Why Do Rotary Engines Make That Unique 'Brap Brap' Sound?

The Wankel rotary engine offers one of the most unique sounds of any ICE. Most famously used in various legendary Mazdas like the RX-7 and the supposedly banned Le Mans-winning 787B race car, the trademark of this engine rests in that signature brap-brap note. But why does the engine produce that noise at all, especially considering it rotates instead of reciprocates like a normal piston engine? Shouldn't it make a humming note instead? The reason why relates to how the engine actually works, so let's break it down piece by piece.

In short, factory Wankel engines don't make the brap-brap noise at idle, they make a constant low hum like an inline-six. That's because the individual notes a person hears are explosions occurring inside of an engine, modified by the exhaust gases as they exit the combustion chamber and run through various elements like mufflers and catalytic converters. In a stock rotary engine, those notes are all uniform because, from the factory, the plates separating the rotors are solid and prevent gases from interacting between combustion chambers.

Porting is similar to if someone were to put a heavier cam into a typical piston engine. To create this sound, you need both the intake and exhaust valves open at the same time for a split second, allowing the exhaust gases to bleed over slightly into the intake.

In other words, the intake valve needs to be open for longer than normal, creating a gas overlap. The air pressure differential means the exhaust gases rush to the intake side as the car sucks in fresh air for combustion, modifying the exhaust note and creating the off-note brap sound.

How a Wankel rotary produces its signature sound

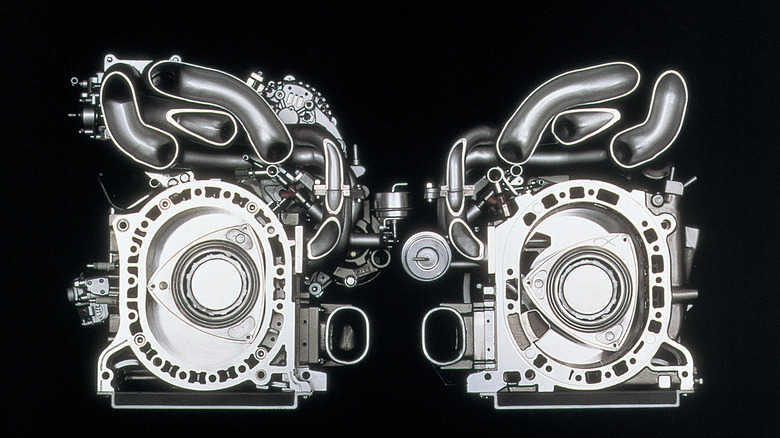

All this ties into the fundamental principles behind how Wankel rotary engines work. The common rotary is, essentially, a triangle spinning inside of an eccentric housing on an off-axis rotation. Here's a video to get familiar with the inner workings, for the visual learners.

Much like any other combustion engine, a Wankel rotary draws air into the combustion chamber via vacuum pressure. As the rotor spins, the sealed environment will expand and pull air in like sucking on a straw. This air then compresses, is ignited, and expands at the end of the rotation cycle. The rotor then compresses again, pushing the exhaust gases out like a moving wall. Then, as it rotates back to the intake stage, the cycle begins again.

Typically, a rotary engine sounds smooth because all of these individual processes are sealed from one another from the factory. Much like running a hotter camshaft, modifying the valvetrain to give that brap sound makes the engine run rough at idle, and that's because you're modifying the amount of air and how fast it's being sucked into and out of the engine whenever a valve opens.

When you have a larger valve open for longer, the air will slow down due to the pressure differential, in the same way that blowing air with your mouth wide open results in a slower airspeed than blowing with your mouth partially closed. The factory accommodates for this phenomenon, tuning the car to run smoothly as a result, hence why Wankels typically hum from the factory.

Creating the brap sound

As mentioned before, getting the engine to brap involves letting some exhaust gas bleed into the incoming air on the intake stroke, essentially connecting the two halves for a calculated margin of time. In order to do this, the two halves must be joined at some point, similar to putting a hot cam into a piston engine which makes that burbly low-end valvetrain noise.

But, unlike camming a piston engine, this involves intricate machine work, where the mechanic must carefully drill holes into the housing body itself and modify the shape of the valves. Two main processes accomplish this.

One is called bridge porting, which modifies the housing face, while the other is a peripheral port, which alters the structure of the chamber walls. The difference between the two is where the air is introduced and extracted. On a bridge port, this process occurs on the sides, whereas on a peripheral port, it occurs in the center of the infamous apex seals. The basic concept stays the same, you're effectively adding new ports for additional airflow.

Bridge porting is often performed not just for the sound, but because it represents a functional performance boost in high RPM rotaries. The engine is able to accept more air when the rotor is spinning quicker when it has a bridge port, with the net result being that, the higher RPM, the more power you get. Not only does it push the rotary's peak horsepower and power curve higher on the RPM band, but it overall improves the raw horsepower number. More air in the chamber is more air to burn for meaningful power, after all.