11 Things You Might Not Know About Diesel Engines

With labels stating "diesel fuel only" and the existence of separate gasoline and diesel pumps, most people know there are distinct differences between gasoline and diesel vehicles that go beyond the funky smell of the latter's exhaust. Furthermore, most people have some awareness that putting diesel fuel in your gasoline-powered car is some kind of sin that will bring the wrath of the car gods down upon you should you even attempt such an act. The truth is that fundamentally, both types of engines share most of the basic principles of operation, but go about the task of converting liquid fuel into kinetic energy in differing methods.

There are reasons why diesel engines are found in buses and dump trucks while gasoline engines are found in motorcycles and sports cars. They use different fuels that have different requirements for how the fuel is burned. However, it's likely safe to assume you have little knowledge of how this is accomplished if you have no formal or even informal training in auto mechanics. I have both. I graduated from technical school in an auto technology course and have worked in the auto repair industry for many years. While my experience deals largely with gasoline engines, I know the fundamentals of both and the many idiosyncrasies between them. Therefore, I have a dozen bits of information regarding the humble diesel engine you may not know, and hopefully you will learn something new.

Spontaneous combustion

While the idea of spontaneous combustion of humans has been a topic in pop culture with wild speculation and occasional lambasting, it is not a real phenomenon, except in a diesel. Converting diesel fuel into kinetic energy, the energy of motion, requires first converting the fuel into heat by igniting it. A diesel engine accomplishes this by getting the fuel to combust, although saying it is spontaneous is not exactly correct as it is done in a highly controlled manner.

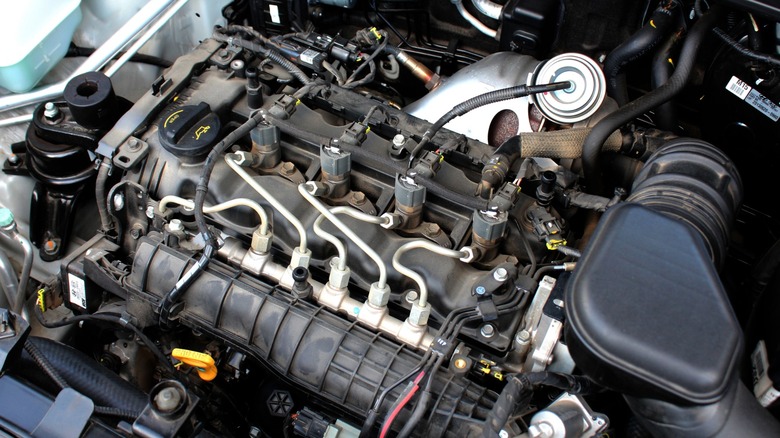

Gasoline engines work by mixing atomized fuel with air, compressing it within a cylinder, and firing a spark plug to set off the combustion, or power, stroke. Diesel engines use a similar method but do so without a spark. The compression ratio of a diesel engine is much higher than that of its gasoline counterpart. One of the byproducts of compressing air is the generation of heat. Therefore, diesel engines take in air and highly compress it to the point that it reaches an extraordinarily high temperature. When the air becomes sufficiently heated, an injector sprays diesel fuel into the cylinder, causing combustion to happen instantly. This is the primary and fundamental difference of a diesel engine.

So combustion of diesel fuel is not exactly spontaneous, but now you know why they don't have spark plugs. They do have glow plugs, however. These are used only when the engine is cold, to heat the chamber enough to facilitate combustion on startup.

Runaway diesels

Because a diesel needs no spark plug, it can run without any electricity so long as the fuel is being pumped mechanically, which is typical. Therefore, the only way to shut down a diesel engine is to cut off the air or fuel supply. Cutting electrical power does nothing. However, sometimes when conditions are just right, a diesel engine can go into a state in which it will continue to run indefinitely, often running a higher and higher rpm until something intervenes, such as catastrophic failure.

A runaway can happen for many reasons, and it can be dangerous. Runaways usually happen when an alternate fuel is introduced into the cylinders. This can be an oil leak, for example. As that oil is burned, even cutting the fuel off will do nothing as the engine will continue to draw in and burn engine oil if it has enough supply. This can also cause it to overspeed, running at a dangerous rpm, leading to flames and many broken engine parts.

The only way to stop a runaway is to cut off the supply of air. This will choke the engine and deprive it of oxygen to burn with the fuel. Runaways can happen to trucks on the road, stationary industrial engines, and even passenger cars. The best prevention is proper maintenance.

Two-stroke diesels

Two-stroke engines are found in homes everywhere powering weed trimmers, chainsaws, and dirt bikes, among other equipment. These engines were found in some early Saab automobiles, but have had few other applications in larger vehicles. In a two-stroke, power happens on every revolution, made possible by the use of ports that draw in fuel and air and hold it within the engine. It then enters through another port to replace escaping exhaust gasses heading through the exhaust port. It is ideal for small engines but becomes problematic as they get larger. However, many diesel engines over time have been two-stroke, even on the big rigs hauling freight and machinery.

Two-stroke diesel engines work in mostly the same way as a chainsaw engine but with a few differences. A power stroke still occurs on every revolution and it still draws in air through a port, but diesel fuel is injected into the cylinder at the proper time for combustion to occur. Furthermore, many, if not most, of them have exhaust valves. Additionally, a turbocharger or supercharger is needed to force air into the cylinders in these applications. Unlike a chainsaw, which requires oil in the gasoline for lubrication, diesel two-strokes have a sealed crankcase with its own lubrication.

Stricter emissions controls have caused most of these engines to be retired. Two-stroke Detroit Diesel engines used to dominate, but they are today dying breed.

[Featured image by Thomas Vogt via Wikimedia Commons | Cropped and scaled | CC BY 2.0]

Flat cylinder heads

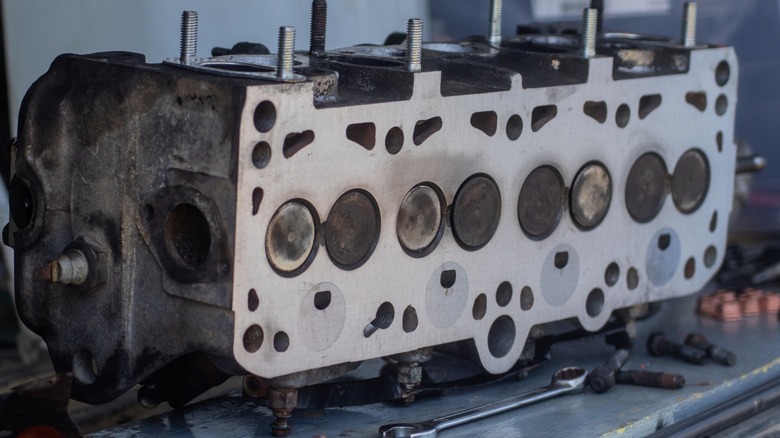

Most average drivers likely have no clue what the shape of anything inside the engine is, and that's fine. But for people with some exposure to the inner workings of automobile engines who have not been around diesels much, the shape of the cylinder heads can be a bit surprising.

In most gasoline engines, pistons are mostly flat and the heads have a concave pocket used for compression of the combustion gasses. That is called the combustion chamber. Most large diesels do not have this. Instead, the head is almost completely flat while the pistons carry a combustion bowl in a hollowed-out portion at the top. Many have a bit of a point in the middle to direct the spray of fuel outwards to facilitate even combustion, but the valves are all lined up on a flat plane across the head.

This may not be super revelatory for anyone who has been around diesel engines. But for some who have worked on gasoline engines for years, seeing a diesel head removed from a block can be surprising to say the least.

Diesel engines can burn seemingly anything

You may be familiar with the concept of biofuels and systems built for diesel engines to run on discarded fry oil from hamburger stands. This is possible due to many capabilities inherent to the design of a diesel engine and its ability to extract energy from fuel.

While vegetable oil and crude oil are quite different on the surface, they both contain hydrocarbons, and these are the molecules that can be burned for energy. Every oil possesses a different amount of potential energy based on the present hydrocarbons, but burning them can produce energy to some degree. Diesel contains more hydrocarbons than gasoline, for example. Regardless, when compressed and raised to a temperature above the flash point, fuels will combust and burn the hydrocarbons, which is why fry oil can be used as fuel.

Additionally, diesel engines can burn other fuel possessing hydrocarbons. Some fuels include kerosene, biodiesel made from crops, and jet fuel. The U.S. Marine Corps uses Kawasaki motorcycles with diesel engines to take advantage of a "single fuel for all equipment" policy, and that fuel is JP-8, or jet fuel. Volvo is working on a dimethyl ether fuel system similar to compressed natural gas systems for cars, and technically, a diesel engine can even burn gasoline, although not well nor for very long.

Diesel can be cleaner than gasoline

If you thought diesel engines were naturally dirtier than gasoline based on the clouds of fuel billowing from smokestacks of big rigs, you may be wrong or possibly have a misunderstanding. The measure of a fuel's dirtiness based on emissions outputs has more to do with which specific emissions you are measuring and nothing to do with what we can see. There are the chemical emissions from the gasses being expelled and fuel particles called particulate matter. Both are of concern for the environment.

The discussions of fuel emissions are nuanced and consider many variables. For example, diesel exhaust contains more carbon dioxide (CO₂) than does gasoline exhaust, but higher fuel efficiency negates the difference in overall driving. Furthermore, diesel exhaust contains no carbon monoxide (CO) at all while CO is a concern for gasoline engines and has indirect negative environmental effects. Furthermore, diesels emit high levels of particulate matter than gasoline engines, which are microscopic carbon-containing particles. EPA regulations from 2007 mandate diesel particulate filters, thus reducing particulate matter on modern diesel engines.

The claim that diesels burn cleaner is not universally true and does not apply to individual engines. When applied across populations and all vehicles, a case can be made that this is true. However, when you see someone "rolling coal," a practice banned in at least six states, you are seeing an improperly tuned engine engaged in illegal behavior and massively polluting. No, that is not burning diesel cleaner.

Diesel engines are energy efficient

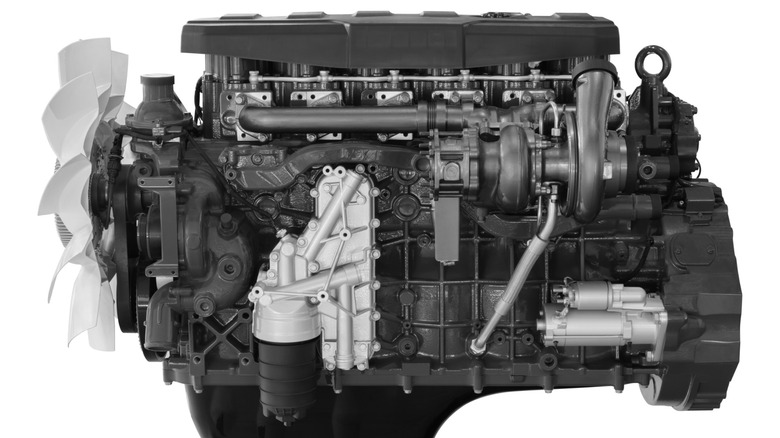

Large diesel engines are the standard for large vehicles. Semi-trucks, earth movers, farm tractors, and army tanks all burn diesel, just to name a few. Most people know this to be true, but maybe never considered why. The reason is efficiency.

Diesel engines are good at delivering high torque levels at low speeds, making them ideal for hauling and heavy work applications. Diesel fuel is also about 15% more energy-dense than gasoline, and that efficiency is compounded by the efficient means of burning the fuel in a diesel engine. While there are dozens of differences between the two types of engine, the bottom line is that diesel engines are more efficient than gasoline engines, and that helps to drive their popularity in heavy-duty applications.

It's interesting to note that gasoline engines were used in heavy-duty applications for many years, including a 1948 Peterbilt 354DT, for example. But by the 1960s, diesel power had become the standard for commercial trucking. It just took some time for manufacturers to perfect the technology.

Diesel manufacturers pioneered turbochargers

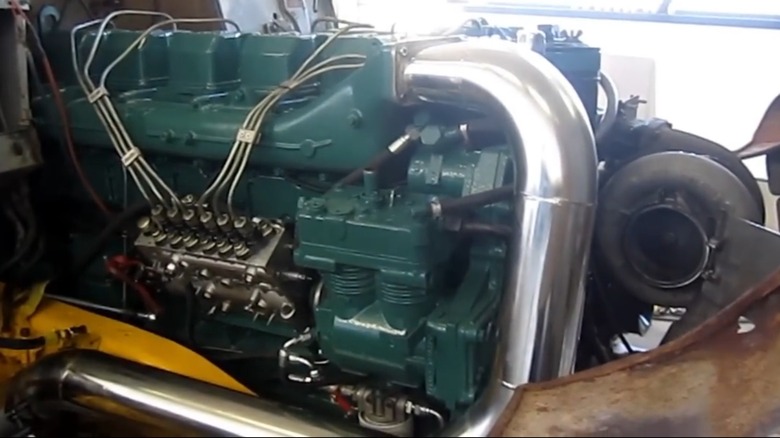

Porsche made history when it introduced the first of a long line of Turbo 911 models in 1974, and GM perhaps started the turbo trend with its Oldsmobile Jetfire in 1962 and Chevrolet Corvair Monza Spyder in 1962. While these cars represent the early days of turbocharging cars, it was already an old hat in the world of diesel power.

The first turbocharged engines came after Alfred Büchi received a 1925 patent for his invention, the culmination of 20 years work. Turbos immediately saw use on a variety of heavy-duty applications, primarily on large diesel engines such as those in locomotives and large boats. European truckmaker Scania claims to have produced the first serial production turbo engine in 1951 with its 11.3-liter D810, an industrial and marine model, and fellow Scandinavian Volvo followed a few years later in 1954 with its L395 Titan, the first semi-truck with a turbo diesel.

Since those early years, turbos became standard components on diesel equipment, particularly long-haul trucks that require maximum power and speed for hauling. While turbos are commonplace on automobiles today, they might not be if it weren't for the early developments taking place in the world of diesel power.

Refiners used to discard diesel fuel

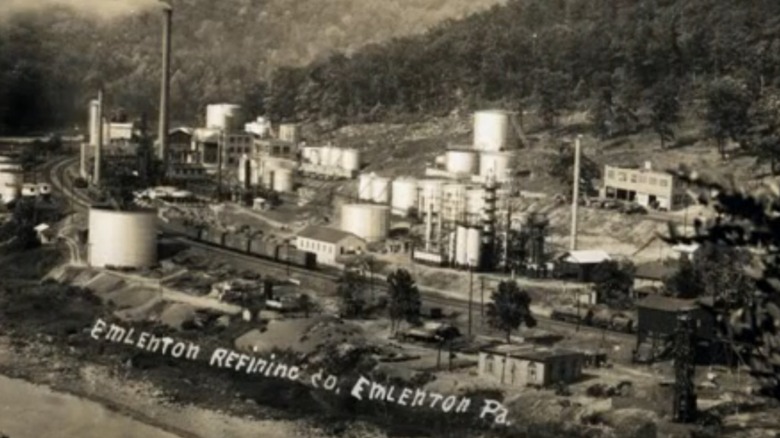

The diesel engine exists as a result of the work of a brilliant engineer named Rudolf Diesel, who first applied for a patent describing a new kind of internal combustion engine in 1892. A lecture at Royal Bavarian Polytechnic of Munich spurred Diesel to create a new kind of engine as he learned the existing engines of the day only converted about 10% of energy used into useful work. He theorized that he could achieve a much higher efficiency, eventually accomplishing this task by realizing 25% efficiency with his invention.

When Diesel created his new compression-ignition engine, what became known as diesel fuel did not exactly exist. Early 19th century refineries' main purpose was originally to extract paraffin from crude oil for oil lamps. Other parts of the crude were discarded as waste byproducts. This included kerosene and gasoline, which were soon adopted for new uses. However, what we now know as diesel fuel was called distillate and continued to be tossed out.

Diesel first designed his engines to run on coal dust but discovered that one of the byproducts being thrown out by refineries might be a better choice. With a redesign of his engine and the distillate oil waste on hand, a viable engine came to life. This success brought us the modern diesel engine and the previously worthless waste product would forever become known as diesel fuel.

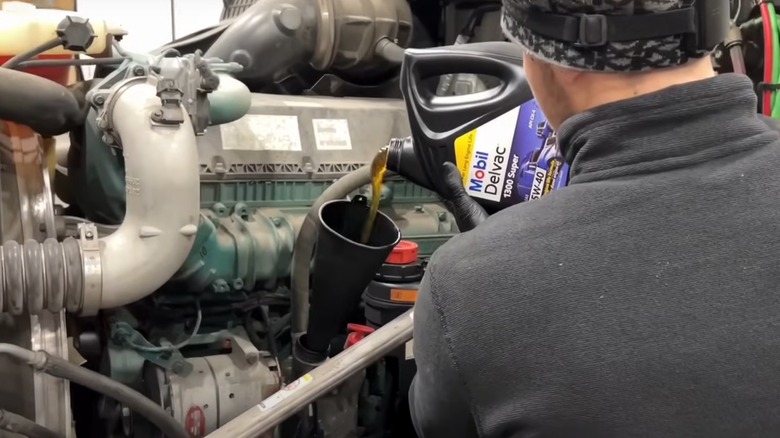

Motor oil differs widely for gas and diesel

Aside from fuel, engines need lubrication from motor oil. Fortunately, most drivers can take their cars to a service center and have the correct type of oil changed or added and not have to worry about the minutiae of motor oil.

For those times you might need to add some oil or even want to service your own vehicle, be warned that you cannot swap oil intended for gas or diesel engines into one another, even if it's on sale or your cousin hooked you up with a case that "fell off a truck." This is because all motor oils have additives. These added chemicals include rust inhibitors, anti-wear agents, and detergents to keep the engine running clean. Since gas and diesel fuel have different chemistry and are both used in engines that operate with significantly different combustion processes, the needs of each engine differ.

The key differences between diesel motor oil and conventional oil lie in the viscosity of the oils and the byproducts of combustion. With diesel engine's large size and extreme heat, thicker oils are required to prevent premature breakdown and complete coverage of all the engine components. Furthermore, the soot and particulates present in a diesel engine need specific cleaning agents to prevent buildup in oil passages. Myriad differences abound in these two oils, so the best warning to take heed is not to mix the two, lest you will have some nasty problems on the road ahead.