12 Oscillating Tool Tips Beginners Should Know

We may receive a commission on purchases made from links.

Oscillating multi-tools are a relatively new addition to the modern tool kit, and they are among the most versatile tools you can buy. While you can find them today at home improvement stores, they got their start in a totally different arena. In 1967, German power tool manufacturer Fein set out to solve a problem in the medical field by creating a tool that could cut through hardened plaster casts without cutting the fleshy human bits inside.

Unlike a rotating saw blade, oscillating blades need resistance to work, so they are only really effective on hard surfaces and materials. If you've ever had a broken bone requiring a cast, you've probably had a personal close encounter with an oscillating saw. However, it took decades for the tool to make its way out of the doctor's office and into the workshop.

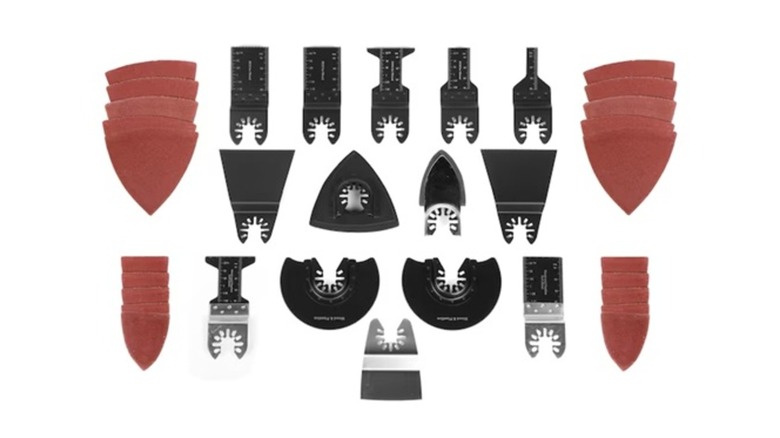

Over time, various attachments were developed to expand the oscillating saw's functionality beyond just cutting, resulting in today's oscillating multi-tools. You can find them with a wide range of blades designed for cutting, sanding, or otherwise manipulating a range of materials. If you're new to using an oscillating multi-tool, here are 12 beginner tips you should know.

Buy a cheap kit to test different blades

An oscillating multi-tool only does one thing. It creates tiny back and forth motions which jiggle a blade to sand or cut. There are a wide variety of blades with different shapes and materials which can be used for different jobs. The functionality of your multi-tool depends almost entirely on which blade you choose.

There are scrapers designed to pry goop from hard floors, carbon steel blades for cutting wood or plastic, bi-metal blades for cutting through nails and other metals, grout removal blades, sanding heads, and a whole lot more. As with any unfamiliar tool, there's a learning curve to using an oscillating multi-tool, and you can save yourself from burning money by starting with a cheap kit with a variety of blades. Starting with more affordable, low-quality blades lets you play with them, test them out, and figure out which ones are useful to you.

You can find kits from major home improvement big box stores featuring a variety of blades for under $20. At that price, you can probably afford to ruin a few blades figuring out how they work. Then you can invest in higher quality blades once you know what you're doing.

Some blades only work on certain materials

Not all blades are created equal, even if they look that same at first glance. In addition to some variety in quality from one manufacturer to another, certain blades are intended for use only on certain types of materials. For instance, a cutting blade intended for wood won't work as well on harder materials like metal.

While you might be able to get away with using the wrong blade, it's likely to get dull and break down more quickly if you're using it off label. There are also safety concerns regarding broken blades when they're pushed beyond their limits. Instead, you'll want a blade designed for use with your intended materials. Make sure to check the label to verify that your chosen blade works with metal, or whatever material you're handling.

You can find bi-metal blades, high carbon steel blades, blades made of carbide, stainless steel, high speed steel, titanium, diamond, and more. Fortunately, blades are often labeled with the materials they're good for, so you can tell at a glance which one you need, even if you've already tossed out the packaging.

How to know when a blade is dull

Even once you've chosen the correct blade, they won't last forever. Oscillating tool blades suffer normal wear and tear when you use them, and we can't expect to chop through wood, nails, and screws without chipping or getting dull.

One way to check for dullness is with a visual inspection. If the teeth are worn down or broken off, that's a good indication that your blade is ready for retirement. One of the best ways, however, is to pay attention to how it feels. A dull blade will take more time and more pressure to make a cut. If things start slowing down and taking considerably longer than normal, it might be time to replace your blades.

You can also look at the debris your cuts are creating. If it starts to look like fine dust instead of metal shavings, that's a good indicator that your blade is struggling to make progress. Without a good edge, oscillating tools rely less on cutting and more on friction. This can cause smoke, sparks, or discoloration on the blade or material. You might also notice that the sound of cutting becomes more high-pitched as the blade forces its way slowly through material.

Make sure your blade is compatible

Before you buy any blades, make sure they are compatible with your specific multi-tool. Some brands use proprietary locking mechanisms and if you buy the wrong brand, you might get home only to find that they won't lock in.

When you look at a blade, you'll notice that one end has a cutting edge and the other has a circular or semi-circular opening which attaches to the multi-tool. That opening has a specific shape and a series of holes which are used to lock the blade in place. Some brands use the same shape and are interchangeable, but not all of them. The last thing you want is to drop a bunch of money on some new blades that won't work for you.

One way to be sure is to buy blades that are the same brand as your oscillating multi-tool. If you buy Dewalt blades, you can be confident that they'll fit a Dewalt multi-tool. The same is true of Bosch, Dremel, and other major brands.

Always wear safety gear

Using appropriate personal protective equipment (PPE) is important anytime you're in the workshop, doing home renovations, or working on a DIY project, but it bears repeating. Oscillating multi-tools can kick up a lot of dust and contaminants. If you're cutting through wood, metal, drywall, or other materials, you'll want to take appropriate steps to protect yourself. Before beginning work with your multi-tool, make sure you have appropriate gloves, goggles, and a mask or respirator.

Depending on what you're doing, you might only need basic dust protection. Alternatively, you might need a specialized respirator with built-in filters to protect you from carcinogens. If your intended task could expose you to lead, asbestos, or mold, make sure you've got the right mask or respirator to keep you safe. You'll also want to get masks for anyone else in the house or workshop. Even if they aren't helping with the renovations, they'll need the same lung protection.

When using a multi-tool you might be exposed to fast-moving debris, broken blades, metal shavings, and more, all of which can cause eye injuries. Goggles help to protect your eyes from dust and injury. And a good pair of gloves are a necessity to help protect your hands from cuts, scrapes, punctures, and other injuries.

Consider the multi-tool's features

All oscillating multi-tools work according to the same principle. As the name suggests, they oscillate back and forth to jiggle a blade, creating friction to cut or sand materials. While all multi-tools are designed to perform more or less the same jobs, they vary with regard to their features. If this is your very first multi-tool, you're probably not buying a top of the line offering, but you can still get a good experience if you choose the tool that works best for you.

Some multi-tools come with additional accessories like a collection of blades or a carrying case. Some are corded, while others are cordless and powered by rechargeable batteries. Some have built-in LED lights to illuminate your workspace. Others have variable speeds, letting you adjust the oscillation rate. Taking a moment to think about what you really need your multi-tool to do before slapping cash down on the counter can save you serious headaches down the line.

Use your oscillating tool strategically

Oscillating multi-tools are so versatile that you might be tempted to use your new toy for just about every job. They can be used as a saw to cut base boards, door jambs, and pipes. You can use one to remove grout or cut tiles. A multi-tool can scrape caulk or sealant from windows or showers. You can cut holes in flooring for air vents, sand materials before painting, or cut openings in drywall for electrical boxes. Of course, using your multi-tool too often can cause broken or dull blades, it could even wear out the motor and kill your multi-tool before its time.

Before you get to work, consider whether the oscillating multi-tool is the best tool for the job. Use the multi-tool when you need to make precise cuts or work in cramped spaces, and use other types of cutters and sanders when they're more appropriate. An oscillating multi-tool is a jack of all trades. It's capable of doing many different jobs, but it's not necessarily the best tool for some of those jobs.

Use a guide to make straight cuts

An oscillating multi-tool is a hand tool disconnected from any supporting structure, which means it's only as accurate as your aim. If you want to make straight cuts (and of course you do) then you're going to need a steady hand, or a guide. When making cuts with your multi-tool, you should use a level, a square, a straight edge, or even a spare piece of wood with a clean edge and some clamps to create a guide for your cuts.

There's really no wrong answer as long as you get the support you need to keep your cuts straight. If using spare materials and clamps, pay attention to make sure your multi-tool doesn't start to bite into your guide. You can always trim away more material if you need to, but you can't put any material back. A little preparation can save you headaches and time in the long run.

Use scrap flooring to trim door jambs

There's no such thing as a perfectly built home. Despite best efforts, you'll inevitably end up with walls or ceilings that aren't perfectly square, or flooring that doesn't perfectly meet up with the wall. One of the ways we commonly hide those imperfections is with trim, floor boards, and door jambs. Of course, that doesn't mean you shouldn't endeavor to make things as clean as possible. That's where your oscillating multi-tool comes in.

One of the common ways people use oscillating tools is to trim door jambs so that flooring can slide snuggly underneath. To make your cuts as clean as possible, use a piece of scrap flooring as a guide. Place a piece of scrap flooring next to the door jamb and lay the oscillating multi-tool on top of it. Then press the tool against the door jamb, using the flooring as a guide, to make your cut. By reusing discarded material, you'll be able to cut the door jamb at precisely the right height for your flooring to slide underneath with minimal gaps.

How to protect your walls

Another common job for an oscillating multi-tool is the removal of wall trim. Wall trim is typically mounted using a combination of wood glue and nails. Finishing nails are famously difficult to remove, especially if they were installed using a pneumatic nail gun. Often, the nail heads are below the surface of the trim, and they might even be covered over with putty and paint.

Even if you could access the nail heads, they aren't usually wide enough to grab with the claw end of a hammer. The features which make finishing nails so good at their job are the same features that make them hard to remove. Sometimes, the only way to remove trim is to pry it from the wall.

The thin blade of an oscillating multi-tool can get between wall and trim to cut through glue and nails alike. Of course, pressing the blade against the wall runs the risk of scraping or otherwise causing damage. To protect your walls, place a thin piece of sheet metal under the blade. In a pinch, you can use other materials like wood or even cardboard. Just keep an eye out to make sure friction hasn't destroyed the cardboard and replace it as necessary. And remember to protect your fingers when holding anything near your multi-tool.

Start low and slow

Many tools ask you to use all of your strength to make them work. If you're cutting through tough materials or trying to loosen a stuck lug nut, you might need to put all of your body weight into the action. In fact, some tools even have pneumatic versions, which use an air compressor to provide more force than the average human body can muster.

An oscillating multi-tool, by contrast, asks for a lighter touch. When making cuts, you want to start with low pressure, push slowly, and adjust the level of force as necessary. This can be especially true when cutting through pipes and other rounded materials.

Because of the relatively narrow profile of multi-tool blades, it's easy to slip off of a pipe before you score it enough for the blade to stay in place. Starting with low pressure and slow movement reduces the risk of slipping and gives you more control over your cuts. If you start having to push harder than normal, that's a pretty reliable sign that your blades are dull or aren't equipped for the material you're cutting.

Practice on scrap material

Anyone who's ever received a bad haircut knows one universal truth: Once you've cut something, you can't uncut it. With that in mind, it's worth familiarizing yourself with your oscillating multi-tool before you start your DIY projects or home renovations.

Having the right tool for the job is important, but so is knowing how to use it properly. If you were teaching a child how to use a hammer for the first time, you'd probably give them a pile of nails and some scrap wood to practice on. That way, they can make mistakes and learn how to drive a nail in a low-stakes environment. You can and should take the same philosophy with any unfamiliar tool, including an oscillating multi-tool.

Grab any scrap materials you have lying around and start making cuts to see how your multi-tool works. Try out different blades and different materials to learn how the tool responds and make sure you're comfortable with the tool before you make the cuts that count.