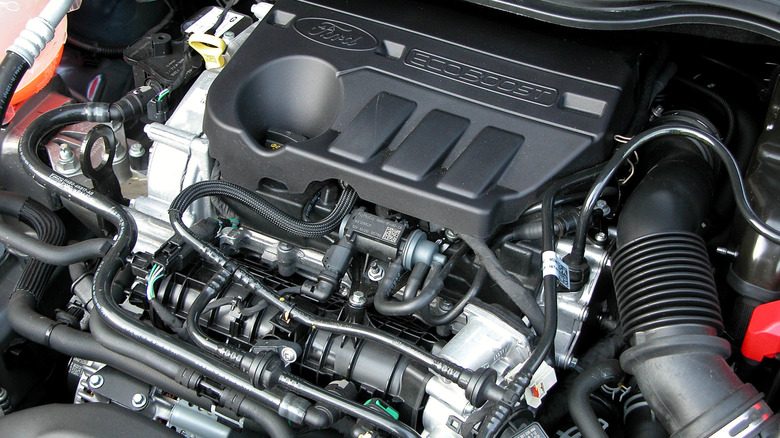

How Ford EcoBoost Engines Work: A Complete Guide

In case you missed it, the automotive industry has been on a steady trajectory of internal combustion engine (ICE) downsizing for years. Battery-powered electric vehicles may capture most of the limelight these days, but the old ICE isn't extinct yet. However, to ensure these gas-powered mills remain capable of keeping up with ever-tightening emissions regulations, automakers have leaned hard into the world of turbocharging.

Turbocharged engines are nothing new, as defunct carmaker Oldsmobile debuted the first mass-produced car with a turbocharger back in 1962 on the F-85 Cutlass Coupe. Today, you can find this forced induction approach in the lineup of nearly every major auto manufacturer. However, few have managed to market turbocharging as effectively as Ford. When the Detroit carmaker rolled out its modern lineup of boosted engines 15 years ago, it gave the powertrain a name: EcoBoost.

Since then, the EcoBoost engine has expanded throughout Ford's lineup with three-, four-, and six-cylinder versions. There is more to how the EcoBoost engine works beyond turbocharging, but the overarching idea from Ford was to build a powertrain with better performance and fuel efficiency than the larger, naturally aspirated engines common to icons like the Mustang and F-150.

What is Ford EcoBoost

EcoBoost is Ford's brand name for its line of turbocharged engines. It accounts for Eco as in economical and Boost as in turbocharging. Ford created the EcoBoost engine to improve power and fuel economy versus its long-running portfolio of naturally aspirated engines. To do so, the automaker blended three key components into its EcoBoost engines — turbocharging, direct fuel injection (DFI), and variable camshaft timing (VCT).

As with turbocharging, DFI and VCT are widely used across the auto industry, but credit to Ford for bundling the three technologies into a new brand dubbed EcoBoost. Introduced in 2009, the EcoBoost engine was a cornerstone of Ford's efforts to meet federally-mandated fuel efficiency standards that were set at 54.5 miles per gallon by 2025. To do so, EcoBoost engines were intended to be 20% more fuel efficient than comparable naturally aspirated mills, while reducing emissions by 12%.

For 2011, Ford debuted an EcoBoost-powered Explorer that was the most fuel-efficient seven-passenger SUV on the market at the time. Given the pushback from traditionalists on reducing cylinder counts and adding forced induction, this was considered a vindication for Ford that it was on the right path. Seeking the ability to deploy EcoBoost powertrains across a wide range of vehicles from small cars to large trucks, Ford worked to unleash these new engines across its lineup.

EcoBoost engines: turbocharging

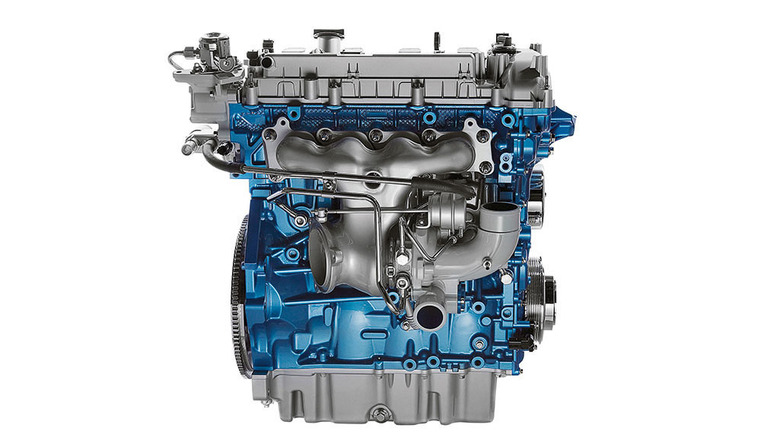

The basic concept of turbocharging a car engine is delivering a compressed charge of air into the combustion chamber to increase efficiency without increasing cylinder size or displacement. As with any turbocharger, Ford's EcoBoost design captures energy from the engine exhaust, that would otherwise be wasted, to rotate a turbine within the turbo. As the exhaust gases flow over this turbine, it spins a shaft that is coupled with a compressor on the other side of the turbocharger.

As intake air flows into the compressor, it is pressurized or compressed, a process that adds heat. So, the EcoBoost engine sends the compressed air into a charge air cooler that works to bring the temperature down, as cool air is denser than hot air, meaning it combusts more efficiently. Finally, the air is routed through the throttle body to the intake manifold and through the intake valves to gather under pressure within the combustion chamber.

Post-combustion, exhaust gas is sent to the dual-chamber exhaust manifold found in Ford's EcoBoost engines. It maintains an air gap between the engine compartment and exhaust, which in turn keeps the exhaust hot. That allows for more efficient turbocharger operation, which spins the turbine up to 200,000 rpm while keeping the engine compartment cooler. In the case of three- and four-cylinder Ford EcoBoost engines, there is a single turbocharger at work, while V6 models have two, one for each bank of cylinders.

EcoBoost engines: direct fuel injection

Ford uses direct fuel injection (DFI) in its EcoBoost engines as a way to improve efficiency while generating more power. An engine with port injection sprays fuel into the intake ports where it mixes with air prior to introduction to the cylinders. DFI delivers a precise amount of gas, in a fine mist, directly into the combustion chamber where it mixes with compressed air from the turbocharger to do the internal combustion dance.

The way this works in an EcoBoost engine starts with a low-pressure fuel pump sending fuel to the engine. From here, the fuel is run through a mechanically actuated high-pressure pump driven by a four-sided camshaft lobe. Next, the gas gets sent into a stainless-steel fuel rail at pressures ranging from 65 to 2,150 psi before it finally passes into the fuel injectors, which spray the pressurized gas directly into the combustion chambers.

Along with carefully regulating fuel quantity based on demand, this high-pressure fuel system used in EcoBoost engines cools the charge. That allows for higher compression ratios, which brings the efficiency and power generation gains, versus port injection, full circle. Though DFI is highly regarded for its benefits over port injection, one potential downside is carbon buildup on the intake valves, which we'll look at below.

EcoBoost engines: Ti-VCT

Ti-VCT stands for twin independent-variable camshaft timing and is a key aspect of making Ford's EcoBoost engines work the way they do. Like variable valve timing, Ti-VCT optimizes engine valve timing to enable higher torque when required and minimizes fuel consumption at lower performance ranges. With variable camshaft timing, the timing of when the camshaft opens or closes the intake and exhaust valves change depending on demand.

Along with better fuel economy and increased low-end torque versus larger naturally aspirated engines, Ford's Ti-VCT system reduces exhaust emissions and allows for the elimination of the exhaust gas recirculation valve typically found in an ICE. To do so, the Ti-VCT system controls the overlap between the opening of the intake valve and closing of the exhaust valve. A small amount of gas gets pulled into a given cylinder during the piston's intake stroke.

This principle applies to most Ford EcoBoost engines with the exception of the 3.5L V6. In that application, an intake phase shifting system is used to control only the intake camshaft. This is perhaps only relevant to a mechanic working on one of these EcoBoost engines, but considering how popular the F-150 is, it doesn't hurt to understand the differences between variants and how they may impact future service needs.

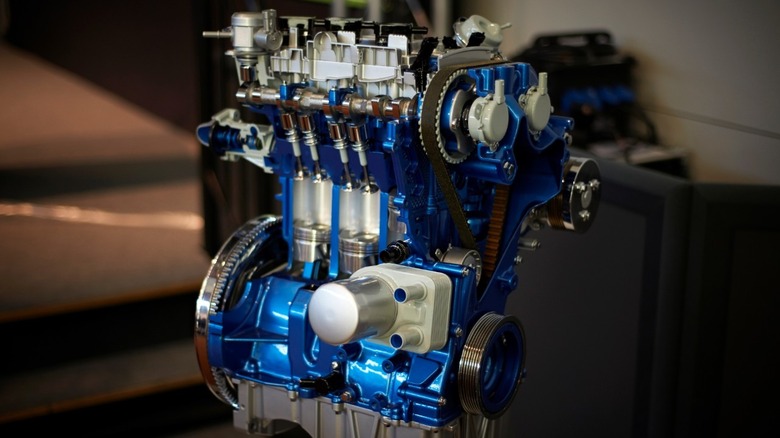

Three-cylinder EcoBoost engines

Ford currently sells the EcoBoost engine in three-, four-, or six-cylinder configurations. All have merits, but arguably, the three-cylinder mill is the most appropriate application of the EcoBoost ethos. If the goal is to deliver superior power and efficiency from a smaller engine, it's hard to beat a tiny inline-three cylinder for the best-use case. Though used worldwide in a range of displacements, the 1.0-liter Fox inline-three EcoBoost found in the short-lived North American EcoSport is of particular interest.

That's because the 1.0-liter Fox engine in these subcompact crossovers made 123 horsepower per liter. In the world of specific output comparison, that's worth writing home about. In fact, it is near what the Honda S2000 produced with what SlashGear named one of the 10 most impressive naturally aspirated engines ever made. Nobody is going to confuse an EcoSport with an S2000, but there's no denying this little SUV is a prime case study of going the EcoBoost route.

Unfortunately, the EcoSport was discontinued in the U.S. as of 2022, after just a few years of production. Reasons cited include a low-rent interior and an underpowered engine. Without a doubt, a 123-hp three-cylinder engine is a tough sell for Americans accustomed to at least four cylinders, if not double that. However, a 29 highway and 27 city mph rating against the naturally aspirated inline-four that was also available with the EcoSport, meant the EcoBoost engine was up to the fuel efficiency task.

Four-cylinder EcoBoost engines

Currently, the only three-cylinder EcoBoost-powered Fords available for sale in the U.S. are the Bronco Sport and Escape, which feature the 1.5-liter Dragon model. However, there are a host of four-cylinder versions currently available, like the 2.0-liter unit offered in the Escape, Bronco Sport, and Maverick or the more powerful 2.3-liter EcoBoost four-cylinder found in the Ranger, Explorer, Bronco, and Mustang.

Though it has been discontinued in the U.S, one of the more notable four-cylinder EcoBoost engines Ford made was the 1.6-liter Sigma unit found in the Fiesta ST hot hatch. It had an aluminum block and head versus the three-cylinder versions that only make use of alloy construction for the top half. More interesting, from an enthusiast perspective, was the hotrod Fiesta's performance.

Making 197 hp at 6,000 rpm and 202 lb-ft of torque at 4,200 rpm, this EcoBoost only had to move 2,734 pounds of mass. Per a 2017 Car and Driver review, "The turbocharged 1.6-liter inline-four has precisely the perfect amount of beans. Its 197 horsepower adds a Fiesta-sized drizzle of accelerative thrills without overwhelming the front-drive ST's drivability." So, along with fuel efficiency in examples like the EcoSport, Ford's EcoBoost can clearly hit the performance targets as intended.

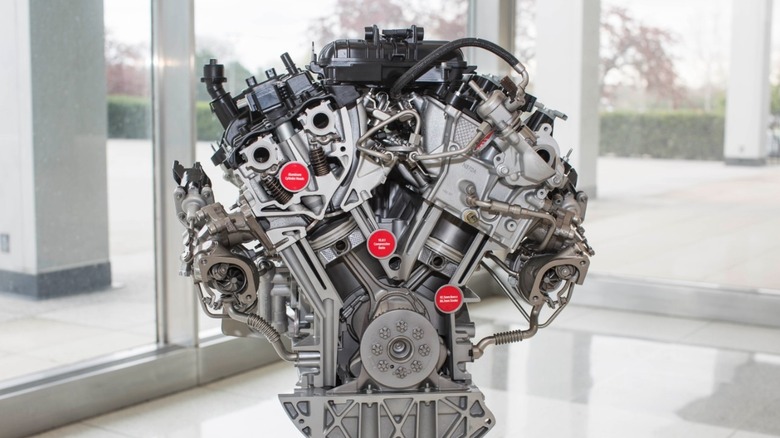

Six-cylinder EcoBoost engines

As you might expect, the V6 version of Ford's EcoBoost is put to use when a higher level of performance is required. To get there, the largest displacement EcoBoost mills work with two turbochargers instead of the single snail of three- and four-cylinder variants. With the 2.7-liter setup offered in the Bronco Badlands, there is 330 horsepower on tap. Step up to the 3.0-liter EcoBoost V6 in the Explorer ST and that figure jumps to 400.

The high-output 3.5-liter twin-turbo V6 Ford puts in the F-150 Raptor starts to hit serious output numbers like 450 hp and 510 lb-ft of torque, but perhaps the most impressive application of Ford's EcoBoost engine is the 3.5-liter unit found in the GT supercar. Running on 93 octane, this mid-mounted EcoBoost is rated for 647 hp at 6,250 rpm and 550 lb-ft of torque at 5,900 rpm, which is capable of launching the 2017 Ford GT from 0 to 60 mph in under 3 seconds.

Ford says its street-legal race car can reach a top speed of 216 mph, but in this rarified air of six-figure automotive fantasy, the bigger news may have been Ford's decision to go with a V6 over a V8. However, as we noted in a behind-the-wheel drive of the Blue Oval's halo car, the traditionalist mentality that a V6 is somehow lesser is moot because, "The GT doesn't roar like a V8 might, it screams like an enraged banshee," and it boasts "...acceleration like a runaway cruise missile."

EcoBoost vs. PowerBoost

Ford sells EcoBoost engines alongside something it calls PowerBoost. Currently only offered on the F-150, the PowerBoost setup starts with a 3.5-liter EcoBoost V6 and blends in a battery-powered 44 hp electric motor to create a traditional hybrid powertrain. The Power part of the name could be attributed to the relatively huge output figures of 430 hp and 570 lb-ft of torque, or it might be due to the exportable power these F-150s have on hand.

Ford calls it ProPower Onboard (PPO), which is a marketing term for a battery-powered generator capable of up to 7.2 kilowatts of juice. For buyers, that means there is a panel in the cargo bed with multiple household-style 120-volt outlets and a 240-volt receptacle on certain models. PPO can be used to power just about anything you can think of, like speakers and a TV for a mobile movie theater or a circular saw and air compressor on the jobsite.

Though Ford sells a hybrid-powered Maverick compact pickup truck and previously offered an Explorer hybrid, both of these vehicles utilize a naturally aspirated combustion engine, so they are neither EcoBoost nor PowerBoost vehicles. That's a shame as the PowerBoost configuration in the F-150 delivers 30 more hp and 70 more lb-ft of torque than the non-hybrid EcoBoost setup and is far more fuel efficient with a 7 mpg increase in city driving and 5 more mpg combined.

Common EcoBoost engine issues

Though powerful and relatively efficient compared to its naturally aspirated, big-displacement brethren, the Ford EcoBoost engine is not without its issues. One common sign of trouble is turbocharger noise. Leaks on the on the low-pressure side of the turbo can present as a whistling sound, while high-pressure leaks often hiss. Another cause of this issue is a stuck turbocharger bypass valve, which can result in notable noise during sudden deceleration.

Carbon buildup is the more frequently cited issue with the EcoBoost, which is a side effect of the direct fuel injection design. On the exhaust stroke, as the exhaust valve opens, the intake valve opens to allow in a small amount of forced air. The idea is to help evacuate exhaust gases with fresh air, but during the overlap, some of those combustion gases can get around the intake valve and cause carbon buildup on the back side.

One reason for this is the design of the DFI system, which sprays fuel directly into the combustion chamber versus onto the intake valve, where it would simultaneously clean off the valve. This buildup may disturb airflow. A good way to combat it is by following Ford's maintenance schedule, including regular engine oil changes with the correct oil type.

EcoBoost engine efficiency

To evaluate Ford's claim that its EcoBoost family of engines offers more power and increased efficiency over similar naturally aspirated, larger-displacement engines, we've pulled together a few key vehicles. The 2021 F-150 offered both a free-breathing 5.0-liter V8 and a 3.5-liter PowerBoost V6. The V8 was rated for 400 hp and 410 lb-ft of torque versus the V6 that made 400 horsepower and 500 lb-ft of torque.

For rear-wheel drive F-150s, both engines delivered a 24 mpg highway rating and a 20 mpg combined rating, while the city driving figure was 1 mpg higher with the EcoBoost mill. Though the fuel efficiency delta is not eye-opening, it's more impressive considering the 90 extra lb-ft of torque versus the V8. Looking at the 2021 Mustang, which offered both a 2.3-liter EcoBoost inline four and a naturally aspirated 5.0-liter V8, the fuel consumption comparison is more pronounced.

With a six-speed manual, the V8 delivered 15 mpg city, 24 mpg highway, and 18 mpg combined versus 21, 29, and 24 mpg, respectively, for the four-cylinder-powered Mustang. Granted, these more efficient models made 310 hp and 350 lb-ft of torque versus 460 hp and 420 lb-ft of torque for the V8. However, considering the EcoBoost powertrain has half the cylinder count of the big V8, the case for going the forced induction route is compelling.