represented a massive shift from the LML, with a totally new, heat-treated, induction-hardened cast iron cylinder block. It also had overhauled aluminum cylinder heads with different porting and layered coolant passages, to handle much higher cylinder pressures. Also, the LML was the last to use a Garrett variable-geometry turbo before the 2017 switch to an electrically-actuated BorgWarner unit.