This Revolutionary Launch System Sends Satellites Into Orbit Using Electricity

From pickup trucks to airplanes, the transportation sector is rapidly embracing electrification. But, as you might imagine, access to space remains the final frontier. The Earth's gravity is as strong as it is unrelenting. Since the dawn of, well, the space age, the only way to launch a payload into orbit was to strap it to the carefully calibrated bomb that is a rocket engine and hope that the massive chemical explosions remained controlled and kept to the desired trajectory. That's not stopping one company from reimagining — if not reinventing — the wheel to put their own spin on reaching orbit.

SpinLaunch is a private space technologies company founded in 2014 with the desire to lower the cost of reaching space while increasing launch frequency as compared to traditional rocket technology. This in itself was not entirely unique. SpaceX, for example, was founded 12 years prior with similar commercial ambitions — their goal of colonizing Mars aside — and they've already had success with reusable rocket technology. SpinLaunch, however, is taking a different approach.

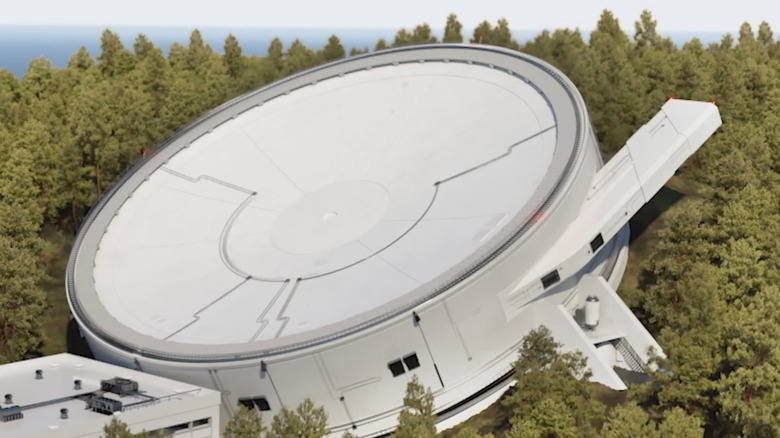

In the New Mexico desert stands a circular 1,000-ton steel vacuum chamber with what looks like a torpedo launch tube jutting upward from one side. It would look down on the Statue of Liberty if they were side by side. And this is just a suborbital proof-of-concept launch system. The planned orbital launch facility will be three times this size. Is this an early vision of what's to come?

Project HARP

For a glimpse into commercial space's potentially electric future, let's first make an unlikely pitstop in the past. Namely, 1960's Barbados. There's a loaded gun near the coast. It weighs 200 tons, making it the most massive gun in existence. The barrel has a 16-inch bore diameter and is nearly 120 feet long. It's aimed a few degrees shy of the vertical. It fires a 185-pound payload 112 miles into the sky. The Kármán line — a widely used definition for the boundary between the Earth and space – is only 62 miles high. The launch acceleration on the payload is 15,000 G. What in the world is going on here?

This was Project HARP, the aptly named High Altitude Research Project. It was a program led by McGill University's Gerald Bull and sponsored by the US Army's Ballistic Research Laboratory and the Canadian Armaments and Research Development Establishment. It was an exploration into easier, cheaper, and more reliable ways than conventional rockets to put payloads such as satellites into Earth orbit.

Everything here was essentially just as it seemed: It was literally a comically enormous gun firing projectiles using powered propellants. It did make use of two clever designs, though. First, the air was sucked out of the barrel prior to launch, reducing drag and increasing launch velocity. Second, the projectiles were fitted with small rockets that would fire only after they reached the upper atmosphere. Project HARP was shuttered after only a few years, but in many ways it did achieve its goals, and its lessons have not been forgotten by SpinLaunch.

Space yeet!

Like the gigantic space guns of Project HARP, SpinLaunch uses specialized equipment to accelerate their payloads to outrageous velocities while still at sea level. In SpinLaunch's case, this is achieved not with gunpowder but with an advanced centrifuge operating in a near vacuum. The yet-to-be-built L100 Orbital Mass Accelerator will build upon the lessons of the already operational A33 suborbital accelerator. A large carbon fiber tether will hold the payload and begin spinning, powered by an electric motor. When it reaches hypersonic speeds – as fast as 17,000 mph, according to CNN –the tether will release the payload into the launch tube.

In order to maintain the airless environment inside the spin chamber, a pair of doors will open and reseal in rapid succession to let the payload pass through the tube before the air rushes in. At this point, the payload will be suddenly subjected to immense air resistance. Its incredible velocity and mass will be sufficient to get it from sea level to the thinner upper atmosphere before friction overheats and destroys it.

What we've so far only referred to as a payload is actually a ballistic shell. When it reaches a high enough altitude, the shell will split open and fall back to Earth for recovery and reuse with minimal repair. The contents of the shell include small chemical rockets as well as a number of satellites. In the upper atmosphere, the miniature rockets are enough to propel the satellites into Earth orbit.

Top marks for the bottom line

Somewhat surprisingly, the unconventional and complex launch chamber — and all that goes into making it functional — is potentially a huge improvement on the price performance of putting a payload into orbit. The electric launch system saves tremendously on the need for rocket fuel, which is doubly helpful. The fuel itself is expensive and often requires extremely cold temperatures, making it difficult to work with. Moreover, the weight of the fuel in a traditional rocket needs to be lifted off the ground by burning even more fuel, which adds even more weight, and so on. SpinLaunch largely skirts this issue.

The electric-powered rotating tether can recover some of its energy after releasing its payload by using regenerative braking. By having many identical and reusable capsules, SpinLaunch envisions a capability of 5 to 10 launches per day with a price tag of just $250,000 per flight.

That might sound like a lot, but according to NASA, launching the space shuttle to Low Earth Orbit cost $54,500 per kilogram, and SpaceX's Falcon 9 costs $2,720/kg. At $250,000 per launch and a payload capacity of 200kg, that's just $1,250/kg, or less than half the current competitive rate. The only disadvantage? Due to the tremendous forces, this is not a system made for humans. SpinLaunch has incredible potential to help further commercialize space, but they won't be catering to space tourists anytime soon.