5 Woodworking Tools That Users Say Are Actually A Waste Of Money

The tools of the trade for woodworkers form a complex and sprawling layout of gear. Some woodworking tools are small, handheld pieces of equipment, while others are substantial pieces of furniture. There are a great many important woodworking tools that beginners can get a lot out of for less than $20, but at some point everyone will need some technically demanding and large tools. That's when you'll probably start looking at the power tools that can make you a better woodworker, some of which feature a particularly high price tag. The journey of a woodworker certainly isn't a straight path, and everyone turning wood stock into amazing creations will seek what helps with their own interests and capabilities.

However, there are some tools that tend to get less use than others. For instance, unless you're a bowl maker or build furniture with spindly components, it's likely that your lathe isn't a main component of the workshop. There are a few specialist tools essential for woodturning that are staples of some shops that are completely absent from others. Some woodworking tools often take up too much space and cost more than the average woodworker will be ready to spend, and they aren't very useful outside very specific conditions. They can be valuable for some, but on the whole these five tools tend to be a waste of money.

A large domino jointer

The domino jointer is a specialty tool. Right off the bat, this makes it a potentially poor candidate for woodworkers looking to augment their collection. Domino jointers do one thing, and it's a task that you won't need on a regular basis. Specifically, this tool works like a plunge router to cut specially shaped recesses into boards. Dominos are one way to add strength during the glue up process. Cutting these holes in the side of a board and then adding a wide and flat dowel into the newly cut recesses allows you to add surface area when gluing and provide a little extra structural integrity. This can be a useful feature when crafting bookmatched stock for things like chair seats or even tabletops.

The reality is that, in most circumstances, there are plenty of alternatives to the domino. This makes a power tool dedicated to this function useful in some contexts, but unnecessary in most others. To compound the domino jointer's lack of value for most woodworkers, the most prominent examples of this gear come from Festool, a brand known for being excessively expensive. Even if you do need a domino jointer, go with the regular model. Large domino jointers are two or three times the price of their standard sized alternatives, and neither solution will give you anything beyond niche functionality.

A benchtop jointer

The benchtop jointer is a seemingly valuable alternative to the full-sized shop model. Jointers are powerful pieces of equipment that help professional woodworkers cut lumber with perfectly square sides. The jointer is a key element in a large shop setting, and for this reason many aspiring woodworkers look eagerly to a future in which they can add one of their own into the mix. It's important to note that a jointer isn't a tool that provides singular utility. The jointer must be used in combination with a planer or alternative cutting tools in order to both flatten and square the boards on every face. This is one of those woodworking tools that beginners will want to avoid, since they don't yet have the knowledge to effectively use this expensive piece of equipment.

Because of the drawbacks of a full-sized unit, many home woodworkers and those in smaller shops might consider a benchtop model instead. However, there are numerous issues that come with a typical benchtop jointer. These are smaller than regular jointers and are more affordable, but they can't cut stock as long or wide as a standard unit jointer. This can quickly become a problem for even small scale hobbyists. They also tend to feature aluminum tops rather than cast iron, which can warp over time. Rather than scaling down your purchase by buying a smaller unit, if you are committed to adding a jointer to your shop, your best bet will be to look for used equipment.

A jobsite table saw

Table saws have an important place in any woodworker's shop. A table saw allows you to rip boards down their long length, as well as offering the ability to cut angles and miters. Additionally, table saws tend to include numerous guides that help lock in the exact dimensions you require for precise, repeated cuts. This makes your table saw capable of providing coverage for much, if not all, of your miter saw requirements, too. However, the tool marketplace is flooded with options, and different woodworkers will require a different solution. The table saw is a critical piece of equipment for renovation and building projects, and so many saws of this nature are portable, 'jobsite' tools.

A jobsite table saw prioritizes lightweight builds, quick setup and tear down, and versatility. These tools are used across a huge range of tasks, and therefore act as something of a generalist cutting implement. To help with this kind of approach, jobsite saws tend to feature flimsy and short fences, aluminum work tops, and other features that can be useful when tackling renovations and general cutting work, but sacrifice the precision that a woodworker demands of their equipment. You can absolutely get away with using a jobsite saw when you're starting out, but those serious about building their skills and tackling increasingly more demanding projects will quickly require an upgrade; so much so that they might want to skip a jobsite table saw entirely.

A drill press

Drill presses are a niche tool that tend to get used sparingly. The drill press takes up a lot of space in your workshop, and can therefore be a wasteful purchase for those working in small settings. Drill guides can instead be used in tandem with your standard power drill to achieve the same result, if only on a basic level. This accessory is compact and easily stored away when not in use, whereas a drill press is bulky, heavy, and requires you to permanently sacrifice a corner of your workspace. The drill press is a tool that only does one thing, although it does function as a solution for cutting all kinds of stock beyond wood. This tool is undeniably the best way to tackle drilling holes, but if this isn't something you do daily, the drill press is a waste of space and money.

Drill presses are also somewhat difficult to use, even though they look fairly straightforward. Rather than using a single knob or sliding lever, operating drill presses require an intimate knowledge of the tool and how it functions. This is a piece of shop equipment more so than a tool in the traditional sense, and giving it the respect it demands involves understanding both the nuanced operation of the equipment and the danger it can pose to those who don't have the knowledge necessary to navigate it.

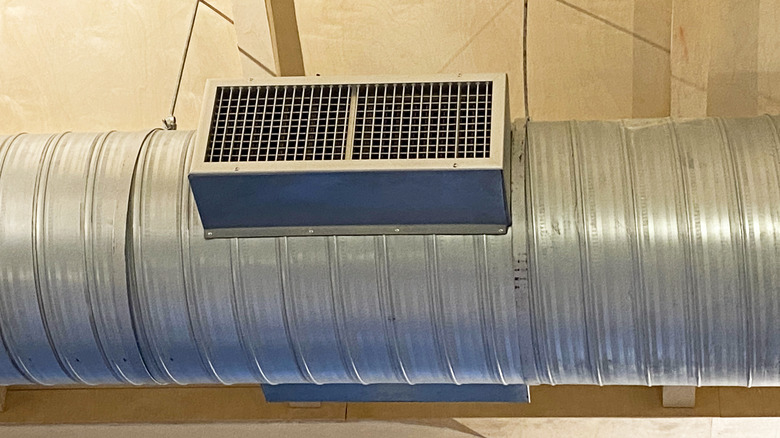

Air filtration units with prioprietary filters

Air filtration is an important thing for any enclosed workshop. If you're working out of your garage, you can open the door and get fresh air flooding into the room with ease. However, this isn't possible for all woodworkers. Moreover, if your workspace doubles as a soldering station, or you dabble in welding or other works, additional environmental management tools and equipment aren't just nice to have, they're essential safety measures.

An air filtration unit can be as simple as a fan and filter or far more in depth, involving ductwork and other elements. Where you can run afoul when investing in air filtration systems hinges on a lack of research in one particular area. Experts tend to suggest introducing units that include good HEPA filtration, which require an occasional change of the filter. This is a good suggestion, but before investing in any air filtration tool, it's worth exploring the cost of replacement parts. It's entirely possible to invest in a unit whose cost will be outpaced by the filter's replacements after just a few years.

One red flag to keep in mind involves the availability of replacement options. If the company that makes your unit is the only brand on the market building filters for that model, you're looking at a potential scarcity bottleneck in the future, when the brand inevitably brings in newer options and phases out the one you're using. This situation is easy to avoid: just invest in a filtration system with an abundance of third-party makers that support the solution's accessory needs.

Methodology

The products on this list are all highlighted by experienced woodworkers as tools they have bought but don't use often. Most are at least moderately expensive, making their inclusion in most shops superfluous, and something that users should probably avoid. I've had the privilege of using some of these tools in the past and got some use out of them, and any tool you get value from can be a useful addition to your workshop. However, for the average tool owner, these tools don't offer enough utility to justify their inclusion in a garage, shop, or toolbox.