How Automakers Have Borrowed Joinery From Traditional Japanese Woodworking

The cool thing about construction and engineering is that different spheres aren't always as isolated as you may expect. Some manner of construction technique originally conceived for houses, for example, could end up finding its way into the construction of cars — whether for aesthetic or practical purposes. These kinds of design fusions can lead to fascinating, novel concepts that you may not have ever thought of previously.

Case in point with architectural joinery: Joinery is a technique often used in woodworking, wherein wooden components are specially-shaped to interlock with one another and form a sturdy constitution, all without using any kind of additional fasteners. You can see examples of woodworking joinery all over the world, but the joinery used in Japanese woodworking is particularly interesting for both the near absence of metal components, and the remarkable sturdiness of the final structure.

Several Japanese automotive brands like Nissan and Toyota have taken notes from its national roots over the years in the creation of various concept cars. These inspirations have resulted in one-of-a-kind vehicles with a traditional architectural touch, utilizing wood in more artistic ways than the simple wood panel vehicles you may be familiar with.

Japanese joinery fits wooden components together with no metal fasteners

In past eras, American and European countries had readily accessible iron of a reasonably high quality, so they could produce a consistent supply of iron nails for fastening wooden constructs together. Japan, however, didn't have access to that high-quality iron, so nails weren't really an option. To compensate, woodworkers would use joinery techniques, cutting and carving thick and resilient wood into interlocking blocks, beams, panels, and more.

Two of the benefits of Japanese woodworking most clearly are seen in furniture production and architecture. If you visit one of the country's many traditional temples, shrines, or castles, you can look up into the rafters to see the interlocking wooden beams holding everything together. Despite the absence of metal fasteners, the sturdy wood and joinery techniques employed by master craftsmen have allowed these structures to endure through the ages.

Japanese joinery has both practical and aesthetic applications, representing an intersection of large-scale carpentry and small-scale woodworking. The simpler materials mean that structures are easier to repair if necessary, and their freely-flexing designs shore them up against the country's more frequent earthquakes. These are factors this classic form of architecture has in common with even modern building techniques like 3D printing. Traditional joinery also has roots in the Shinto faith, with the practice meant to show more respect to the wood you work with, rather than covering it up with metal.

Brands like Nissan and Toyota have utilized joinery to various degrees

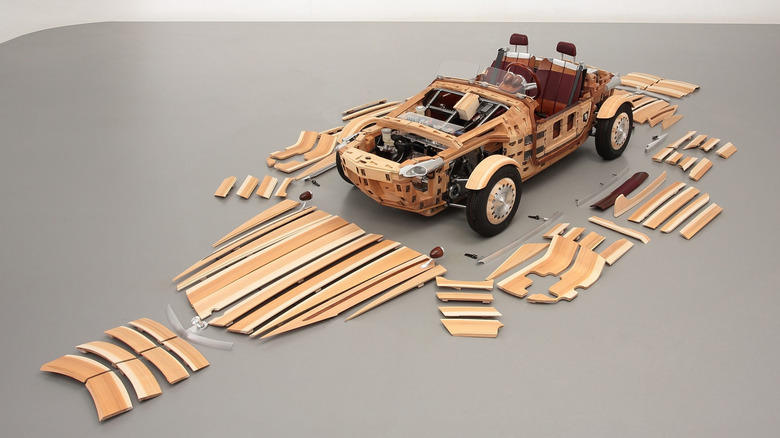

Over the years, several Japanese automotive brands like Nissan and Toyota have incorporated the tenets of traditional joinery into the construction of various concept cars. While nothing commercially-drivable has been produced, these concept cars showcase both the individual automakers ingenuity, and the stylistic potential of wood in the automotive scene.

In 2018, Nissan debuted its XMotion concept car at the North American International Auto Show, a brawny-looking vehicle with a soft and calming interior. One of the major highlights of that interior was the center console, crafted from smooth cedar wood, and installed using traditional joinery techniques. The joined wood makes the console look almost like a strong spine running through the car's center. Nissan incorporated joinery techniques again in 2019 with the IMk electric car concept, which featured rows of wooden slats interlocking with the lower door sections. These slats are a nod to the joinery concept of kigumi, with every slat individually carved by hand.

Further back, in 2016, Toyota went positively wild with the concept of joinery for Milan Design Week in the form of the Setsuna concept car, a roadster crafted almost entirely from wood. All of the vehicle's external panels are made of wood, with interlocking components beneath the surface fastening them to the body. Toyota consulted seasoned woodworkers with experience in temples and ships to put the Setsuna together, all with the intent of conceptualizing a vehicle that could endure through the ages like a beloved family heirloom.