Do Rotary Engines Need Oil Changes?

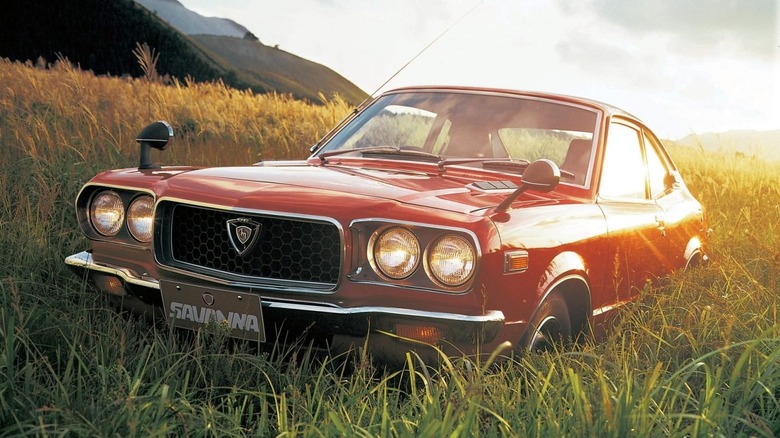

Wankel rotary engines, typically but not exclusively found in Mazdas, certainly lean on the "quirkier" side of modern powertrain systems, made quirkier because most rotary-powered cars on the road today are at least 10 years old. The final car to feature a true rotary powerplant was the RX-8, which Mazda was forced to discontinue for the 2012 model year due to poor sales figures. But regardless of how old they are, rotary engines feature reciprocating metal components, and those will generate tremendous heat and friction if not properly lubricated, like any other internal combustion engine.

In short, yes, a Wankel rotary does, in fact, need oil changes, and they typically need them more frequently than the average car. For instance, most sources recommend oil changes every 2,000 – 3,000 miles in a typical 1990s Mazda RX-7, with 5,000 miles being on the extreme high-end if you're lucky. As for what weight of oil, that depends on who you ask, with different owners using different weights depending on the application, climate, the specific engine model, and so on. However, they typically hover around the thicker side, ranging from 10W-30 to 20W-50, with lighter weights like 5W-20 not recommended today.

A modern RX-7's owner's manual recommends a viscosity of 5W-30 for winter and 10W-30 for summer. However, owners today typically opt for heavier oils, ranging from 10W-30 for winter to 10W-40 for summer, and even thicker oils for motorsports and high mileage. Let's discuss more about how a rotary works and the role oil plays in its operation.

Oil is the lifeblood of the Wankel rotary

The reason why oil is so important to Wankel rotaries relates to how a rotary engine works, and by extension, the principles of metal-on-metal friction. Modern engine oil is designed to lubricate components by creating a thin film between anything metal, including pistons, valves, camshafts, and crankshafts, and so on. Everything that rotates or reciprocates inside an engine has the possibility of building up heat and damaging internals if not properly lubricated, which will eventually cause an engine to outright seize if left unattended.

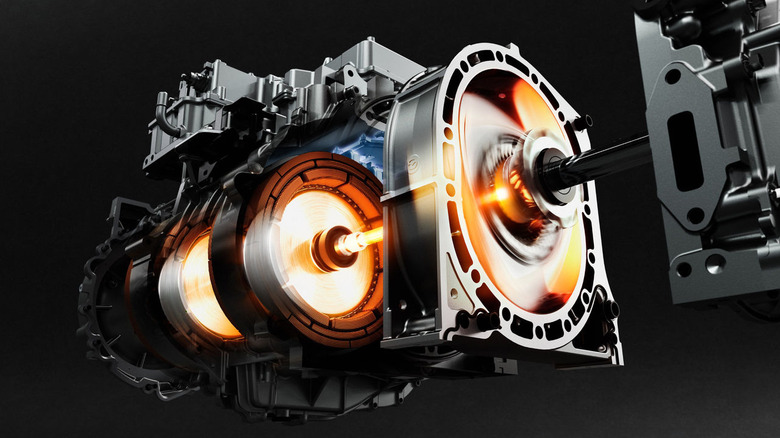

Wankels are more unique than most, with engine oil serving multiple functions inside one. First and foremost, rotaries still use oil as a metal-on-metal lubricant like any other internal combustion engine. They utilize a single crankshaft with eccentric lobes on it, and nearly every large internal component connected to it spins at thousands of RPM during normal driving. Not only does that put immense stress on the bearing surfaces, but also the housing side seals and apex seals. In fact, these seals alone account for a 10% loss in power efficiency in the average Wankel.

Without oil, these surfaces would create immense amounts of friction because there's no cushion; think of it like trying to run a marathon but with your knees having no synovial fluid, so it's just bone-on-bone. As such, maintaining the correct oil levels, viscosity, and filtration is crucial. Not just because of the typical passive lubrication, but also because of its second function: oil injection.

How a Wankel uses oil differently than a piston engine

This relates to the apex seal, its function, and its location. An apex seal is a physical plate that goes on the tips of the triangle, which segregates each step of the combustion process from one another by providing a vacuum seal. By necessity, apex seals must remain in contact with the rotor housing itself to remain airtight, otherwise it'll lose compression when air leaks out, like poking a hole in a pressurized hose. This is a friction-intensive operation because the apex seals themselves move extremely quickly when the engine's running. Much like how a power drill smokes when drilling into a block of wood, this heat can quickly build up if there's no lubrication.

To lubricate an apex seal directly, the oil must be spread evenly across the entire outer surface of the housing. As such, a typical Wankel will actually inject oil directly into the intake chamber where it lubricates the seals. Each seal picks up oil at the intake rotation, creating a film coating the edge of the seal and the housing itself. By necessity, this also makes rotary engines oil burners, though it's not necessary to premix your rotary engine's fuel with oil, unlike a two-stroke engine. Instead, a rotary engine uses dedicated oil nozzles in the intake manifold.

This is also why you should only use conventional mineral oil in rotary engines; synthetic oil creates harmful deposits in the combustion chambers and doesn't lubricate the rotor's rubber O-ring seals properly, resulting in fouling and damage to the engine's internals. Similarly, it's why Wankels prefer heavier weights. Thinner oils cannot maintain adequate oil pressure.