5 Outdated Tools And What We Use Now Instead

From ancient times to the modern day, humans have worked together to build and achieve great things. Structures like the pyramids at Giza and the Roman aqueducts as well as machines like the trebuchet and the steam locomotive demonstrate human ingenuity, cooperation, and determination. But something required to make all of these things, beside people, are tools. Without tools, nothing gets built or manufactured, or at least not nearly as efficiently. Fortunately, tools of all varieties have been with us through the ages, changing to meet the demands of new generations and the things they create.

Just as buildings change as populations swell and technology introduces ever-changing machines and devices to enrich our lives, the tools we use to build and repair things change with time. Implements once used on a pre-industrialization farm would be inefficient if not foolish to use today, just as hand tools made for mending a stagecoach would be woefully inadequate for tuning the latest 700-horsepower 2025 M5 from BMW. It is just a fact of life that tools will change, and to demonstrate just how much change has taken place during the modern period, here are five tools largely made for use on automobiles that are now deemed to be outdated, and what replaced them.

Air tools

If you have ever walked past an auto repair shop with its garage doors open, you have heard the familiar sound of air tools in use; probably that of an impact wrench. Particularly helpful when removing or installing wheels, air-powered impact guns produce an unmistakable noise that is loud enough to be heard from some distance. Regardless, these are the workhorses of any garage, and they significantly cut the time and effort required when using hand tools. And yes, they are still in use, but their end is already in sight.

In most shops, technicians own their tools and flat rate labor pay provides an incentive to buy tools to save time on every job. Air tools have traditionally been the best bet, but recent developments in battery and motor technology have put cordless tools in an attractive position as an alternative. Although they require charging periodically and air compressors can provide consistent power for hours on end, the lack of a hose to become entangled with is a big advantage. Furthermore, these advancements, especially from brushless motors, have also put the power available from cordless tools at least on par with air tools. For these reasons and more, air tools have lost their once dominant position in the tool box.

Engine analyzer

Automobile engines have come a long way over the last 100-plus years. What is now precisely controlled digitally by microprocessors used to be a wholly analog affair. Creating the optimal environment to achieve peak efficiency had to be achieved by a technician measuring various components and performing adjustments to extract as much energy as possible from every ounce of fuel burned.

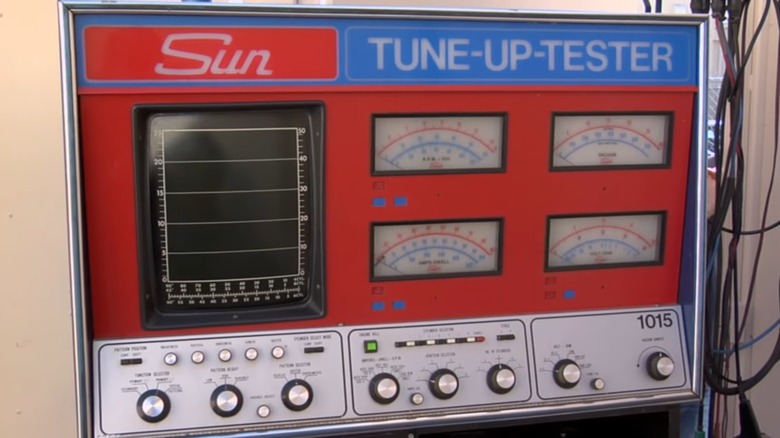

To properly tune an engine using measurements such as voltage, vacuum, and ignition timing, every reputable shop once had an engine analyzer, more often than not manufactured by Sun, which is now a subsidiary of Snap-On tools. These enormous machines had everything you needed to know what an engine was doing, but only if you knew how to read the various analog gauges and scopes. Being twice the size of a refrigerator, only professional shops had them, although smaller consumer grade models were available.

Today, analog machines are completely obsolete. Most of the adjustments one would make to tune an engine are automatically set by the computer. The introduction of electronics to engine controls began in the late '60s, eventually taking over all engines in cars and trucks. Today, a variety of OBD2 scanners can tell you everything you need to know, including apps you can download to your phone and use with a Bluetooth connector plugged into the car. While professional scanners can cost thousands, they will never need their own parking spot in your shop again.

Screwdrivers

You might be thinking this is a mistake, because screwdrivers are obviously not outdated and very much in use pretty much everywhere today. While this is true, some context around the development of the screwdriver will help this choice make sense. Screws themselves date back centuries, making screwdrivers a very old tool. However, of the multiple types of screws and screwdrivers we have available today, only one seems to predate the modern age.

Perhaps because it is the simplest design, screws seem to have all been slotted at one time. This means even the most complex of old machines only used slotted screws. This includes early cars, airplanes, and locomotives. Anyone who has used a slotted screwdriver to any degree knows how frustrating it can be to keep it aligned, especially if you are working with one screw after another. At some point, inventive individuals began to think of a better way to keep things together. And while there are many who did create functional alternatives, John P. Thompson receives the lion's share of notoriety for changing fasteners forever.

Although Henry F. Phillips did not invent it, the Phillips screw is named after him and his company. After acquiring the design, the four-point screw first appeared on a mass-produced product when Cadillac introduced them to their assembly line in 1937. Since then, it has proliferated across industries worldwide to become one of the most commonly used fasteners on the planet. And while many superior types of screw heads exist, the Phillips screw holds the record for first making the slotted screw outdated.

Microfiche reader

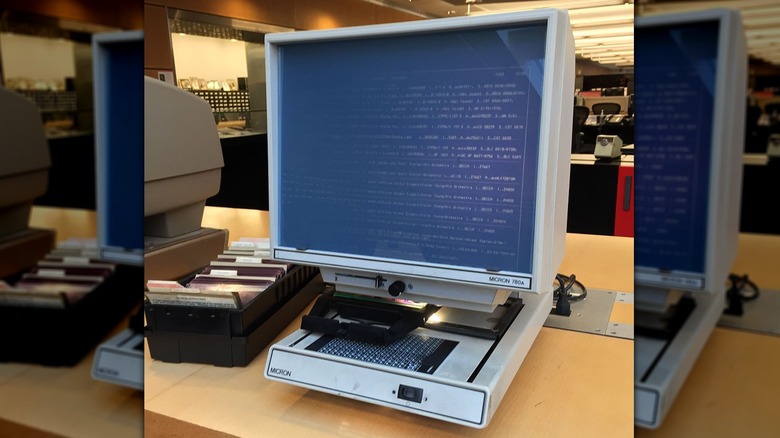

Chances are that many younger readers have had little to no exposure to the once popular medium of microfiche. This is a film that was once extraordinarily useful in condensing a large amount of information into a very small package. For example, an entire encyclopedia could be reduced down to a handful of film sheets stored in a single binder. To access the information, the film had to be loaded into a reader consisting of a light source, magnifying glass, and a screen. It is a tool that was once widely used across industries.

These were also once an indispensable tool found in new car dealerships and parts stores everywhere. Before the proliferation of computer catalogs, microfiche readers were used to see parts diagrams to look up part numbers. They made the work considerably easier than using vast paper catalogs predating microfiche. A parts counter employee needed to know in what part of the vehicle or in what system the desired part was located to pull the correct film from a folder and load it into the reader, but once they did, the diagrams could be viewed very much the same way we read a PDF today.

While microfiche was once a major time-saving tool, it has since been replaced by computer catalogs. Wards Auto reported in 2001 that GM had computerized its entire parts catalog, phasing out microfiche for its dealers. Computers now dominate the industry, although microfiche archives are still used today, particularly for vintage or antique vehicles and other kinds of machines.

Timing light

You may know that a combustion engine needs fuel, air, and fire to function, but equally important to that combination is the timing in which it all happens. Valve timing lets fuel and air in and out of the engine at precise intervals. Separately, ignition timing ensures combustion begins at the optimal moment to ensure smooth operation.

Historically, engines handled spark timing with a mechanical distributor driven by the camshaft, which delivered a spark based on the rotation of the crankshaft, the timing of which could be adjusted by changing the position of the distributor. To measure and adjust the timing, mechanics used a timing light. Using an inductive pickup hooked over the spark plug wire, the timing light flashes every time electricity is sent to the spark plug, and a line on the rotating flywheel, located on the end of the crankshaft, can be seen with each flash. Using a gauge on the front of the engine, the distributor can be turned until the line is at the correct position, thereby making the engine "in time." It is a simple and effective tool, but it is also obsolete.

Today, everything is handled electronically. Timing is set and adjusted by a computer with a microprocessor, which makes the spark timing perfect every time with no need for adjustment. Timing lights are still useful when working on classic cars, but they have no use on modern cars at all. They've been replaced by the car's on-board computer.