OHV Vs. OHC: What's The Difference Between These Engine Designs?

OHV stands for overhead valve, and these types of powerplants can also be called pushrod engines. OHV engines have the intake and exhaust valves located above the camshaft, which is in the engine block and driven by the crankshaft. The valves are actuated by pushrods that run from the camshaft lobes to rocker arms in the cylinder head, which enable the valves to open and close. Most OHV engines have two valves per cylinder.

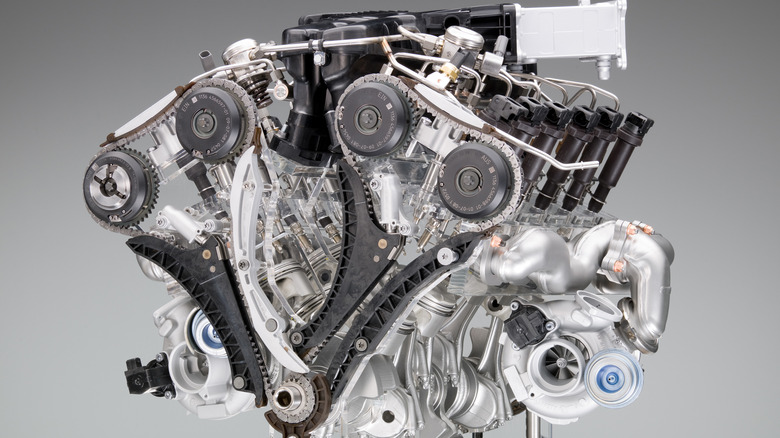

In contrast, OHC stands for overhead camshafts, and these types of engines can be found with a single camshaft (SOHC) or double camshafts (DOHC). While an SOHC engine typically has two valves per cylinder, a DOHC engine can have four valves per cylinder. Camshafts are located atop the cylinder heads and control the opening and closing of the valves. A timing chain or belt connects the camshafts to the engine's crankshaft. Ultimately, the difference between an OHV and an OHC engine design comes down to two things: the valve operation and the placement of the camshaft. Each type has its strengths and weaknesses.

What are the pros and cons of OHV and OHC engines?

OHV engines have a number of benefits. Compared to OHC engines, they are more compact in size due to the camshafts being inside the engine. They also cost less to produce and are more durable with lower maintenance costs. These pushrod mills powered classic muscle cars of the 1960s and 1970s, allowing quick acceleration due to their high torque levels at low RPMs. The Oldsmobile Rocket 88, for example, used an OHV V8 engine.

However, OHV engines are less reliable than OHC engines due to their numerous moving parts and because the pushrods may begin to flex over time. As higher RPMs are reached, these engines get trickier to control and have lower performance. For instance, variable valve timing is not possible on an OHV engine, while it can be done on a DOHC.

In contrast, OHC engines can reach higher RPMs and have greater control when they do. There is also more space created between the intake and exhaust valves in their design, which makes for better airflow. However, OHC engines have a larger overall head size, higher manufacturing costs, and greater complexity. They also require timing belts or chains, which may experience wear and need to be replaced. SOHC engines are less expensive to produce and maintain than their DOHC siblings, but they are unable to achieve the power, performance, and fuel efficiency that come with DOHC engines. Ford's Coyote 48, one of the best of all time, is a 32-valve DOHC engine.