Which Cummins Block Is Most Prone To Cracking?

We may receive a commission on purchases made from links.

Cummins diesel engines are highly regarded as being tough and reliable. However, the 5.9L Cummins 24-valve engines produced from 1999 to 2002 used engine blocks that are prone to cracking. While any cast iron or aluminum engine block can crack under adverse conditions, the Cummins "53 block" used in those engines is the most prone to cracking. Some 12-valve 5.9 Cummins engines also used a 53 block, but those earlier model blocks are less prone to cracking, according to MotorTrend.

The best way to prevent the 53-block cracking issue is to avoid owning one. While it's easy enough to rule out the purchase of 1999 to 2002 24-valve 5.9 Cummins-powered Ram trucks, it's possible that another model year could be blessed with the doomed engine block through an engine swap. The only foolproof way to avoid any chance of winding up with a 53-block Cummins in your driveway is to check the engine block for the 53 casting mark. The raised casting number is most often located on the driver's side, near the front of the block, but it can also be found on the passenger side. Exploring with your phone camera or another small device is often the best way to find it.

If you already have a 53-block Cummins, or you're considering the purchase of one for whatever reason, you should keep an eye out for signs and symptoms of a cracked engine block. The most common sign of the 53-block crack is coolant leaking from the side of the block.

What causes Cummins 53-block cracking

While not every 53-block Cummins will crack and develop a coolant leak, it's a common enough problem that it creates a substantial amount of concern among those who own them or are considering buying a 5.9 Cummins-powered 1999 to 2002 Dodge pickup truck. To be clear, online resources, such as the Cummins Forum, have more posts touting the longevity of the 24-valve 5.9 Cummins with 53 blocks than horror stories, although there are some examples of failures.

The issue with the 24-valve 5.9 Cummins 53 blocks is a weak spot in the original engine block casting on the passenger side, just below the freeze-plug holes. Over time, as the blocks are subject to vibrations, internal pressures, and external rust, some of the weaker engine blocks will develop cracks in the water jacket designed to cool them.

Like any other engine block, they can fail if subjected to sub-freezing temperatures, allowed to rust internally from improper maintenance, or overheated if the cooling system isn't up to par. However, it doesn't seem to matter how well the afflicted 53 blocks are maintained, eventually they'll crack and leak coolant, it's just a matter of time.

Is it possible to fix a cracked Cummins 53 block?

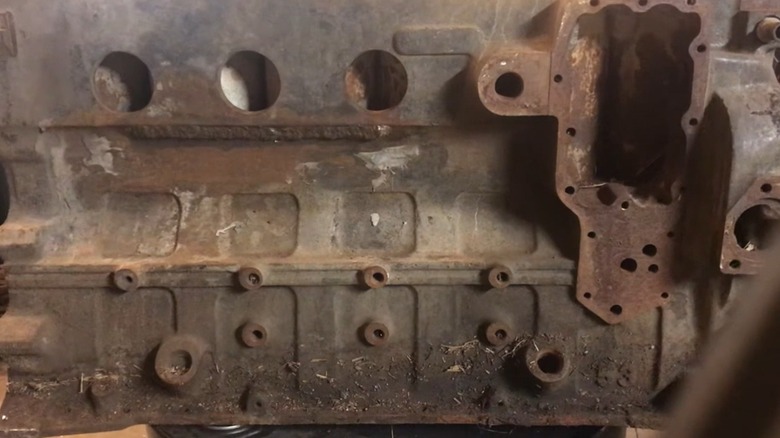

The options for repairing a cracked Cummins engine block are limited, and most results range from a temporary fix that will likely only get you off the side of the road to a temporary fix that could last a few months. The easiest and most temporary of fixes (shown above) is to cover the cracked area with an additional metal plate filled in with a two-part epoxy such as J-B Weld KwikWeld Steel Reinforced Epoxy.

More permanent temporary fixes include various welding techniques. However, these will likely require the involvement of a professional welder. If you're the DIY welding type, it's possible to get some additional life from your cracked Cummins block using a good Harbor Freight welder. While we're not advising you to strike an arc on your Cummins, if it's already cracked and unusable, there isn't much to lose by trying. The problem is that just welding the cracked area doesn't eliminate the weak spot in the casting.

The most reliable long-term fix for the 53-block Cummins is to replace it with a non-53-block model, such as a 6.7 Cummins crate engine. It's also possible to buy a replacement engine from a junkyard for the engine swap and sell the 53-block Cummins to offset a portion of the cost.