9 Ways To Maintain Your Generator For Emergencies

Backup generators are a lot like old friends in that you forget about them until you need a favor. And when there's an emergency, you expect them to show up instantly, no questions asked. But generators are machines, and that kind of reliability doesn't happen on its own. Simply refueling your generator isn't enough to keep it in working condition. It requires regular inspections and maintenance. How often you use the generator is irrelevant, what's relevant is that the unit is able to perform when it actually matters.

You don't need to be an expert or spend hours taking care of your generator. But you do need to be informed and to get involved. That means getting your hands dirty with changing the oil, replacing spark plugs, and battery maintenance. And the only way to do this is to go the extra mile. With that said, here are nine ways to maintain your generator for emergencies.

Install and use a manual transfer switch

One common and costly mistake generator owners make is directly connecting the generator to a home's electrical panel. Straight out of the box, most generators come with the unit itself, a user manual, a basic tool kit, and battery accessories, if it is an electric start model. Based on this alone, it's easy to assume that it's okay to plug the generator in directly.

Directly plugging in a generator leads to backfeeding, which happens when electricity flows backward from your generator to the utility line, and can cause an electrical safety hazard. This is where a transfer switch comes in. A transfer switch is a permanent switch attached to your power box that allows for a seamless transfer of the electric load between your two sources: the main power grid and your backup generator.

Transfer switches come in different types, and your choice should depend on your generator unit. It can be manual or automatic and have an open, closed, or delayed transition. Choose based on your generator's specs and how you plan to use it.

Follow the recommended servicing schedule

User manuals are boring, no question. They're incredibly technical and, in most cases, bulky, so it makes sense that you'd want to skip them. But when it comes to preserving the lifespan of your generator, the user manual is the most reliable guide.

The average user manual provides general tips for maintenance, naming routine tasks, like changing oil, air filters, and spark plugs. Some brands, like Cummins, include a detailed maintenance table for you to track how often you're performing these tasks. This routine maintenance is important for noticing faults and addressing them before they can completely damage your generator.

While routine maintenance is something you can perform yourself, some tasks are required to be performed by a licensed professional. This is because without formal education, you're more likely to do more harm than good. Most user manuals specify that some parts of the maintenance should be performed by professionals at least once a year.

Depending on the manufacturer, some brands recommend that you seek the services of a professional, preferably one who is licensed and works with the manufacturer of your generator unit. Their responsibilities often involve updating hardware, inspecting the engine, and testing the batteries. They can also make sure that your machine and installation are on par with standard safety practices.

Run the generator with load at least once monthly

Even if power outages are rare, it's important to exercise your generator regularly. Generators are not built to sit idle for long periods. Without regular usage and testing, they start to develop internal issues, making them useless in an actual emergency.

Exercising means running your generator for a short period under minimal or medium load. This gives the unit time to warm up, circulate the oil, and get rid of moisture that could have accumulated within the system. When run long enough, it also allows you, or a technician, to identify any issues like fuel line blockage, engine malfunctions, leaks, or inconsistent power output.

Manufacturers typically recommend running the unit for 12 to 30 minutes at a time, at 50% of your total load. This lets you assess how well the generator is working and whether it can adequately power your appliances. Leaving the generator completely idle can lead to system issues like clogged filters, corroded components, and possibly long-term or permanent damage.

Prep for cold weather

Cold weather can have a negative impact on your generator's performance. The freezing temperature causes the engine oil to thicken, slows battery performance, and ultimately delays ignition. It's even worse if the generator is left completely idle during this season, then it might not start at all.

This is why you need to prep your generator around the same time you start shopping for winter boots. Start by checking the oil. Your job here is to make sure that the oil hasn't thickened due to the cold. If it's been sitting in the unit unused for a while, drain the old oil and replace it. You can do this with the oil you already use or opt for a winter grade option, which is specially formulated for lower temperatures.

Next, check the batteries. If your generator uses a battery, clean the terminals and charge fully. The cold can make batteries drain much faster, so you want to make sure to test their voltage and capacity.

Finally, check the fuel and inspect the exterior of your generator. Most importantly, make sure that your generator isn't exposed to the snow, rain, or excessive wind. Generators shouldn't get wet, and running the unit in the rain can lead to electrical hazards. You can invest in snow covers to prevent the exposed parts of your generator from freezing.

To make this even easier, consider investing in a cold-weather kit, which often includes battery heaters, oil warmers, and block heaters. You can get this from some manufacturers like Generac, or you can build your own.

Store outside in a safe, dry, and well-ventilated area

Generators don't belong indoors. Storing indoors in tight or enclosed spaces, like your basement or garage, poses a safety hazard and risks exposure to deadly carbon monoxide emissions. Carbon monoxide is a colorless and odorless gas, so it's not enough to crack the window open either.

A generator should always be stored outdoors in a dry and well-ventilated area. While you can opt to store your generator in an outdoor shed, it shouldn't be in a cramped or right corner. You need to make sure that there is at least 3 feet between the generator and any walls, fences, shrubs, or decorations. That way, there is proper airflow around the unit to prevent overheating and safely dissipate the toxic gas fumes.

Regardless of what season it is, the unit should be protected from direct exposure to natural elements. While a little rain isn't going to completely shut down your generator, the unit is not waterproof. Similarly, direct sunlight or high humidity can cause the system to short-circuit and accelerate wear on internal components. Manufacturers like Honda recommend storing generator units under canopies or ventilated covers to keep them dry without trapping fumes.

Use fresh fuel and change regularly

Generators can last up to 3 decades with proper maintenance and care. Fuel, on the other hand, can't stay around nearly that long. Gasoline and diesel fuels are hydrocarbons that degrade over time. So, exposure to oxygen, extreme temperatures, and moisture can reduce the quality of the fuel. Bad fuel means rusted tanks, clogged filters, and damaged injectors, which are bad news for your generator unit.

Luckily, diesel fuel can last 12 months or more when stored and treated. Proper storage involves keeping the fuel in a dry, airtight container away from direct sunlight and heat sources. Even with good storage options, it's better to buy only what you'll need for a few months.

The quality of your fuel also depends on where you get it. Make sure you're buying from a reputable fuel station. But be sure to keep in mind that the fuel may have been sitting in commercial reserves for some time before you purchase it. Ultimately, it's a good idea to watch what goes into your generator because it's only as good as the fuel that powers it. Old and contaminated fuel can cause major problems that lead to costly repairs.

Test and maintain the battery monthly

A generator that refuses to start doesn't necessarily have a bad engine. In some cases, it's the battery. Weak or dead batteries are one of the most common reasons for a generator not starting.

Batteries typically lose charge over time, especially if they've been sitting idle. This is why it's essential to test your battery at least once a month, typically on the same day as the monthly load test. Test the conditions of the battery with a voltmeter to check its charge. If it's around 12.6 volts or higher when fully charged, then you have nothing to worry about. Any lower, then you may want to pay more attention. It's also important to inspect the physical appearance of the generator. Check the terminals for corrosion, and look out for any swelling or cracks in the casing. All are signs of battery aging.

Aside from testing, you can maintain your batteries by making sure that the terminals stay clean and securely connected. If you're concerned about the corrosion of the batteries, apply some anti-corrosion gel as part of your routine maintenance.

Drain the carburetor if storing for a while

In a season with no emergencies, it's okay to forget about your generator. What is not okay is leaving fuel sitting around in the unit for months. Fuel left inside the generator can cause long-term damage to the unit.

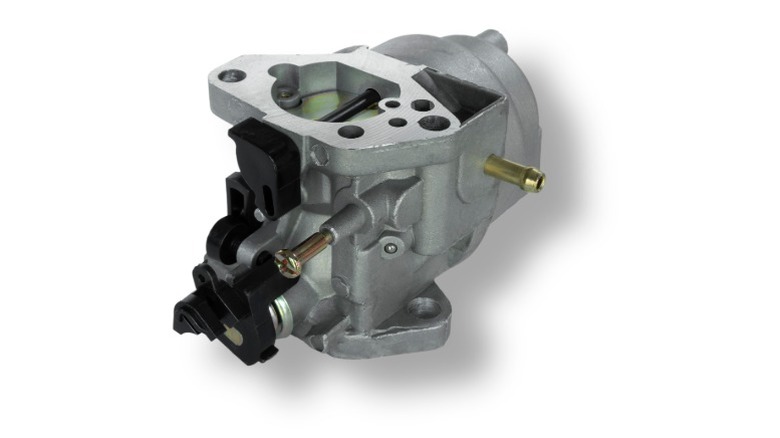

Fuel evaporates over time, and when it does, it creates a sticky residue that clogs up the carburetor's jets and fuel passages. When this happens, it's likely that your generator won't start in the next power outage. To avoid this, it's advisable to drain the carburetor before you store the unit away for a long time.

To start, turn off the fuel valve and locate the carburetor above the air filter housing, in most units. Once you've found it, get a gasoline storage container and loosen the drain screw to let the fuel empty out completely. Alternatively, if you won't be storing it away that long, add a fuel stabilizer and run the generator for a couple of minutes to let the fuel circulate.

Simulate a power outage at least once a year

Don't wait for a real emergency before you test your backup plan. One way to truly prepare is to simulate a power outage at least once yearly. This way, you can be sure that your generator can deliver under realistic outage conditions. Unlike running a routine exercise, the drill should mimic a real outage, both in duration and power usage. That means running the generator under a realistic load, with the same appliances you'd typically need powered during an emergency. This can include your fridge, lights, TV, and internet router.

Also, such simulations should run for an extended period, not just 30 minutes at full load. Switch off your main power source and let the generator run for a longer time, between 4 and 12 hours. This is ideal since many portable generators are designed to run for about 6 to 18 hours on a single tank.

Performing this annual drill means you'll be able to spot any issues you might have missed when you did the routine exercise. Things like tripping circuits or unstable power delivery. Also, if you added any new appliances after getting the generator, you'll be able to see how well the generator can handle the extra load.