What Are Transmission Synchronizers & How Long Do They Typically Last?

The principle behind manual transmissions in cars is that the driver has to manually change gears, which sounds simple in theory. Press in the clutch while releasing the throttle, shift, then release the clutch — on the surface, that's all you ever notice. Actually, what you're doing is trying to force two objects spinning at different speeds to engage with one another.

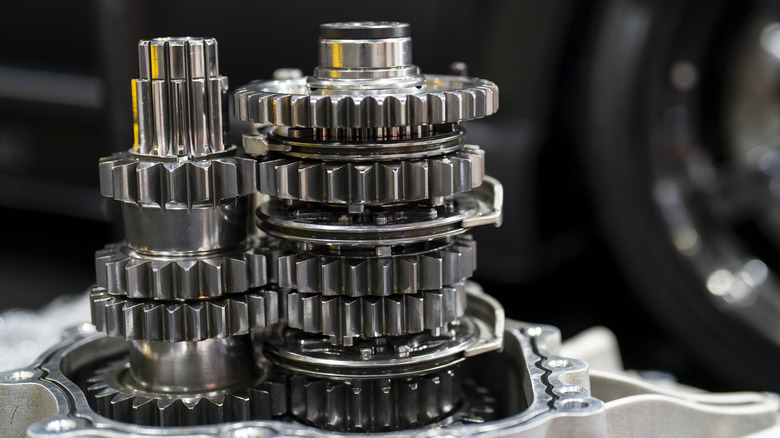

So, how are gear changes in modern cars so smooth? The magic lies in the synchronizers, a set of collars in between gears that mesh with the gear you select and synchronize its rotation.

All synchronizers feature a few common components shared between them: Sliders, blocker rings, and the teeth that actually mesh with the gear itself. The way it works is similar to a clutch in principle, using friction to bind the gear to the synchronizer, and then lock it in place with the teeth. Of course, that means that this surface is subjected to all the mechanical strain associated with such forces, and therefore it'll wear over time.

How much time does a synchronizer last, though? Due to developments in hardening processes, synchronizers can typically last into the six figures of miles, and just like any part that uses friction to function properly, taking it easy with your shifts will make it last longer. Some typical signs of worn synchros include difficulty shifting, being stuck in gear, or jumping into neutral; all quite common issues with worn-out manual transmissions. Let's explore more and discuss how they work and what to do if yours start failing.

How synchronizers work

Synchronizers are effectively tiny clutches fixed to a collar that's mounted on the transmission shaft, found on manual and sequential manual gearboxes. The gear it's engaging is spinning at a different speed, so its job is to match the speed of the shaft with the gear you're trying to select.

Synchronizers feature various components, beginning with the hub itself which spins with the gear shaft and contains a collar, or blocker ring, that slots over the selected gear. The inside of that collar has a brass ring, on which are fixed a set of pointed teeth. As the hub matches the speed of the gear through friction, the collar slots onto that gear and meshes with the teeth to form a positive lock.

Think of it like interlocking your fingers together so your hands move together. That brass ring is actually what binds together with the gear, bringing the gear to the same speed as the shaft and allowing the collar to lock on smoothly. Those pointed teeth on the synchronizer ring then lock into pointed teeth on the gear; the points help locate the teeth so they don't skip.

The key factor here is pressure. The act of shifting applies pressure to the synchronizer, forcing it to contact the selected gear before it fully locks, a state called pre-synchronization. As the speed matches, the teeth on the collar engage with the brass ring, and the assembly slides neatly into the slots on the gear itself. It sounds complicated, but the basic principle is this: Pressure forces three sets of pointed teeth to mesh, therefore forcing all of the elements to rotate together.

Signs of worn-out synchros, and what to do to prevent it

Not every car actually has synchronizers; many vintage cars and commercial trucks don't, for instance. In those cases, a driver must manually adjust the shaft speed themselves by letting off the clutch and allowing the engine to spin down when upshifting, or blipping the throttle to speed it up when downshifting.

This process is called double clutching, because it involves pressing the clutch twice: once to shift into neutral, then again to shift into the selected gear. However, this only applies to transmissions which are unsynchronized from the outset; it won't prevent a damaged synchronized transmission from jumping out of gear, for instance.

In those cases, it's likely a worn-out brass alloy ring. Going back to the meshing teeth principle, think of how difficult it would be to perfectly align a worn-down, flattened tooth, as opposed to a pointed one with a rounded tip. Furthermore, these components all experience tremendous pressure caused by friction, which means heat and metal-on-metal contact. As with any complex automotive component involving such forces, there are various means by which a synchronizer can fail, but most typically don't until well into a car's service life, as stated before.

The biggest culprit here is friction temperature, which may be caused by working the transmission too hard. This pushes the metal beyond its operating limit, causing a crashing noise, which makes it difficult to shift. Therefore, synchronizer preservation simply relies upon doing the maintenance and not mishandling a transmission.