How Powerful Is The World's Largest Piston Engine And What Is It Used For?

Picture a large-displacement piston engine in your mind. Perhaps the first image to come up is an engine you'd see in construction equipment, like the 20-cylinder quad-turbo 106-liter powerplant from a Caterpillar 797F mining truck. That engine powers a truck capable of carrying up to 400 tons up quarry hills, with torque figures that put even the most powerful big rigs to shame. And it produces 4,000 gross hp on top of all that, about twice as powerful as many of the world's most powerful hypercars. Well, the engine we're showcasing here is approximately 27 times more powerful than that, and it rests in the bellies of some of the highest-tonnage self-propelled objects ever built. It's the Wärtsilä RT-Flex96C inline-14 cylinder, the largest and most powerful piston engine on Earth.

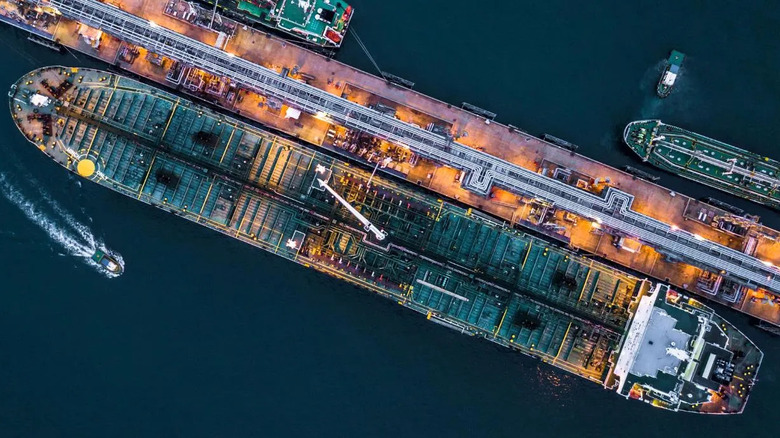

Measuring the horsepower of this giant is tricky. Initially, it was rated at "just" 108,920 hp at 102 rpm, though modern brochures list it at 114,800 hp at 102 rpm. This massive powerplant doesn't sit inside an engine room so much as it is within an engine hangar. When installed, the RT-Flex measures more than four stories tall and reaches a maximum of 120 RPM, acting as the beating heart of the vessels it powers. The Wärtsilä inline-14 primarily propels ultra-large cargo ships and tankers, with its maiden deployment in 2006 being aboard the Emma Mærsk, a vessel capable of transporting 11,000 20-foot cargo containers roughly 50% faster than comparable ships of its time. Let's explore the cavernous depths of this incredible marvel of engineering that has literal rooms inside the engine block.

Technical breakdown of the largest engine ever created

As mentioned before, this two-stroke diesel engine produces roughly 110,000 horsepower at 102 rpm; plugging those numbers into a torque calculator results in a monstrous 5,663,921 lb-ft of torque, which requires approximately 6,400 liters of fuel per hour in high-efficiency mode. The engine also weighs 2,300 tons, which is a massive chunk of weight. But let's shrink it down to size and put it up against an automotive engine to see how efficient it is.

Let's use a Cummins diesel, a fairly common engine powering several pickup trucks. The 6.7-liter found in Ram Trucks weighs 1,070 pounds and produces up to 1,075 lb-ft of torque, so about one lb-ft of torque per pound of weight. The Wärtsilä engine, on the other hand, weighs roughly 4.6 million pounds and generates over 5.6 million lb-ft of torque, making for about 20% more torque per pound than a Cummins.

The proportions of this machine are frankly difficult to comprehend. The crankshaft alone is as tall as the engineers that service it, installed in two seven-cylinder units back-to-back. The engine stroke is a whopping 98.43 inches with a 37.8-inch bore; at bottom-dead center, the average man could quite comfortably stand up inside the combustion chamber. In fact, there are numbered service doors leading inside each cylinder's housing for maintenance. All that said, it still functions like any other two-stroke diesel, effectively being just a regular engine scaled up by a factor of approximately 1,000.

Why shipping companies need the Wärtsilä engine

Ultimately, shipping companies, like all businesses, rely on money to stay solvent, and fuel costs add up quickly when engines require thousands of liters per hour. Consequently, Wärtsilä engineered these power plants to be, first and foremost, as efficient as possible, utilizing multiple advanced systems to further this goal. These include, but aren't limited to: a selective catalytic reduction system that reduces nitrogen oxide pollutants by 95%; twin common-rail fuel injection, one per seven-cylinder bank; a waste heat recovery system; and advanced turbochargers with scavenge air receivers. This allows RT-Flex96C-equipped vessels to not only be faster but also more fuel-efficient and less polluting than other ships.

Take aircraft engines, for example. One of the main reasons many operators no longer fly the Boeing 747 is the inefficiency of its four-engine arrangement compared to more modern airliners with larger twin-engine powerplants. That's why, for instance, General Electric developed the world's largest aircraft jet engine, the General Electric GE9X, to be more powerful and efficient than older jet engines.

Ships face similar struggles because, ultimately, the faster and less expensive it is to ship goods and services, the happier the customers will be. A larger engine will generally be more efficient than multiple smaller engines. A single, large engine requires fewer personnel; has less friction due to fewer working parts, resulting in better thermal efficiency and fewer parasitic losses; and costs less to maintain. Thus, such a system is quite appealing to shipping companies dealing with ultra-large capacities.