Mazda's Iconic Rotary Engine Explained: How It Works And Why It Went Away

The rotary engine is unique in its success and failure and its ability to make an impact with a completely different way of thinking. As it is, every production car for the last 130 years, aside from electric and early steam-powered models, relies on a reciprocating piston internal combustion engine. This uses cylinders with pistons to compress air mixed with fuel, which is detonated to turn linear motion into rotational force. This is the engine Karl Benz used on his Patent Motorwagen, the first automobile ever made, and it is the same type of engine used on the latest S-Class. Others have designed and built prototypes of alternate engine designs, but none made it into production, except the rotary.

The rotary engine is best known for being championed by Mazda and installed in its RX-7 and RX-8 sports cars for many years. It's also the most misunderstood engine, especially by mechanics who have trained and worked only with piston engines. This leaves the rotary to be championed only by enthusiasts who often have an obsession with all things rotary that's borderline unhealthy. However, thanks to this select group of weirdo geniuses, the rotary is living long past its expiration date in workshops dedicated to Mazda sports cars. It helps that Mazda makes cars with excellent handling, good build quality, and that are fun to drive. But many are uninitiated into the world of the Mazda rotary engine.

Felix Wankel biography

The rotary engine was invented by Felix Wankel, and is often referred to as a Wankel engine. Part of this is to avoid confusion with an aviation rotary engine that has its cylinders arranged outwardly from the crankshaft in a circular pattern. Wankel is from Germany, growing up through the tumultuous period of the early 1900s and surviving two World Wars. Some of the work that would eventually go into his engine design began while working for the Nazi government. After the war, he was imprisoned in France and his lab confiscated by the government, but he was eventually released and was free to continue pursuing his engineering ideas.

Wankel was an impressively intelligent engineer, especially considering he lacked any university education and was completely self-taught. In 1929 he filed his first patent with engineering that would eventually become the rotary engine. He began working at NSU, a German automaker, contributing to engineering for car production while also working to develop his engine. A working prototype of a Wankel engine was first presented in 1957. NSU and Wankel took its new engine and showed it around Germany to automotive and engineering press, eventually placing it in a modified NSU Prinz for demonstration. In 1964, the NSU Spider became the first-ever production car powered by a rotary engine. While NSU would never have great success and was eventually bought by Volkswagen, the engine showed great promise and brought many licensing deals.

The Wankel prototype

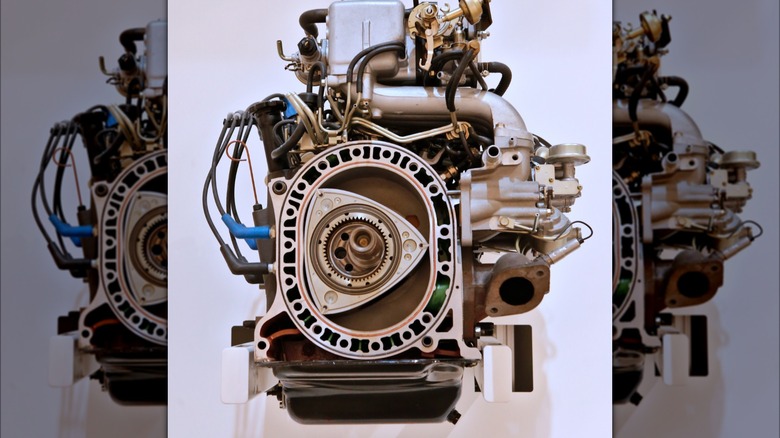

The working 1957 engine Wankel had created was an innovative breakthrough. This was the first working engine design that did not use pistons, valves, and cylinders, but a tiny triangle spinning inside a housing to make power. However, though the prototype worked, it needed refinement and the design was not practical for mass production. In Wankel's first engine, the rotor and housing both spun inside a larger case. It was complex and bulky, and one of Wankel's colleagues, Hanns Dieter Paschke, devised a change that made the rotor housing fixed, making the rotor spin an eccentric shaft, roughly equivalent to the crankshaft in a piston engine, that would transfer motion to a final drive.

The revised engine is made of essentially three parts, the housing, rotor, and eccentric shaft. The housing is an oval shape while the rotor is a triangle with convex sides. Each side of the rotor is sealed against the housing, creating a combustion chamber. Ports are added to allow for intake and exhaust, and a spark plug is installed in between the ports. As the rotor spins, it takes in the fuel mixture as the combustion chamber passes the intake port, then pushes the air and fuel around, compressing it as it goes, and, when it arrives at the point in which the combustion chamber is at its smallest, the spark plug fires, pushing against one tip of the rotor. The combustion chamber then passes over an exhaust port to empty the spent gasses, starting the process again as it turns further. The result is an Otto-cycle four-stroke engine, just like most other engines today.

The first rotary cars

The first production car with a rotary was the NSU Spider in 1964, a small and lightweight car perfect for the 50-horsepower single-rotor engine. The redline was set at 6,000 rpm, but the engine could actually go much higher as it doesn't contend with valve float or the damage from pistons being jerked back and forth too fast. A rotary theoretically has no redline, however, heat will cause oil to break down and steel to eventually melt and fuse together. The Spider is an attractive little sports car that was priced competitively but failed to gain much traction. NSU released the Ro80 sedan released in 1967, an attractive small sedan built to showcase the engine technology, this time with two rotors. It was an innovative car with independent suspension and a semi-automatic gearbox wrapped in modern styling.

The Ro80 developed problems early on. Problems with the rotor apex seals frustrated consumers already upset about its high fuel mileage. They also experienced difficulty getting the engines started and the engines tended to smoke a lot from oil getting past the rotor seals. When they ran, the little rotary engines were smooth running with little to no vibration. Yet some owners, frustrated with the mounting problems, swapped their innovative rotaries for the Ford V4 engine, which was notorious for its intense vibrations and rough running nature, further devaluing the ownership experience. The future success of the rotary engine was not guaranteed by the time the 1970s came along.

Other rotary research and experimentation

Fascinated with the prospect of new technology, several manufacturers licensed the Wankel design and built prototypes for future models. The companies that did this include General Motors, Audi, Citroën, and even Rolls-Royce. Chevrolet planned a Corvette with a mid-engined rotary and the AMC Pacer, relying on GM to supply a rotary engine, had to have the AMC inline-6 crammed under the hood at the last minute when GM canceled its rotary program. Citroën licensed the technology for its GS Birotor which debuted in 1975. This was a follow-up model to the wildly successful DS, and the company known for its cutting-edge innovation was eager to give this new engine a try. Only 847 copies were sold and most suffered from failed seals before they had racked up 20,000 miles.

Another experiment with the rotary comes from Roll-Royce. Engineers created a sequential dual-rotor diesel engine that used a smaller rotor as a compressor that fed the larger rotor the fuel and air mixture to be detonated by high compression in the second rotor chamber. It was built but immediately canceled. Others made rotary vehicles that made it to dealerships. Suzuki sold its RE5 rotary motorcycle as did Kawasaki with its X99. Norton saw the most success with it, creating and selling several rotary motorcycles into the 1990s. Even with these minor successes, the rotary still never caught on with most who tried it.

Mazda rotary dedication

Mazda has a reputation for being the plucky upstart creating original products with historically low levels of resources. As it worked to evolve from a small manufacturer of tiny cars for the Japanese market only into a worldwide competitor, it also saw potential in Wankel's design. The inherent problems with sealing the rotor were evident from the start, and even NSU experienced huge problems in keeping customer cars on the road. Mazda chose to license this technology as a way to set the company apart and use innovation as a survival tool. Chief among the problems with the design was the tendency for the rotor apex seals to scratch the surface of the rotor housing. If the seal does not move smoothly across the surface, tiny hops occur that create the scratches.

Mazda dedicated itself to alleviating this problem and its engineers came up with a solution. Apex seals made from graphite-aluminum alloy proved to glide over the surfaces smoothly and also cured problems with oil consumption and a low-end torque deficiency. It then created a halo car that was built not to make money, but to prove Mazda was a contender in the market with a world-class sports car. This car was the Cosmo Sport, which was released in 1967 and featured a 1.3-liter dual rotor engine, and it kicked off a long line of Mazda cars with unique engines.

Mazda rotary lineage

The first production passenger car, the Cosmo Sport, was hand-built in a special workshop, made by Mazda to come with a rotary was the Familia Coupe, or R100 in some markets. For Americans, the first rotary available was the RX-2 in 1971, followed by the RX-3 and RX-4. It was also at this time that the REPU rotary pickup was produced and sold only in North America. However, a lack of torque from the rotary engine meant it was short-lived. A version of the Mazda Cosmo was also exported to the U.S. in 1976 and 1978. Sales were low and it's nearly impossible to find today.

Mazda introduced its RX-7 sports car and finally had a hit worldwide. The RX-7 is a nimble sports car built with near-perfect weight distribution that is powered by a 1.3-liter dual-rotor engine. Although it never delivered huge power, it was comfortable at high rpm and, coupled with excellent handling, made the RX-7 a fantastic car for winding roads and slalom courses. Production continued into a second generation, which is also when the first turbo rotaries arrived, showing even more potential from this novel power source. The third generation of the RX-7 brought us a sequential twin-turbo model that combined stunning performance with exotic good looks in a package that is now among the most desirable of Japanese sports cars of the '90s. Increasing prices prompted its cancelation in 1995 (2002 in Japan).

The demise of the Rotary

Part of the RX-7 cancellation was ever-stricter emissions regulations and the difficulties in making a rotary burn clean. Nonetheless, Mazda went back to the drawing board and developed a new rotary engine that could meet the new guidelines. It was dubbed the Renesis rotary and it came in an all-new RX-8 sports car. The RX-8 featured small reverse-hinged doors that allowed access to the rear seats, making the new car a four-seater — the rear seats were only suitable for kids. The RX-8 debuted in 2003 and lasted until 2012, undergoing a mid-cycle refresh to update its styling. The engine remained the same throughout, providing a modest power of just 237 horsepower at a time when sports cars were heading toward 400 horsepower as a norm.

Although the car was a good-looking model that had excellent handling, even if it was a bit underpowered. As the car approached a decade in production, sales began to falter. But demand is not what led to cancelation. Tight EPA emissions regulations spelled doom for the rotary engine. Increasing fuel economy while lower output of polluting gasses made it pretty much impossible for Mazda to engineer an engine that could be sold for road use. 2012 was the last model year for the RX-8 and that is when Mazda finally put its rotary technology to rest.

The future of rotary engines

Mazda forums have circulated rumors of a revamped and revived RX-7. But time after time, Mazda leadership made clear pronouncements that no such revival was in the works. Further fueling these rumors have been many artists' renderings of modern RX-7 concepts being spread online by fan forums and unscrupulous automotive websites. It doesn't help that Mazda released images of an RX-Vision concept in 2015, which looked like a new rotary concept for a two-seater sports car, but it was never more than a concept.

Recent news from Mazda has shown updated renderings of what looks like new sports car designs, but they have come along with announcements that Mazda will be putting forth efforts to create all-electric cars in the near future. In the age of the EV, it seems highly unlikely for any company to bring back an engine notoriously difficult to burn clean. However, the rotary is not dead yet. Mazda has introduced a new powertrain for its MX-30 EV, which has an abysmal range of just 100 miles and will now include a rotary engine range extender. This novel setup seems like a good idea on its face. Rotary engines are extremely compact, and simple, and are fine running at high rpm. This makes them good candidates for a continuously running generator, which can charge the MX-30 and increase its practical usefulness by orders of magnitude. This appears to be the future of the rotary engine.