What Does DI-D Stand For On Mitsubishi Engines, And How Does The Engine Tech Work?

The once-almighty Mitsubishi Motors may have relegated themselves to building cheap small cars and Nissan-derived crossovers, but it was an indomitable powerhouse of innovation back in the day. Mitsubishi unveiled the world's first turbo diesel engine in 1980, and it launched the Pajero, aka the Shogun, in 1999 with the brand's first DI-D engine. DI-D stands for Direct-Injection Diesel, and Mitsubishi engineers derived the initial engineering blueprints of DI-D from the automaker's indirect injection (IDI) diesel mills. Mitsubishi DI-D engines are four-cylinder diesel engines with displacements ranging from 1.9 to 3.2 liters, featuring either aluminum or cast-iron blocks and aluminum cylinder heads.

The first Mitsubishi DI-D engine in the Pajero featured a distributor-type mechanical fuel pump, which distributes high-pressure diesel fuel directly into the combustion chamber via injectors. Unlike indirect injection (IDI), which injects fuel into a separate pre-chamber before complete combustion occurs in the cylinders, DI-D engines deliver greater control over fuel delivery, resulting in improved efficiency, better fuel economy, lower emissions, and enhanced performance. Mitsubishi DI-D engines like the 4D56 turbocharged direct-injected mill earned a reputation for being the most reliable from the brand while producing ample power and torque,

However, Mitsubishi was not the first to design a direct-injected diesel engine. Rudolf Diesel patented air-blast injection in 1893, and Maschinenfabrik Augsburg-Nürnberg, or M.A.N., became the first to develop a commercially viable four-cylinder diesel engine with direct injection. The technology allowed diesel engines to be compact and lighter, making them feasible for motor vehicles. Early diesel engines with air-blast injection were massive, cumbersome, and required equally heavy compressed-air tanks to operate, making them only suitable for stationary applications.

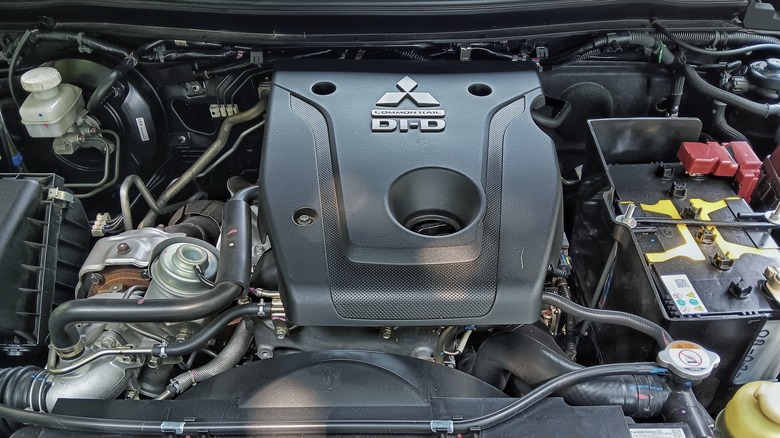

Mitsubishi Common Rail DI-D: Making diesel engines better

The Mitsubishi DI-D engine later adopted common-rail direct injection. The primary difference between DI-D and CRDI is the fuel delivery system. The former employs a mechanical fuel pump to deliver fuel to the injectors. On the other hand, CRDI uses a high-pressure fuel pump to pressurize the fuel and route it to the so-called common rail that functions as a reservoir and pressure accumulator. However, the fuel injectors in a CRDI diesel engine work in conjunction with the fuel pump to control the amount of fuel injected, along with the timing of the injection. An ECU governs the many settings of a diesel engine with CRDI technology.

Since CRDI diesels offer electronically controlled fuel injection, they offer many distinct upgrades over a DI-D engine. For starters, CRDI diesels are more responsive to throttle inputs, could produce more power and torque, deliver better fuel economy, and have lower emissions. The most desirable attribute is a night-and-day improvement in NVH, making CRDI diesel engines almost as quiet, smooth, and refined as gasoline engines.