Woodworking Clamps: A Complete Guide To Each Type (And What They're Used For)

We may receive a commission on purchases made from links.

These days, the craft of woodworking is more accessible than ever. Cutting joinery elements can be made simple with all manner of power and hand tools specially designed for woodworking, and purpose-built jigs can making getting precise, repeatable cuts on many wood varieties possible without too much specialized equipment. There are certainly a cadre of traditionalists out there, but no matter where you fall on the spectrum, woodworking as a craft offers an open mind and a welcoming hand. And if you want your early career woodworking projects to extend beyond a first workbench and an abundance of boxes, there are also a great many YouTube channels online today focusing on woodworking as an art form. These creators — both in the physical and digital sense — demystify the craft, making it more accessible to anyone who might be fostering a passion for making things.

Experienced builders and new arrivals alike might entertain just a bit of curiosity surrounding some of the gear these YouTubers bring out during their projects, though — sometimes it can get a bit excessive. The clamps, in particular, often come in a volume and variety that can get overwhelming. If you find yourself confused by the wealth of unique designs, you're not alone. Clamps come in a wide range of styles, each aimed at delivering precise gripping power in specific ways. This guide will help make sense of the different types available, as well as the use case for each one.

F-clamps

The F-clamp is perhaps the standard clamping tool that most people will be familiar with. It's useful across a range of needs in the workshop, covering everything from glue ups to securing your workpiece for drilling holes, planing board faces, and more. The F-clamp generally features a moderate to small work holding dimension (maxing out at around 3 feet in the largest models). In order to use this tool, you unscrew the clamping segment itself and reposition its mobile arm until the opening is wide enough to maneuver the tool around the piece you're trying to grip. Then, tightening the clamp by screwing the grip handle back into place will bring the mobile jaw back into position and press the target object against the stationary end of the clamp.

The F-clamp features relatively deep dimensions between the gripping component and the bar that holds the tool together on its back end. This makes it ideal for many general-purpose clamping needs in the workshop and beyond. It's simple layout allows you to pivot it around things to facilitate placing multiple clamps in quick succession or as a means to create something of a frame-like structure around the workpieces you're gluing together. This framing can be important from using other clamping devices in concert with your F-clamps.

Clutch clamps

The clutch clamp has almost the same design as the F-clamp, with one important addition. Clutch clamps feature a trigger near the base of the mobile component. This allows you to quickly reposition the movable jaw and then lock it back in place. In addition to increased mobility and ease of use, this clutch feature also makes it easier to remove this type of clamp from a workpiece when you're done with it over the similarly built F-clamp. Instead of unscrewing the clamping component while under tension, hitting the clutch lever immediately takes the pressure off and allows you to quickly move the clamp away with less hassle.

If you're looking to upgrade gripping functionality in the workshop, opting for clutch clamps over traditional F-clamps can be a great way to do it. It's worth noting though, both clutch clamps and F-clamps have a greater tendency to bow when placed under extreme tension than some other clamp varieties. This means that you may want to use another type of clamp for long-term high-tension tasks. Going overboard with F-style or clutch clamps can also help take the pressure off each individual addition to the gripping array, and pairing these clamps up with other, sturdy solutions when performing a glue up can also be a valuable approach.

C-clamps

C-clamps are arguably one of the most iconic work holding solutions available to woodworkers and others who need to clamp material in the workshop. Like F-clamps, C-clamps are named after the shape of their gripping design. Similarly, C-clamps also look and perform in a very similar fashion to F-clamps. The C-clamp doesn't feature an adjustable segment in its build, however. That lack of extendable functionality also means C-clamps are often smaller in stature than most other clamping solutions.

The C-clamp also tends to have a much shallower throat than others, F-clamps included. This means that you can't position a C-clamp nearly as far in toward the center of a component you are trying to grip as some other solutions in this realm. Even so, the C-clamp is a quintessential work holding option that can be a valuable addition to perform basic grip requirements in the garage or general purpose workshop.

Bar, pipe, and sash clamps

These clamps all feature a similar layout. Bar and pipe clamps are essentially elongated clamping tools that run along the distance of a hardened metal bar (or pipe). They feature a threaded screw to tighten down the clamp's faces or to open the jaws. Pipe clamps in particular often come as a set of clamping heads that you can set on your own pipe. This is a particularly useful functionality, giving users the ability to customize the length of their gripping asset for each unique job that they might see.

A sash clamp is another solution that operates in a similar fashion. Sash clamps feature a flat bar and fixed jaw. These are often some of the longest clamps woodworkers will have in their collection, delivering the greatest versatility in large project parameters. Even with this expanded reach, sash clamps (as well as bar and pipe varieties) aren't always the best choice. The small throat and clamping faces that are typically found within this variant can ultimately mean that a user requires a large number of sash clamps in order to properly secure a workpiece. However, with the help of a bit of DIY ingenuity, pairing up sash clamps with some self-built framing or rails can help deliver a firmer grip.

Quick-release clamps (typically one-handed ones)

The name really says it all in this case. A quick-release clamp provides fast gripping power and can be disengaged with a simple maneuver. Quick-release clamps tend to function with one-handed operation, making them ideal for assisting in general purpose work as across many different kinds of job. Bringing a quick-release clamp into the picture is fast and efficient, and it can replace your own hand when holding a workpiece steady. This frees you up to begin cutting, screwing, or manipulating the workpiece in whatever way you require.

Some of the best clamps in this category pull double duty, as well. Rather than just clamping objects together, the jaw can be reversed on some models, allowing you to apply pressure in an outward direction. This helps hold an object open rather than just ratcheting objects shut or keeping two pieces pressed firmly together. As is the case with clutch clamps and some others in this roundup, solutions featuring a quick-release gear that supports one-handed operation are often a go to choice for mechanics, woodworkers, and others. There are an abundance of solutions available in this category (and an Irwin selection pack features in our roundup of great woodworking tools under $100) so as you stock up on clamps you'll likely come across plenty to choose from.

Parallel jaw or cabinet clamps

These clamps are often lengthy pieces of equipment, much like a bar clamp or sash clamp. Parallel jaw options are sometimes known as cabinet clamps for a very important reason. This tool tends to be used in cabinet making because they are instrumental in gluing up bookmatched boards and other long pieces that can easily suffer from bowing when not clamped with high strength equipment. As the name alludes to, parallel jaw clamps feature elongated gripping surfaces that maintain a parallel hold across the length of the workpiece the clamp is being tightened around. These enlarged jaws offer an increased surface area for effective grip strength across a wider cross section of the boards you are trying to glue. They also feature flat bars that allow users to place them flat down on the ground in support of heavy panel gluing tasks.

This is a critical tool for any woodworking shop that puts out products ranging from moderate to large in overall size. If you are just working on simple, small picture frames and boxes at this stage in your woodworking career, this kind of clamping solution isn't likely to be necessary. But they serve admirably in tasks like building workbenches with laminated work tops, naturally in cabinet making processes, and even when tackling builds like a custom door for your workshop or in the house.

Face clamps

Face clamps offer a fairly small gripping surface. This might make them seem a bit less valuable than some other solutions in this hand tool category. However, face clamps perform their admittedly niche responsibility better than any other solution you might deploy. This kind of clamp features a handle much like the mole or vice grips you use when tackling stubborn propane tank connections and other wrenching requirements. Its locking mechanism allows you to apply tremendous pressure consistently through the clamping faces. Adding to the grip strength the tool brings to bear, these clamping jaws are located far away from the handles, producing powerful lever action forces.

That distance allows for a significant increase in holding capabilities, and it also delivers a wide neck to allow for deep reach around the object you are hoping to clamp in place. This tool is ideal for grabbing small work pieces and keeping the main body out of the way when tackling pocket hole joinery (with your workshop staple pocket hole jig) or making precision cuts in a workpiece. Face clamps often assist in locking an object down against your workbench or even as a means to provide additional holding capability when bringing an object to the bench grinder or belt sander for some detailed touch up work.

Hand screws

The hand screw is the only wooden clamp to make this list. Rather than featuring metal construction and potentially expensive components, this vintage piece of equipment will give woodworkers a taste of traditional hand tool-tool joinery practices. The hand screw is a fantastic clamping option when paired up with benches in your workshop. These tools can function in place of a vice to support customized clamping requirements at any position around your bench. They deliver a solid amount of work holding pressure, and there's one particular component built into these tools that can't be replicated by other clamping options.

Because the hand screw is made of wood, woodworkers can customize theirs to support specific and specialized gripping requirements. You can cut notches into your hand screws to allow for a specific gripping layout that can be customized to support repeat cutting requirements in your shop. This is an ideal solution for those who make multiple copies of the same thing on a routine basis. Moreover, with the basic clamping equipment you can even build the clamping heads yourself out of hardwood and craft hand screws that measure the exact dimensions you require to support specific jobs.

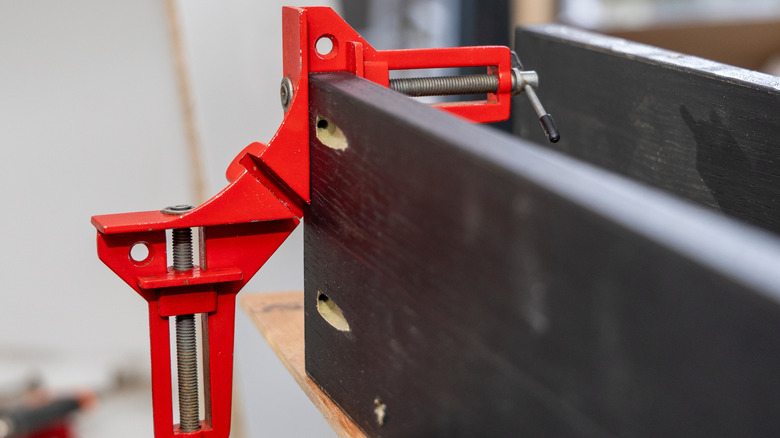

Corner/right angle clamps

The right angle clamp is a different kind of work holding tool than most others on this list. Instead of applying direct pressure to two work pieces to hold them together, the right angle clamp allows you to join up two boards at a perfect 90-degree angle. The clamp will hold your components in place, operating as something of a jig rather than a traditional clamping solution when compared to the standard bar and C-clamps you might be accustomed to using on more general builds.

The right angle clamp is also known as a corner clamp, and it is an instrumental tool to support construction tasks such as those surrounding picture frames and other squared off box type designs. Placing your work pieces into this type of clamp imparts a distinct confidence in the geometry of your final glue up. Rather than painstakingly trying to measure your corners and angles, using this clamp to support your build allows for fast movement from task to task and produces an extreme measure of precision. This makes it a critical solution for many woodworkers.

Spring clamps

The spring clamp is yet another work holding solution that isn't particularly akin to the standard clamping tool you may be used to looking at. Spring clamps aren't as robust as a lot of the other entries on the list, especially if you're gluing or planing boards. That doesn't mean that they aren't useful for a wide variety of other needs, though.

The spring clamp acts as a second hand in more ways than you can likely count. These tools feature a spring loaded mechanism that allows you to grip the back end and open the jaws quickly and easily. Letting go of the grips closes the jaws on the object to place the clamp on. Spring clamps hold down material and they can be used to grip accessory equipment like vacuum hoses, lights, and more. Spring clamps can quickly be operated with a single hand and allow you to lock essential features in place at a moment's notice. They're great for holding down stubborn material that might move around on your workbench, and they can help streamline your workshop's flow with ease.

Strap clamps

Strap clamps are the final conventional entry on this list. They naturally feature a strapping mechanism, to be placed around the perimeter of something you want to clamp in place. Once you have the strap set where you need it, you tighten down the gripping handle in order to apply pressure evenly across the entirety of the work surface. Strap clamps are particularly valuable when building boxes that require you to glue all four corners together at the same time. Gluing up the four boards and then placing one or more strap clamps around the perimeter helps apply pressure evenly throughout the entire build.

These clamps can be restrictive in size, however. You may find that larger projects go beyond the capabilities of a typical strap clamp. If this is the case, opting for a collection of bar or pipe clamps will frequently be your best bet. Even so, woodworkers frequently need to build boxes of all types. The box is a baseline skill within the world of woodworking, and in many instances these will be small to medium sized. Within this wheelhouse of the woodworking universe, the strap clamp excels as a phenomenal resource that can't be overlooked.

And then there's self-built clamping gear

Woodworking and carpentry may differ in some ways, but workers of both traditions will likely be familiar with a wide range of self-built work holding options. Clamps are a great solution to this need, but sometimes the tools you own simply won't get the job done like something custom. When this happens, building accessory features yourself could be the best solution.

People engaged in woodworking are naturally crafty. Woodworkers frequently look to build their own solutions to the problems they face. Rather than buying a new clamp with longer dimensions or a deeper throat, building a framework and then clamping that structure around your workpiece in order to provide the essential grip necessary to complete the task is frequently more satisfying and cost effective. You might also go this route when clamping delicate workpieces. Rather than strapping your clamp tightly onto a finished product's outer face, building a superstructure around the piece will let you firmly grip onto a sacrificial set of boards rather than the build itself. Any damage you might impart will then be inflicted on the sacrificial boards rather than the item you've been painstakingly crafting. Woodworkers are builders at heart, and building additional elements to support your clamping gear and specific requirements is just a part of the process.