8 Of The Most Effective Fuel Efficiency Technologies Ever Made

While EVs have become the go-to choice for drivers looking to cut their carbon emissions, modern combustion engines are also more efficient than ever. This isn't by accident — it's the result of increasingly stringent rules on tailpipe emissions in key car markets around the world. They've forced manufacturers to employ a number of new technologies to make their car engines greener, with the added bonus of saving drivers money at the gas pump.

Many new cars come with multiple types of fuel-saving technology which, when used together, can lead to overall fuel savings of 10% or more. However, not all of them are particularly noticeable when driving every day. In fact, some drivers might not even be aware that their car has one or more of these systems fitted. Although the rules are likely to get even tougher as more countries legislate net-zero emissions targets, these eight efficiency technologies are helping to keep new combustion engine cars in dealerships for the foreseeable future.

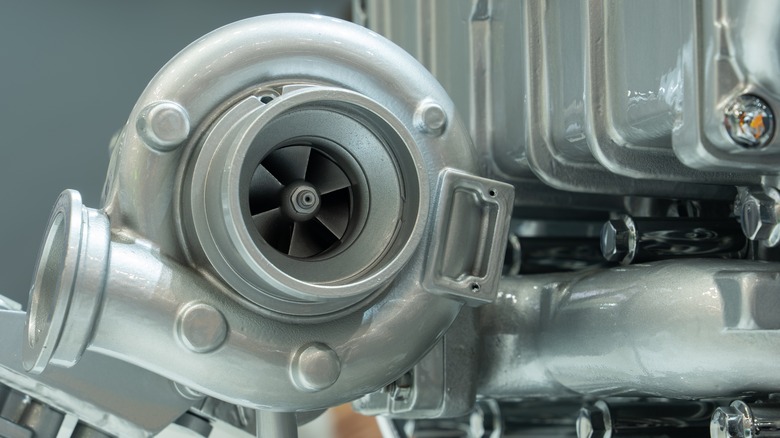

Turbochargers

One of the most common fuel-saving technologies to see on a modern car is a turbocharger. They allow manufacturers to shrink the size of an engine without compromising on power by forcing high-pressure air into the combustion chambers. This high-pressure air contains a higher concentration of oxygen molecules, increasing the power of the combustion reaction. In turn, this means a smaller engine chamber is needed for the same amount of power to be generated overall.

Turbochargers rely on exhaust gasses to drive a turbine, which is connected via a shaft to a compressor wheel. This wheel draws in air and compresses it, before sending it into the engine. A constant flow of exhaust gas is needed to spin the turbine, which is then channeled out of the turbocharger through a separate outlet. Turbochargers were once the preserve of performance cars, but in recent years, even the most budget-oriented passenger cars have begun using them. That's because they're one of the most cost-effective ways to increase fuel efficiency — the EPA estimates an increase of up to 8% overall.

Stop-start technology

Another common feature of modern cars is stop-start technology, which stops the car's engine from running when the car is stationary, then starts it again when the driver presses the accelerator. The idea is to cut emissions when drivers are idling in traffic, especially in cities where long periods spent stationary are almost guaranteed for any morning commute. In order to prevent the additional starting and stopping from wearing out the starter motor, cars equipped with start-stop tech use tougher motors and components than those not equipped with the system. That means that the motor shouldn't wear out any faster than normal. It's worth noting, however, that turning the engine off manually in a car that doesn't have start-stop tech is actually worse for both fuel consumption and the car's starter motor, so it's not advisable.

Plenty of drivers choose to turn their car's auto start-stop feature off, as there's often a slight delay between pressing the accelerator pedal to restart the motor and the motor actually kicking in. The newest cars have refined the technology further so that the difference isn't as noticeable, but for slightly older cars, it'll take some getting used to for anyone switching from a car that doesn't have start-stop fitted. Still, it's worth getting to grips with, as the EPA says it increases efficiency by about 2%.

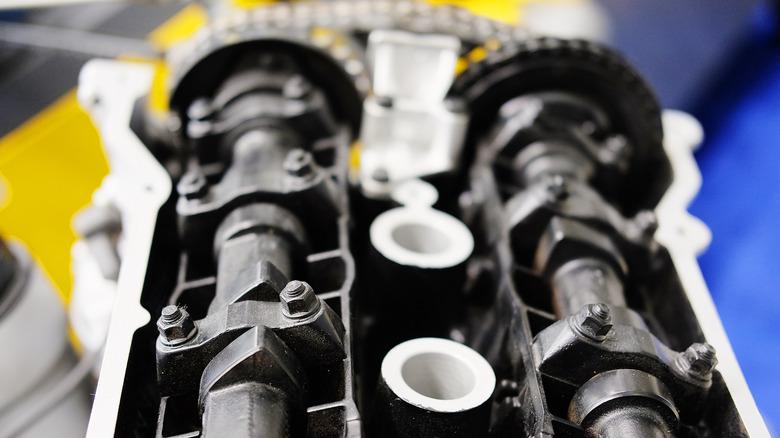

Variable valve timing

By changing when the intake and exhaust valves open during an engine's stroke cycle, a variable valve timing system alters the mix of gas and air that flows into the engine. This gives an engine a variety of profiles that can be switched between, depending on the driving speed and situation. Every manufacturer has a slightly different system for altering valve timing, but the basic principles remain the same. Being able to adjust the valve timing means that manufacturers can prioritize efficiency when the engine doesn't need to work as hard, but prioritize performance when it's needed.

Most manufacturers have their own names for their variable valve timing systems, with Honda referring to its system as VTEC and BMW calling it VANOS. No matter what they're called though, they all aim to perform the same basic function — increase efficiency without compromising on power. Research cited by the EPA notes an efficiency increase of three to four percent, although it's worth noting that the effectiveness of such a system will vary by manufacturer and engine type.

Continuously variable transmissions

Alongside the traditional automatic, another type of transmission is becoming increasingly common in modern cars: the CVT, or continuously variable transmission. A CVT does away with set gearing altogether, and instead features two cone-shaped pulleys that move closer and further away as the car changes speed. One pulley is connected to the engine, while the other is connected to the driveshaft, and the two are connected by a belt. This setup allows for a near-infinite number of gear ratios.

In theory, this means that the car is always in the optimal gear ratio for its speed, increasing efficiency by around 3-4% according to the EPA. However, there are a few downsides that put many buyers off having a CVT. Perhaps the biggest is the noise: CVTs are notably louder than regular automatics, both when accelerating and at a constant speed. They can also feel dull to drive, since there's no shifting taking place. To make matters worse, they don't tend to last as many miles as a traditional automatic transmissions, and can be expensive to replace when they do break.

They're not without their flaws then, but in recent years manufacturers have taken steps to address all of the above issues, and today's best CVTs are significantly improved over those in older cars. Like them or loathe them, they're notably more efficient than a regular automatic transmission, even with their flaws.

Mild hybrid systems

There are several different types of hybrid powertrain available on modern cars, each providing different levels of electrical assistance to a gas-powered motor. The mild hybrid, also known as the 48-volt hybrid, relies the least on its electric motor. A full hybrid or plug-in hybrid features an electric motor that's capable of driving the car under its sole power, but with a mild hybrid, the electric motor can only provide limited assistance to the combustion engine. That assistance is mostly called upon when the car is first taking off from stationary, providing a boost at stop lights or in traffic.

Each mild hybrid system varies by manufacturer — some are so mild that most drivers will barely notice they're there, whereas some perform more of an active role in low-speed acceleration. This, in turn, affects the efficiency of each system, although the EPA estimates that a mild hybrid improves efficiency by around 3-6% on average.

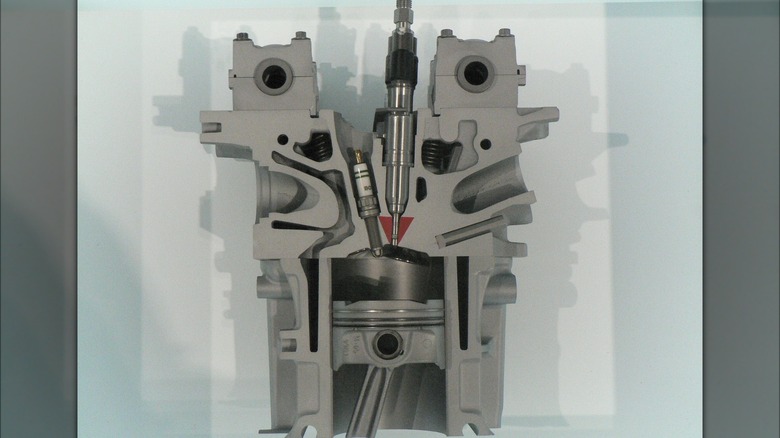

Gasoline direct injection

In a conventional gas engine, fuel is pushed into the engine through the intake port, where it mixes with air before entering the cylinder. Direct injection bypasses this step and injects the gasoline straight into the cylinder, through a dedicated injector that's fitted either into the wall or the top of the combustion chamber. If the injector is located in the chamber wall, a dome is added to the top of the piston to spray fuel in the direction of the spark plug. If it's fitted into the top of the chamber, it will spray evenly down throughout the chamber and so a conventionally shaped piston can be used.

Spraying the fuel directly into the chamber improves efficiency by around 1%, according to the EPA, and can also reduce turbo lag. However, like all the efficiency systems here, it does increase the overall complexity of the engine, which can lead to bigger repair bills in the event that something breaks in the future.

[Featured image by Ton1~commonswiki via Wikimedia Commons | Cropped and scaled | CC BY-SA 3.0]

Cylinder deactivation

While large V8 and V6 engines are great for performance, they're not as efficient as a smaller engine. Using cylinder deactivation, manufacturers try to have the best of both worlds, shutting down a number of cylinders when they're not needed to effectively turn a larger displacement engine into a smaller one. In most modern cars, these systems shut down half of the total cylinders, so a V8 becomes a four-cylinder, and a V6 becomes a three-cylinder.

This can have a notable effect on fuel consumption, with the EPA estimating that cars using cylinder deactivation are up to 5% more efficient. However, this figure will vary considerably by car model and driving situation — for drivers in stop-start traffic or regularly accelerating and slowing, the average savings are likely to be reduced. Likewise, a long highway drive at a steady speed is where the system is at its most effective.

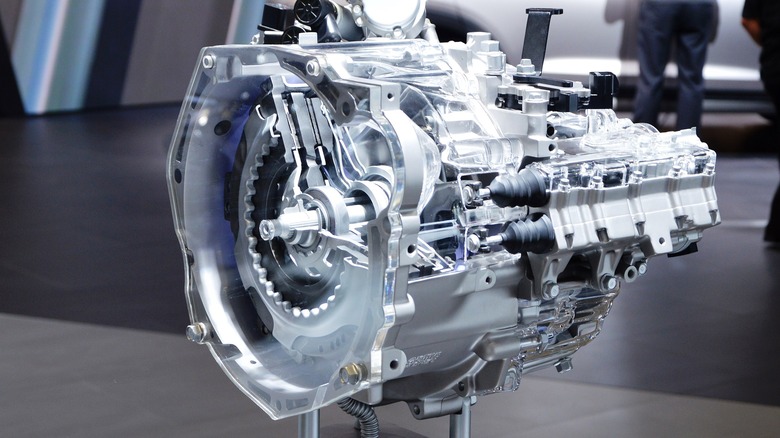

Dual-clutch transmissions

As well as conventional automatic transmissions and CVTs, another type of transmission has become more commonplace in recent years. Dual-clutch transmissions (DCTs) feature two separate clutches and can either shift autonomously or through driver input with paddles or a shifter. It first rose to prominence in motorsport and performance cars, but in recent years has begun to make its way into more everyday passenger cars.

One of the key reasons for this is that DCTs offer improved fuel economy over conventional automatics. They also offer faster shift times, for drivers looking for maximum performance potential out of their daily driver. However, there are some downsides: they're often not quite as smooth at low speeds as conventional automatic transmissions, and like any uncommon component, can be more costly to repair than conventional gearboxes. However, the increased efficiency alone might be enough to sway some buyers, as the EPA quotes a 3-4% advantage for cars equipped with the technology.

[Featured image by Spielvogel via Wikimedia Commons | Cropped and scaled | CC0 1.0]