10 Of The Worst Engines Major Companies Ever Put In A Production Vehicle

People often talk and share experiences about how good and reliable their cars may be. When you've made a good purchase, you tend to want to share your experience with others. However, most people aren't as eager to announce a poor shopping decision. Of course, with automobiles, oftentimes you won't know you've made a bad decision until it is entirely too late. What starts as a new and exciting experience with a fresh set of wheels can turn into a disaster with little warning, and once the disaster gets rolling, there may be no stopping it.

Having to deal with car trouble is the worst, and when that trouble rises above the level of a simple repair, things can get extremely frustrating. Worse still is when you have significant engine trouble and take your car to the shop only to be told it is a common problem, but not the kind of common problem that can be fixed in an hour by replacing a malformed hose fitting.

What we're taking a look at here is the kind of problem that requires the engine to come fully out of the car and have either a major service or replacement to get things right because something went wrong before the car left the factory. This is what makes an engine one of the worst on the road — inherent flaws built into them on the production line. Here are 10 engines worth avoiding.

Triumph V8

Triumph is a now-defunct English automaker that once was one of many companies building cars on the British Isles. Cars made by Triumph included several small two-seater roadsters powered by equally small 4-cylinder engines. The roadsters were at least modestly successful and several of them were sold in the United States including the Stag, which was built with an all-new Triumph V8.

Although Triumph had access to the legendary Rover V8, management chose to build a V8 from scratch. Engineers took their existing 4-cylinder and doubled it into a V. However, they retained the water pump placement but when the vertical block became tilted to make a V, the water pump sat up high in the V. This caused the pump to be starved of cooling water way too easily. If there was a leak, the first component to go dry was the pump, which would cause overheating and engine failure. Worse still, the water pump sat up higher than the radiator cap and made it nearly impossible to fill it completely. This contributed to the second factor with the head studs.

Half of the head studs were installed perpendicular to the block like other cars, and the other half were at an angle. When the engines eventually overheated, the heads stretched and warped and these studs became nearly impossible to remove. In fact, some customers even had their engines replaced with Ford or Buick engines instead of fixing the Triumph V8. These and other issues destroyed Stag sales, and Triumph would never make another V8 engine.

Cadillac V8-6-4

The Cadillac V8 is legendary in the American auto industry. Cadillac pioneered V8 engines as early as 1914, making them one of the first car companies to build them. However, by 1981, Cadillacs were too big and a fuel crisis left Cadillac scrambling for ways to gain more efficiency out of its oversized cars and engines. Using new technology engineers delivered a novel system meant to drastically reduce consumption — but ended up damaging Cadillac's reputation for years.

The V8-6-4 engine was a 6.0-liter V8 equipped with a new engine management system created by Eaton Corporation. It used throttle body fuel injection and had an array of sensors to monitor the engine. When certain conditions were present, the computer activated select solenoids on the rocker arms that would hold valves open to deactivate cylinders and the fuel injectors stopped feeding them fuel. This was meant to turn your big and powerful V8 into a more fuel-efficient V6 or even a 4-cylinder while cruising at highway speeds.

Unfortunately, it turned out that the computer -– which was built on 1970s technology -– was too slow to keep up, causing the system to fail to work and resulting in engines that ran terribly from the outset. Customers who brought their new 1981 Cadillacs back for service had the system removed altogether, and the V8-6-4 was not offered at all for the 1982 model year. It took decades before computers were fast enough to try this again, although this type of system is common today.

Oldsmobile Diesel

Diesel engines have long been known to be efficient consumers of fuel, but they present some tradeoffs when used in place of gasoline. They are more expensive to build, produce more torque and less power, and produce an ever-present odor from their exhaust. Regardless, Oldsmobile engineers tried diesel as a way to introduce improved fuel efficiency into its line of large cars.

Wanting to copy the success of European brands selling diesel in the United States, Oldsmobile used its proven gasoline 350 V8 as a basis for the diesel. They created a reinforced block of a stronger alloy –- meaning that it was not simply a gasoline engine with diesel heads slapped on it -– and topped it off with new diesel heads. Unfortunately, the resulting engine fell short from the start.

The power output was only 120 horsepower with 220 lb-ft of torque. Worse still, it was obnoxiously loud and plagued with an abundance of black smoke. In addition, the heads were secured by the same 10-bolt pattern as the gasoline version, which proved insufficient as the bolts began to stretch from the high compression required for diesel combustion. This resulted in blown head gaskets left and right, contributing to critical engine failures at Oldsmobile service departments everywhere.

The diesel calamity led to a class action lawsuit followed by the creation of lemon laws. Diesel engines were only offered from 1978 to 1985, and the bad experience destroyed the ability to sell diesel cars in the country for decades.

GM 3.6 High Feature Engine

The GM High Feature Engine was first jointly developed for the 2004 model year by Cadillac and Holden. It has been modified and used widely in multiple configurations and displacements across GM's brands for years. When in good running order, it has proven to be a fine engine -– until it's not. The 2.8 and 3.6-liter variants of this widely used engine platform sometimes developed a serious issue in year model cars from 2007 to 2010 in particular. This includes the Buick Enclave, the GMC Acadia, and the Cadillac CTS, among others, although GM claimed to have rectified the problem by the 2012 model year.

The primary concern for car owners with this engine is the timing chain. This keeps the valves opening at the right time, and this engine utilizes variable valve timing, meaning it has hydraulic cam phasers driven by the chain adjusting when they open. It is imperative this chain be kept tight and well-lubricated for proper operation. However, if the timing chain begins to stretch, owners will first see a check engine light followed by a rattle under the hood, especially at idle.

If left unchecked, engine misfires may occur and metal shavings will show up in the oil. Catastrophic engine failure is possible in extreme circumstances, and a new engine can cost $7,000. Even those who catch it early can expect a bill of around $3,000 for the timing chain replacement.

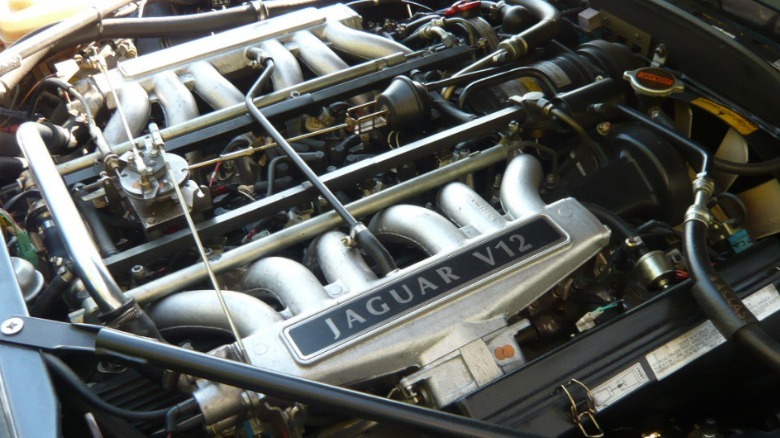

Jaguar V12

There are few comparisons to the sporty yet elegant styling and the fine English craftsmanship of a Jaguar automobile. The company is responsible for many highly collectible classics, including the revered E-Type, and continues to build aspirational machines today. A V12 was first installed in the E-Type but then went into the XJ-S and XJ12 until it was retired in 1997. Primarily found in the XJ-S but also XJ12 models, the V12 is a fine piece of machinery -– until it needs repairs.

A peek under the hood of an XJ-S can be frightening. Atop the engine is a wicked maze of wires, vacuum hoses, and fuel lines that looks daunting even to experienced technicians. The cooling system of this engine could be described only as adequate while also being overly complicated, as it uses an unorthodox design with little tolerance for temperature fluctuations. Engines that experience even mild overheating for relatively short periods can experience a dropped valve seat and potentially costly repairs.

However, perhaps the biggest headache can be the electrical system provided by Lucas. Systems from this British auto supplier are notorious for being temperamental and unreliable. Many of their parts were outdated when new and problems were difficult to track down, often due to multiple failures occurring at once.

Maybe it is not fair to say the Jaguar V12 is the worst. The engine itself is relatively robust, but keeping it running can lead to costly repairs and undue stress. At least the cars are beautiful.

Mazda Miller Cycle V6

Japanese automaker Mazda has a long history of creating unusual engines. Part of its legacy has been built upon its version of the Wankel rotary, perhaps the most successful rotary engine ever built. It also once produced a 1.8-liter V6, which is among the smallest V6 ever sold in a car. So in the late '90s, it wasn't a huge surprise when Mazda's upscale Millenia came with an engine relying on the Miller Cycle.

The vast majority of 4-cycle engines use the Otto cycle, which developed in the 19th century. With the Millenia S, you received a car with a supercharged 2.5-liter V6. However, the supercharger was not installed to boost power, it was necessary for the Miller Cycle. The details of this cycle can get a bit wonky, but, in short, compression happens in two stages by leaving the intake valve open longer. The supercharger is added to maintain compression, and the end result is improved efficiency.

Unfortunately, the problem with the Millenia is the supercharger. While good information is scarce today, looking through sites such as Repair Pal and Car Gurus reveals many complaints of excessive oil consumption, which can lead to other problems, with repair estimates commonly around $3,000. When I worked in the parts department of a Mazda dealer in 2007, I spoke to multiple techs who said bad superchargers were common and that the Millenia was a nice car so long as you did not get the S model. With so few on the road today, few people are left who know what to do with one.

Cadillac Northstar V8

As Cadillac's first dual overhead cam engine, the 1993 Northstar V8 was a sophisticated and powerful engine that helped the brand catch up technologically to European and Japanese competition.

Initially, this was a 4.6-liter V8 with port fuel injection and all-aluminum block and heads designed solely for front-wheel-drive cars, although it was later configured for the SRX and XLR. It was a technological achievement with many new cutting-edge features for electronic engine management. Northstar engines first arrived with a 295-horsepower output, although this was increased to 469 horsepower with the XLR-V Roadster and STS-V. Cadillac eventually went back to making its cars rear-wheel-drive and retired the Northstar in 2010.

However, some Cadillac owners have experienced blown head gaskets. The heads are installed with torque-to-yield head bolts, which are a single-use product intended to stretch during installation. Over time these bolts have been known to continue stretching, causing coolant leaks and overheating. The only way to repair it is with new head bolts, preferably using a kit to install thicker and stronger replacements. A SureGrip Stud Kit can permanently fix this but it requires the engine to be removed and will be a costly repair, which becomes less attractive as these cars age and lose value.

Ford 1.0-liter EcoBoost

While it is no longer available in the United States, from 2018 to 2022 the cheapest car available from Ford was its diminutive EcoSport SUV. This is a small vehicle built for world markets by Ford in India, brought into the American market to offer a low-priced vehicle. When Ford pulled the plug on Indian manufacturing, the EcoSport went away with it, too. Buyers won't be missing much as it was generally a cramped and uncomfortable car trimmed in cheap plastics and powered by an anemic little 3-cylinder engine, the 1.0-liter EcoBoost.

To make sure you don't get the wrong idea, the little EcoBoost is not inherently bad because it is small. The problem manifests inside where all the oily bits are. The oil pump is driven by a belt exposed to the engine oil. Owners have shown up to dealers with low oil warnings and even engine failures due to either a bad oil belt tensioner or a completely worn belt. This has also caused bits of rubber to get into the oil, clog the pickup tube, and starve the engine of oil. Furthermore, if bits of rubber are clogging the tube, smaller particles are surely circulating throughout the engine, potentially clogging small oil passages within.

This issue has happened enough to prompt the National Highway Traffic Safety Administration (NHTSA) to open an investigation. A wet belt is not unique to this engine, as GM and Volkswagen also have engines with wet belts and no significant failures, but something about it doesn't feel right.

Chrysler 2.7 V6

Found in a variety of Chrysler cars from 1998 to 2007 was the LH engine, produced in 2.7-liter and 3.2-liter variants. They could be found in the Sebrings, Concordes, and Intrepids of the day, providing decent power and efficiency but not necessarily excelling at either. However, it did cause some owners grief when serious problems showed up only after several years on the market.

A couple of years after purchase, customers started to complain about problems with the engine. Mechanical inspections revealed an alarming amount of sludge buildup within the crankcase. By 2004, the Center for Auto Safety (CAS) had received 92 complaints about the engines while the NHTSA had more than 400. Engine repairs were costing car owners thousands of dollars and the CAS called upon DaimlerChrysler to issue a voluntary recall on all 1998 to 2002 Chrysler vehicles with the 2.7-liter V6.

It turns out that a poorly designed water pump allowed coolant to leak into the crankcase, turning the oil into a gel and blocking oil passages. This could lead to complete engine failure. A class action suit was filed against Chrysler, with the company appointing a third party to administer claims, although claimants complained that Chrysler made it extraordinarily hard to get approved for relief.

Ford Triton 5.4

Labeling the power source under the hood of millions of Ford trucks may prove to be a controversial choice, but it merits discussion. The Triton 5.4-liter in the F-150 is a V8 engine with overhead valves and three valves per cylinder. This engine has been installed in millions of Ford pickups and it provides a good blend of power and economy in a robust package. Ford truck owners will swear by them and many will be proud to show you the many hundreds of thousands of miles on them. Sadly, not everyone can tell the same tale.

Ford 5.4 V8 engines are generally very reliable. However, in some engines, sludge builds up in oil passages and causes problems with the cam phasers for the variable valve timing. This usually manifests as a ticking sound on the right side with trouble codes regarding cam and crank position mismatch that can lead to poor performance or catastrophic failure if left to fester for too long. Phaser repair alone can cost up to $2,500. Additionally, before 2003, some engines suffered from spark plugs being blown out for a lack of threads in the head. Some 2004 to 2008 models use a two-piece design prone to break during removal, leaving a costly mess to clean up.

While there may still be countless trucks on the road with no issues, stories about them have scared away buyers. In fact, the popular YouTuber and mechanic Car Wizard claims he has replaced too many 5.4 engines to count and recommends that nobody buy them at all.

Ratings

Determining what is the best or worst engine can be a bit of a subjective affair. Furthermore, many people have had great experiences with engines that others have deemed to be unreliable or poorly engineered. The inclusion of an engine on this list is not meant to be an indictment of every copy of a particular engine.

Regardless, the engines chosen for this article all have a major flaw inherent to the design that was present when they left the factory. The decision to include these engines has been based on a mix of public reporting and user complaints. Those with the most complicated and expensive anticipated repairs were chosen for this article.