Which Planes Did Ford Make During WW2 And How Many Did It Manufacture?

The industrial might of the American economy during World War II earned its reputation though hard work, innovation, and a continuous chain of millions of personnel, vehicles, aircraft, equipment, and more. But these materials didn't appear out of thin air; someone had to manufacture it all. That job fell to various industrial companies across the country, with Ford contributing significant portions of their own infrastructure exclusively to wartime development and production. Ford produced everything from Jeeps, tanks, infrastructure, even pulsejet engines for early cruise missile designs, across various facilities temporarily ceasing automotive production in the process. Ford's aircraft represented one of its most crucial exports: namely, the Consolidated B-24 Liberator bomber.

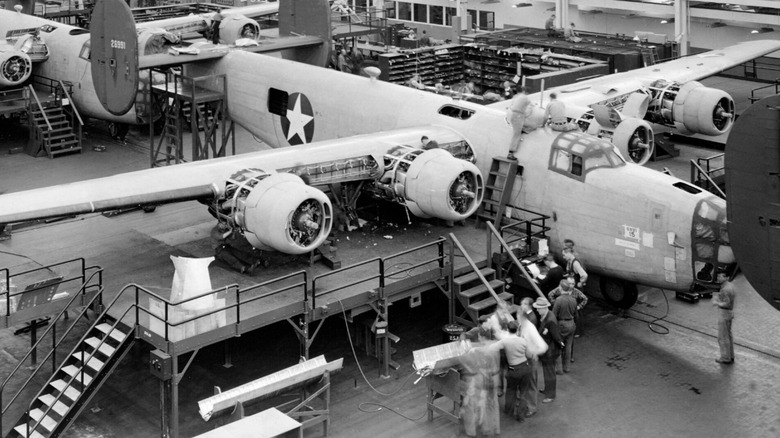

Housing its central production facility in the Willow Run Bomber Plant, Ford produced a combined total of 8,685 B-24 Liberators, with production running from May 15, 1942 to June 28, 1945. This number includes 6,792 complete airframes in addition to 1,893 "knock-down kits". A knock-down kit is comprised of all the parts required to build a complete bomber, which Ford shipped to either Fort Worth or Tulsa for final assembly.

The B-24 Liberator was produced in larger numbers than any other American aircraft of the Second World War, with three companies running five factories to service the production quota. In total, over 18,000 Liberators left these plants, with almost half belonging to Willow Run.

Let's dive deeper into the production history of this venerable warbird and the Willow Run plant itself, as its story inexorably ties with the Liberator's early development.

Tooling up for war

Ford commenced construction of the Willow Run plant in March 1941, following a request from the U.S. government to prepare for the manufacturing of military equipment prior to their official entry in the war. Early research revealed the necessity for an enclosed facility where parts wouldn't be exposed to the fluctuating temperatures of the outdoors, warping components during construction. Ford utilized their expertise in automotive mass-production to set up similar facilities for aircraft, constructing 11 assembly lines and 69 sub-assemblies for various stages of the production process. With many young white men serving, The Willow Run plant's employees consisted of a notably diverse group of people, including African Americans and workers too old to serve. Over 15,000 of all its employees were women, representing approximately 35 percent of Willow Run's total complement of over 42,000. One of these women, Rose Will Monroe, achieved international fame as the figurehead of the "Rosie the Riveter" poster.

Despite these advanced facilities and formidable workforce, early examples of B-24 Liberators suffered from numerous teething issues. The government's constant design changes, coupled with the automotive-based production methods, caused significant delays and reworks, prompting numerous visits from high-ranking officials and line retooling. Ultimately, Willow Run only assembled 56 complete airframes in 1942, a far cry from the expected turnout of one per hour.

Things quickly turned around in 1943, however, with the final quota steadily up over the course of the year, starting from 37 planes in January to completing the 1,000th finished airframe in November.

The B-24's success

Originally designed as a flying boat (hence its large, boxy fuselage), the B-24 Liberator represented a dramatic technological leap forward against the outdated but equally-influential Boeing B-17 Flying Fortress. For instance, the B-24 incorporated hydraulically-actuated components such as landing gear and flaps, whereas the B-17 was all-electric. As such, a variety of the B-24's systems proved more robust, reliable, inexpensive, and easily-maintained by comparison.

This trend extends over most of the B-24's airframe, resulting in marked improvements over the B-17 in terms of range, payload capacity, and speed, though the B-17 outmaneuvered and boasted a higher service ceiling than the B-24. The British Royal Air Force in particular enjoyed its additional payload, utilizing Liberators as their heavy bomber of choice since it entered RAF service in 1941. In the B-24D configuration, the aircraft carried 8,000 pounds of bombs at 303 miles per hour at cruise, with a maximum range of 2,850 miles. Each B-24D cost $336,000, about $100,000 more expensive than a B-17G.

Overall, the B-24 suffered substantial losses throughout the war, with anti-aircraft batteries and higher-flying interceptors like the Focke-Wulf 190 and other exceptional German planes tallying significant portions of entire formations. However, the United States war economy easily outpaced anything the Axis could retaliate with. As such, the sheer production numbers proved instrumental to the success of both the European and Pacific campaigns. By war's end, the service record of the Consolidated B-24 propelled the aircraft to become a symbol of the United States industrial machine's might.