12 Types Of Wire Nuts And Connectors (And What They're Used For)

We may receive a commission on purchases made from links.

Connecting wires have become a facet of everyday life, and humans have developed tons of ways to do it. Many of today's cables have connectors, like the humble USB-C cable, to make it incredibly easy for the end user to handle. For other applications, there are myriad wire connectors to get the job done. In your day to day life, you probably walk past a dozen of them every day, as most buildings have wire splicing and connecting in the walls where you can't even see them.

These wire connectors have dozens of applications depending on what you want to do, and they come with their own set of rules, an assortment of wire-specific tools, and other devices to help you connect one wire to another properly without starting a fire or shorting out whatever you're connecting. Most people have probably seen wire connectors in garages or junk drawers and may wonder what they are, what they do, and how they work. If you are one of those people, this is the article for you.

Below is a list of common wire connectors and their intended purposes. There are far more than 12 types of wire connectors out there, and some are so niche that they're only used for one thing, so we stuck to the most common ones. So, grab a nice pair of wire strippers and let's get started.

Twist-On Wire Connectors

By far the most common type of wire connector is the twist-on wire connector. These little guys are pretty simple to use and, as a homeowner who does their own repairs, I can tell you that the ease of use is a boon. These are also commonly referred to as wire nuts. Some believe it's because they look like a nut or because you can "screw in" wires like a nut. However, the wire nut is actually a trademarked name by Ideal Industries, sort of like how adhesive strips are often called Band-Aids.

In any case, these work pretty simply. You twist a couple of wires together and then stick them in the connector and then screw them in until they are hand-tight, just like a screw into a nut. The connector holds the two wires together and keeps the connection secured. You don't need to use any electrical tape, although some people do as a backup measure just in case.

These are used for general electrical applications all over. I've used a dozen of these working on my house's electrical wiring, but they're also used in commercial environments, and you'll even peep a few if you look at your automobile's wiring. The color and size also matter as well, denoting the amount of voltage and wire gauge size each one can handle.

Winged Twist-On Wire Connectors

The winged twist-on wire connector is an extremely close relative of the standard twist-on connector, and the two are often used interchangeably. In fact, they work almost identically, with the winged version having the extra plastic wings on the sides to grant the user additional leverage when connecting wire nuts. This can be helpful in some environments, especially in tighter spaces. However, the tradeoff is that winged wire nuts are physically larger, which means less can fit into their enclosed space.

In terms of pure mechanics, winged twist-on connectors work just like their non-winged brethren. You stick a couple of wires in there and "screw" them in. The mechanism inside of the nut twists the cables and holds them in place, allowing an uninterrupted flow of electricity. These connections are insulated from the space around them, minimizing the risk of damage. Theoretically, you don't need to pre-twist the wires before shoving them in a wire nut, but some people suggest that you do so anyway.

Much like regular twist-on connectors, the color and size denote how much capacity they have. Unfortunately, these aren't standardized across brands, but if you look at the packaging, you can usually tell what kinds of connectors you need for which applications. They are also used in the same spaces as traditional wire nuts, so they truly are interchangeable.

Crimp-on Wire Connectors

For more permanent applications, a crimp-on wire connector may be the way to go. These can be made out of metal or plastic, although even plastic ones have metal components, so they're all metal to some extent. For these, you'll need additional tools, including a wire stripper and a crimper tool, which are used to tighten the connector once the wires have been inserted. Some crimp-on connector kits come with one, which is good because most people probably don't buy those tools often.

The mechanism for crimp-on connectors is deceptively simple. The wires are inserted into the connector, and the crimper tool will crush the connector onto the wires. This creates a cold solder situation where the metal is functionally fused together. Whether or not crimp-on is superior to actual soldering is the subject of some debate, but in general, it's an easy way to make a near-permanent connection without breaking out the soldering iron and flux. In general, many agree that crimp-on works best for smaller wire where soldering would be pointlessly difficult.

Crimp-on connectors are mostly used in environments where the connection needs to be as close to permanent as possible. They're also useful in environments where standard wire nuts may not hold up, like industrial buildings with a lot of vibration. It is also a popular style in boats and automobiles.

Push-In Wire Connectors

Push-in connectors are some of the easiest wire connectors to use. They are fairly common, especially in countries like Japan, and they compete in mostly the same space as standard wire nuts. They offer an inexpensive, non-permanent way to connect wires together with an added bonus of having built-in support for more than two or three wires, with some having six, seven, or even eight slots in varying configurations. They are less common and popular in the U.S., with many opting for the good old-fashioned wire nuts instead.

These work very easily. You push the wire into the connector where it makes a connection internally. Once all of the wires are pushed in, electricity can flow through, and you can just leave them as they are. They do a require a bit more finesse as the wire actually has to fit into the connector, so making sure you have the proper size is paramount when choosing a push-in connector.

When they are used, they are general purpose electrical wiring components, so you'll most often see them in residential and commercial settings. They appear to be best for applications where the wires won't have much vibration or resistance, as too much tension can pull the wires out, especially if the wire is too small for the connector. They work well but use with caution.

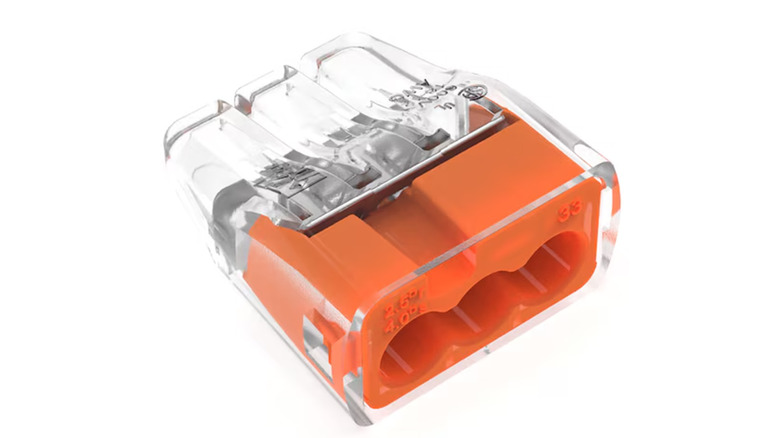

Lever Wire Connectors

The lever wire connector is the cousin of the push-in wire connector in that they both initially work the same way. These are often sold by a company called Wago, and are referred to by the brand name even if other companies make similar lever-style connectors. These have a better reputation among U.S. homeowners and electricians than regular push-in connectors thanks to the added benefit of the lever, and like their push-in counterparts, can support wiring setups with more than two wires.

In practice, these work very similarly to push-in connectors, but with an extra locking mechanism. Once you push the wire in and make the connection, you depress the lever, which then holds the wires in place. This mostly neutralizes the main complaint with standard push-in wire connectors in that the wires are much harder to pull out, and the connection is more stable. It does introduce moving parts which may fail eventually, but there aren't many examples of this happening.

Lever wire connectors are used in the same applications as wire nuts, winged nuts, and push-in connectors. That includes residential, commercial, and other uses like automobiles. Based on what people say, these are best used in situations where the connection may not be permanent, such as lighting setups, since wires can be easily removed by simply flipping the lever back up.

T-Tap Wire Connectors

T-tap wire connectors are one of the more unique options for wire nuts. These let you tap into an existing wire with a different wire without having to cut everything to shreds and reconnect it. It can be an elegant solution to what is typically an annoying problem where you don't need to cut the main wire, but you have to connect another wire to it along its line. These come in many sizes and shapes depending on the wire gauge and voltage needs.

They are surprisingly easy to use, all things considered. The clamp end attaches to the main wire, which bites into the wire insulation and makes a connection with the bare wire underneath. You then connect the second wire into the rear-end of the T-tap, thus connecting both wires together without having to cut or strip the main wire at all. You may also hear them referred to as quick splicers, T-splicers, or T-wire connectors since they make a T shape with the wires once they're connected, similar to the T-intersection on roads.

Many homeowners don't even know that tools like this exist, and that's okay. They are a niche use case. They seem to be used mostly for indoor wiring in residential and commercial spaces when someone needs to tap into a main line without severing it.

Heat Shrink wire connectors

The heat shrink wire connector is another common connector type that requires a separate tool to use. This time it's the heat gun, which has plenty of interesting uses. These don't tend to have the fire-and-forget feel of wire nuts or lever-style connectors where you can just connect them, tuck them away, and forget about them until you need to mess with them again. Heat shrink connectors are best used in permanent or semi-permanent applications where you don't want or need to mess with it again.

In terms of use, the heat shrink connector takes a little know-how to do correctly. You put the wires in and then use the heat gun to melt the connector around the wires. By melting the material, you create a secure connection that is also generally waterproof if it's done correctly. Most brands have an adhesive in the connector that melts onto the wire, helping to achieve a more watertight fit. In short, once it's applied, that thing isn't going anywhere unless you cut it off or heat it back up again.

Heat shrink connectors are usually used in harsher environments, as they can take hotter temperatures, wetter conditions, and environments with a lot of motion and vibration. Thus, they are perfect for automotive, marine, and industrial use. They're also commonly used in home entertainment setups.

Waterproof wire connectors

Waterproof wire connectors are another niche type of wire connector. You don't see these very often and they're usually not widely used. They are a variant of the winged twist-on wire nuts with the added inclusion of some extra waterproofing measures. If everything is done correctly, these can protect from water, water vapor, and other moist conditions, giving you a secure connection that won't fail at the first sprinkle of rain. The most common maker of these is DryConn, but other brands manufacture them as well.

For operation, they work almost identically to winged twist-on wire connectors. You twist two wires together, stick them in, and twist the connector until it's hand-tight, thus connecting the two wires. The big difference is that these are stuffed with a dielectric sealant of some sort, usually made of silicone, that covers the bare ends of the wire and protects them from moisture. These types of nuts also usually come with a rubberized end that repels some of the elements while a UV-resistant coating on the outside to resists sun damage.

Knowing all of that, it's pretty easy to see what these are used for, and that's for the outdoors. They should be strong enough to do wiring in a shed or outdoor lighting if needed. However, these do eventually fail over time, so make sure to inspect them regularly.

Al/Cu Connectors

The Al/Cu wire connector is a specialized type of connector used for buildings with mixed wiring. They are specifically made to connect aluminum wires and copper wires together. This is often a challenging task for DIY homeowners, especially if you don't know your chemistry. Aluminum is anodic to copper, which means when they're touching and electricity is present, aluminum will corrode copper over time. This means you have to be exceptionally careful when connecting the two, especially in homes where aluminum and copper wire may exist together and need to be connected.

The common maker of Al/Cu wire connectors is AlumiConn, which sells a 25-pack of these things for around $130. They are a lug-style connector that let you connect aluminum wire and copper wire in separate holes along with a healthy dose of silicone sealant that keeps the wires of corroding too much while they're connected. This is the easiest, albeit not the least expensive, method to connect copper and aluminum wire together.

In terms of use case, this one is fairly obvious. Any instance where you have to connect a copper wire to an aluminum wire is a good use for something like this. Lug connectors are also pretty well-known and reliable. The alternative is buying aluminum-rated things and avoiding the use of copper altogether, which can get tricky for DIY homeowners.

Underground wire connectors

Underground wire connectors are important because the ground is a dirty, dangerous place for just about anything if you leave it there long enough. It gets wet, cold, and even freezes on occasion. Such a harsh environment requires a special kind of wire connector, and the underground wire connector is the answer to that problem. It is a variant of the twist-on connector with some extra parts that allow it to live more safely underground. DryConn makes the most popular model we could find, but there are others on the market.

For the most popular version, the process is actually pretty easy. You twist the wires and screw on the cap like you would a normal twist-on connector. Once done, you insert it into a sized tube that is filled with dielectric silicone sealant. The container is then closed and buried. The sealant helps prevent water from shorting out the connection, and the container keeps dirt and debris from coming in. DryConn also boasts impact resistance, which also doesn't hurt for something buried underground.

There are other underground versions available, including a lug-style version that works mostly the same way with dielectric sealant and a plastic shell to keep dirt out. These are also generally UV-rated as well, so you can use this above ground if needed and, in some ways, may be better than standard waterproof connectors.

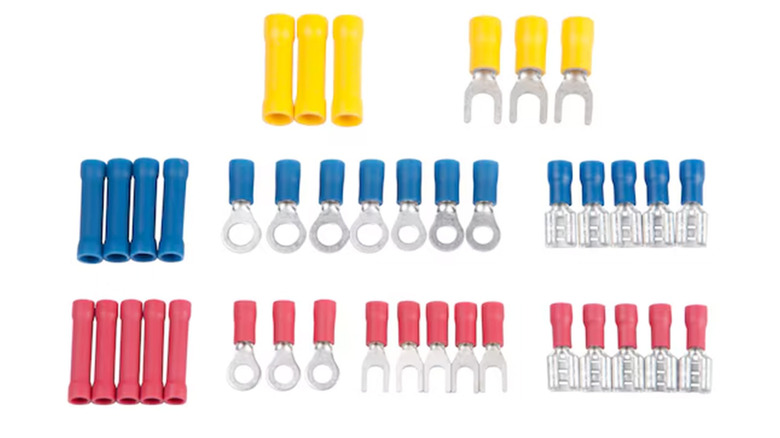

Terminal connectors

Terminal connectors work in a different way entirely. They allow you to terminate a cable into a different type of connection so that you can connect the wire to its final destination in an alternate way. These come in a variety of sizes, shapes, and variations, based on what the end user needs. Anyone who's ever connected or disconnected a car battery has seen these in action before. That wire you have to unscrew from the battery terminal is a terminal connector.

Terminal connectors are a subvariant of the crimp-on style of connector, and many use heat shrinking to connect the wire to its connector. Thus, to connect it, insert the wire and crimp it closed, either by heat or by crimping, depending on the connector type. Then, you're free to connect the end connection to whatever you want. The terminal shapes at the end are standardized, and include ring terminals, fork terminals, and blade terminals. Rest assured that if you need this type of connector, whatever you're plugging it into will be compatible with one of those three.

These are general-use wire connectors and are used in situations where you want to connect a wire to something that isn't another wire. For example, the fork terminals are often slipped under a screw before it's tightened to create a stable connection. Outside of car batteries, breaker boxes, and outlets, you won't see these terribly often.

Circuit Terminal Blocks

Circuit terminal blocks, often referred to as wire junction hubs, are arguably the best way to connect a lot of wires at once. These come in a variety of shapes and sizes and are suitable for a wide variety of jobs. They are often compared to Lego blocks thanks to their utilitarian appearance, and they aren't terribly common for DIY homeowners. The good news is that in the rare event where you need one of these, they are abundantly available, relatively cheap, and generally easy to use.

To use one, you loosen one of the screws, snake in a wire, and then tighten the screw again to hold the wire into place. Repeat as necessary for the number of wires you need, and all of them will be connected together. Anyone who's ever replaced a light switch has probably dealt with this mechanism before and while it is simple to understand, execution may be more difficult depending on wire length and gauge. I always have problems with the neutral, personally.

In any case, you usually see these in residential, commercial, and industrial buildings, usually in breaker boxes, junction boxes, or as part of something like the aforementioned light switch. It's one of those things where DIY homeowners won't interact with them often, but electricians certainly do, so their commonality depends on your job description.