10 Tools & Supplies You'll Need Before Starting An Engine Rebuild

Whether to rejuvenate a broken down car or to upgrade and increase the power output, rebuilding an engine is a major job. It takes a great deal of mechanical skill and knowledge to undertake such a procedure, and preparedness is paramount to a successful outcome. Keep in mind that all the work being done is not just to get an engine running again, but to get it running for upwards of 200,000 miles, although racing engine builds are an exception to that rule.

While you need to attain a wealth of information about the process of tear down and rebuild as well as sourcing parts and determining what can be reused and what might need to be resurfaced by a machine shop, you will need a wide range of tools, including many specific for the job. By the time most people are ready to jump into an engine rebuild, at least some of the specialty tools will likely be in their toolbox already. However, some tools are used only during a rebuild while others are large and expensive, meaning rental tools is a good option. I rebuilt my first engine as a project for an auto repair class in tech school. Fortunately for me, the school provided all the tools needed. However, if you plan to revive your car's power, I recommend locating these tools before starting the job.

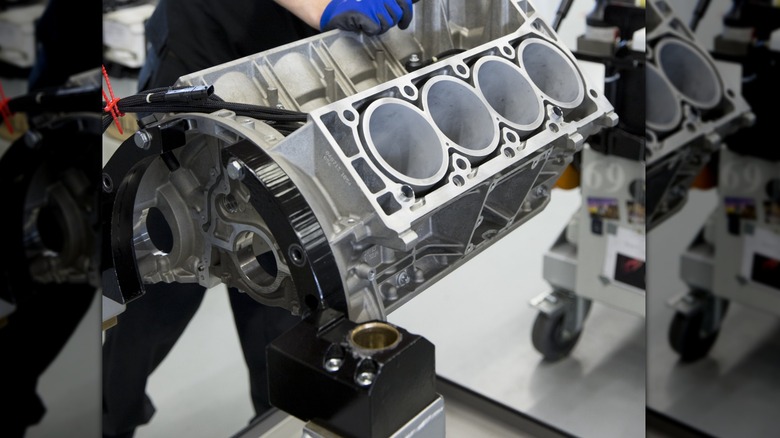

Engine stand

It should be a given that a stand to hold the engine during the process will be needed. However, there are different types of stands available for a range of prices. What they all have in common is a high weight capacity and the ability to turn the engine to allow the installation of various components as the build progresses. You will want to have it rotated 180 degrees after installing the crankshaft when it's time for the pistons to go in from the top.

Harbor Freight engine stands represent good value for money. A basic stand will handle engines from most passenger cars and rotate the block for about $100. With an increased budget, you can have a folding stand for convenient storage or a 1,500-pound capacity stand with crank handle rotation, a requirement for rebuilding heavy-duty diesel engines. Summit Racing and Jeg's High Performance also offer good choices, and your local parts store almost certainly can order one for you.

Engine hoist

Before the engine rebuilding can begin, it must first be removed from the vehicle. For most cars, that means using an engine hoist, also known as a "cherry picker" or crane. Some cars are built in such a way that it is actually easier to drop the engine down through the bottom of the engine compartment. A hoist can also help to suspend it as it is readied to be lowered onto a cart, but may not be needed with the right kind of jack on which to lower it.

Engine hoists tend to be relatively large. Unless you plan to perform multiple engine rebuilds or start a side hustle dropping new engines into your friend's whips, renting a hoist may be a better option. Harbor Freight offers a range of engine cranes, but with pricing starting near $300, you can see why a rental might be worth looking into.

Once your engine is fully disconnected from every part of the car, pulling it out with a hoist is easy. Once removed from the car, the engine can be installed onto your stand and the hoist will not be needed again until installation. Most major equipment rental businesses offer hoists as well, and they are probably better than what you can buy for $300. Additionally, these will probably be a towable unit with a hitch and wheels for easy transport. Prices can vary widely by location, so you call around for the best deal near you.

Torque wrench

When assembling an engine with a block that has been properly prepped by a machine shop and all new parts, it must be completed properly. Of course, a variety of specialty tools will be required to assemble an entire engine, but none are likely to be as crucial to have as a torque wrench. Without one of these, all the rest of the hard work will go to waste and probably in horrendous fashion.

When installing critical components of your engine such as the crankshaft and cylinder heads, the bolts will have a specific torque setting. They need to be tightened with a specific amount of force, no more and no less. A torque wrench measures that force, allowing you to apply the correct amount per specifications.

Old torque wrenches have a separate bar that shows on a marked gauge how much is being applied, letting you stop when the needle points to the correct reading. However, modern torque wrenches are much easier to use, allowing you to set the correct setting on the wrench, which will click when that amount of force has been achieved. Pricing is all over the place for these. A Snap-On can cost nearly $500, which may be a bit overpriced, while one from Harbor Freight can be had for $20.

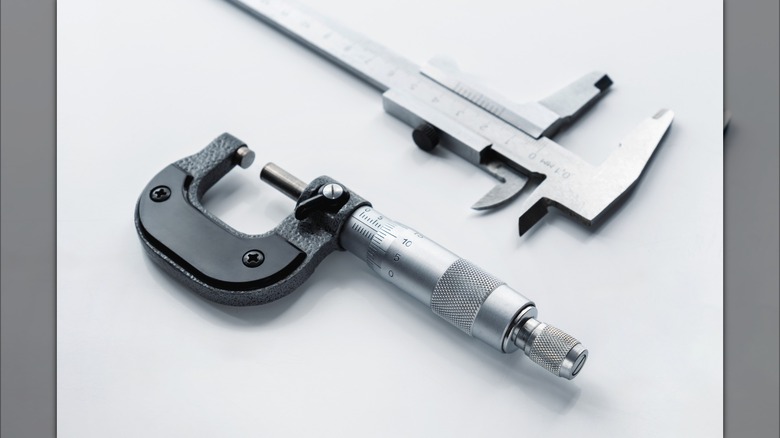

Micrometer set or Vernier caliper

Once you have an engine torn down to the block and its internal components are splayed on a workbench, you need to determine which parts can be reused, reconditioned, or replaced. Proceeding at this point requires precise measurements to discover which parts will still operate within acceptable tolerances. The rulers of choice are the micrometer or vernier caliper.

Origins of the micrometer lie in the late 17th Century, and the tool made it possible for the first time to create things using extraordinarily precise measurements, making its adoption one of the most important developments of the industrial revolution. A micrometer measures with precision to within thousandths of an inch. Alternatively, a Vernier caliper can be used to take the same precision measurements, although with less accuracy.

Engineering tolerances specify how tightly various internal components within the engine must fit. Whether you can reuse a part, recondition it, or replace it will be determined by precise measurements. If they are out of the acceptable range, a part cannot be reused as-is. Failure to adhere to specifications may result in engine failure or, at a minimum, a severely shortened lifespan.

Impact wrench

One of the headaches of the engine rebuilding process lies in removing bolts of an engine that have been in place for over 100,000 miles and possibly a decade or two. This can be complicated further by rust, particularly the north the car resides. To speed the process of disassembly, you need an impact wrench.

Impact wrenches today are available as pneumatic or electric, with both wired and cordless versions available. They are generally built with a gun-like shape and help to loosen or tighten fasteners with high torque both by using reduction gears or increased torque as well as a hammering mechanism. They provide the effect of using continuous high-powered blows to help break a bolt free.

Pricing of impact wrenches varies widely depending on brand, size, and power source. Pneumatic versions have long been a staple of any professional auto repair shop, but electric versions have become much more common over the last 10 to 15 years. In that time, battery-powered cordless impact wrenches have become highly popular and are offered by every major brand. In my experience using tools like these, you get what you pay for, and having a tool with more power that will last longer is definitely worth the extra expense.

Hand tools

It should be a given that hand tools are required when rebuilding an engine. However, a basic set of flimsy tools your Grandma bought for you from TG&Y in 1988 will not do. With the variety of fasteners small and large used in engine manufacturing, a full complement of tools is a necessity.

While a double refrigerator-sized toolbox full of Snap-On tool sets or MAC tools is overkill for a personal engine rebuild project, you should have more than strictly the basics. Having a good variety of shallow and deep well sockets with ratchets in ¼-, ⅜-, and ½-inch drive on hand will just get things started. Various screwdrivers, wrenches, hammers, mallets, and pry bars will all come in handy along with internal and external hex sockets and Torx bits, especially when working on European vehicles.

Only if you are working on a classic American car made before the 1980s will you be able to forgo having any metric tools on hand. Conversely, American cars made since the early 1990s will have almost exclusively metric fasteners. It is also important to note that these are general guides based on my experience, and the use of imperial and metric fasteners evolved over the years on all cars at different times.

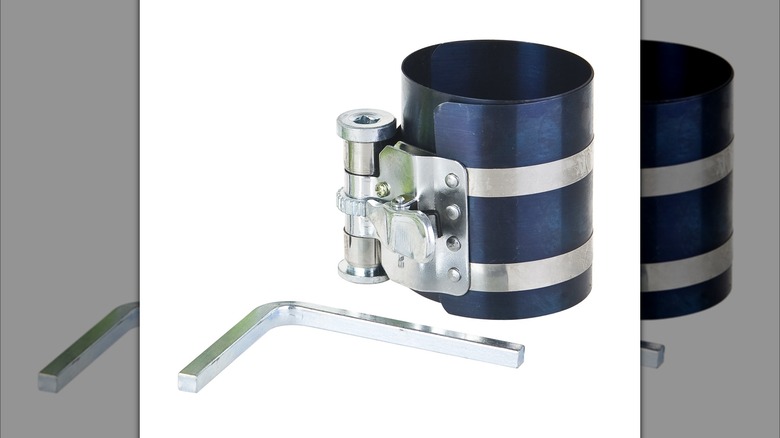

Piston ring compressor

If you have a fundamental grasp of how an engine works, you already know that the piston rings rest directly against the cylinder walls and must keep a tight seal to enable compression of the air and fuel charge. However, if you have seen a piston with rings installed, you might have noted how the rings are a bit wilder than the piston itself. This is why you need a ring compressor, a crucial tool for the job.

The compressor is a relatively simple tool only used for this one operation during engine assembly. Most ring compressors are made of a sheet of this steel rolled into a cylinder shape that can be manipulated to give it a smaller diameter. This is placed over a piston with the rings and crankshaft already installed. You have to use it to compress the springs into the grooves on the piston and hold it tight enough that the piston can be gently knocked down into a lubricated cylinder. Once you have done that for all four, six, or eight cylinders, you can put it back into your toolbox until the next engine assembly comes around.

Cylinder hone

For many engine rebuilds, the block is sent off to a machine shop to have its surfaces refinished and brought to a like-new condition ready for new parts. However, this is not always the case nor is it always necessary. For some jobs, which may include small engines like a single cylinder motorcycle block, a complete resurfacing can be skipped. However, honing the cylinder is a must.

Cylinder hones come in two forms. The first is a flexible metal shaft generally about 12 to 15 inches long with an array of abrasive little balls arranged in a cylindrical shape. They come in a variety of sizes to fit various different engines and are operated using a drill. The second also has a flexible shaft but comes with three stones arranged to be held with spring tension against the inside of a cylinder. These stones are made of a similar material to what is used for sharpening knives.

The purpose of the hone is to prepare the cylinder for seating the new piston rings. To form a perfect seal, the ring and cylinder have to have as close a fit as possible. To attain this, cylinder walls should have a slightly rough surface that will become perfectly shaped to the ring during the break-in process. The small amount of abrasion that happens in the first few hundreds miles will cause just enough wear material to form a complete seal. A well-honed cylinder is crucial to a well-built engine.

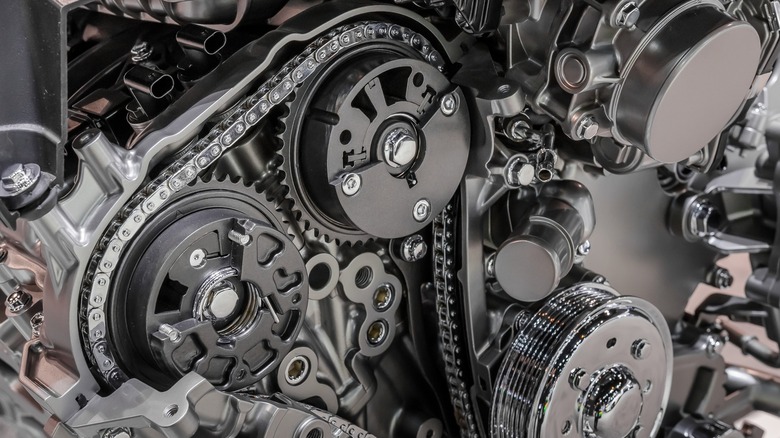

Valvetrain specialty tools

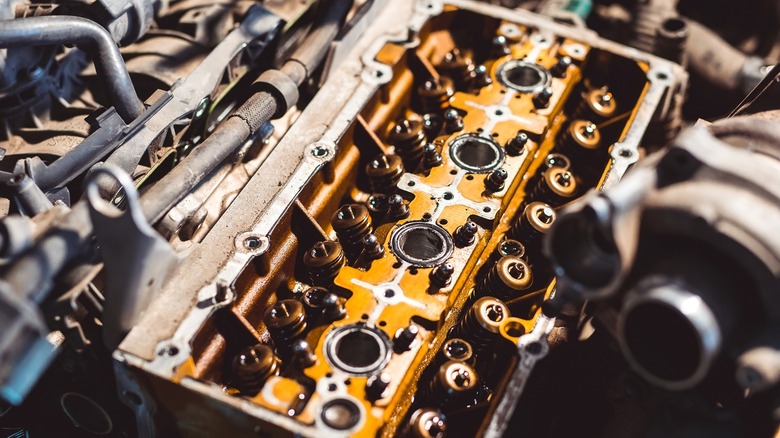

One of the most delicate operations of the engine rebuild process has to do with the valves. On four-stroke engines, the engineering to make the valves operate in the optimum manner is incredibly complex and sophisticated, making a perfect assembly of the entire system critical. While modern features such as variable valve timing have been the most effective fuel efficiency technologies, they increase the complexity as well as the various tools required for the job.

The list of tools can be lengthy and differ from engine to engine. Some kind of valve spring compressor will be necessary on all engines along with valve guide tools and probably one to help with the valve retainers, also known as keepers. Otherwise, you may need a tool for cam phasers on a Ford Triton engine while something completely different will aid in assembly of a BMW VANOS system. Other engines require specific tools for installing the timing chain or belt and ensuring everything is lined up perfectly and in time.

Creating a list of these tools could be never ending. The important takeaway is to research your engine and figure out what specific tools you will need well in advance of beginning the job. That will save you from inevitable headaches later on.

Cleaning tools and supplies

When endeavoring to rebuild an engine, a lot of cleaning will be in order. Engines can get dirty, especially those due for a rebuild. Be prepared to tackle a lot of grime and grease and have a place suitable for such work.

Early in the process, a variety of brushes of both wire and nylon bristles are useful to scrape the thickest of sludge on the exterior of the engine, while degreaser and a power washer can finish the job. During the disassembly process, ample amounts of brake cleaner are useful to clean individual components before being set aside until time to re-install them. Furthermore, for some smaller parts that get grime dug into every little crease or crack, a bead blaster is handy to remove every foreign particle to bring it back to like-new condition.

Having every part as clean as possible when assembling the engine is important to prevent contaminants from getting inside the engine and slowly destroying it from within. It also ensures that all your gaskets and seals will not leak. Additionally, keep your workspace clean to ensure your engine rebuilding project is a success.