As F-150 Lightning Reservations Climb, Ford Tackles The Big EV Bottleneck

Ford has taken more than 44,500 reservations for its F-150 Lightning pickup, though while production isn't set to begin until 2022 the automaker is already taking steps to ensure battery supply keeps up with EV truck demand. The all-electric version of the F-150 opened up for reservations earlier this week, with would-be owners staking a place in line with a $100 refundable deposit.

Within the first 12 hours, Ford later confirmed, it had seen more than 20,000 reservations for the EV. Now, in under 48 hours, that total is past 44,500 reservations, Ford CEO Jim Farley confirmed.

Clearly, there's a big difference between reservations and actual confirmed orders, and it remains to be seen how many of those placeholders actually go on to buy the 2022 F-150 Lightning. Ford ran a similar reservation scheme for the Mustang Mach-E, its all-electric crossover, though has not said how many conversions it saw there either. That's similar practice to the rest of the auto industry, mind, with companies like Tesla and others typically not discussing just how many reservation-holders actually commit in the end.

One outlier there is the new Ford Bronco. The equally-eagerly-anticipated truck – that Ford will bring back to dealerships later this year – opened for reservations with a similar system last year, after it was first announced. According to Ford's Mike Levine, Product Communications Manager for the North American region, Bronco order conversions have been at around 66-percent from the 190,000+ reservations ahead of the actual order books opening.

Part of the F-150 Lightning's appeal is its unexpectedly low starting price, with the commercial version of the electric truck starting at around $40,000 before subsidies and EV incentives. Part of the reason Ford could achieve that, execs at the automaker have said, is standardization of many key parts with its other electric vehicles. By taking a so-called catalog approach, rather than designing custom components for each model, it can rely on economies of scale to keep overall cost down.

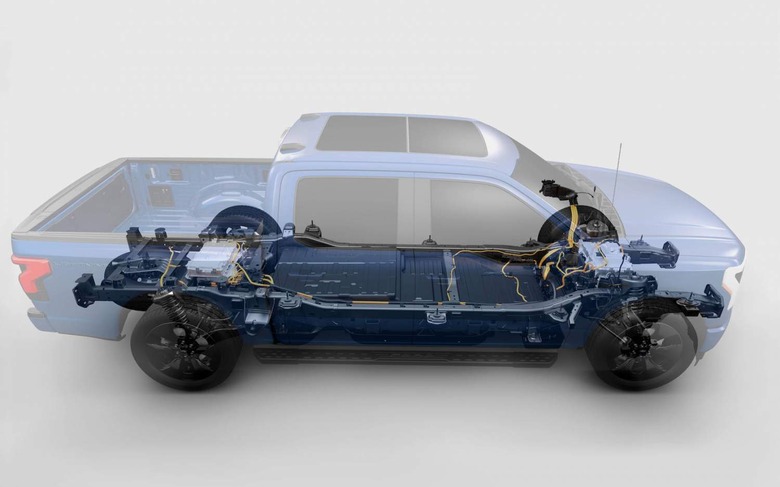

Still, there's no getting past the sheer number of items like battery cells that will be required, particularly given Ford's ambitions to eventually offer electrified versions of all its vehicles. While battery packs are typically the single most expensive component in an EV, they can also be the biggest bottleneck.

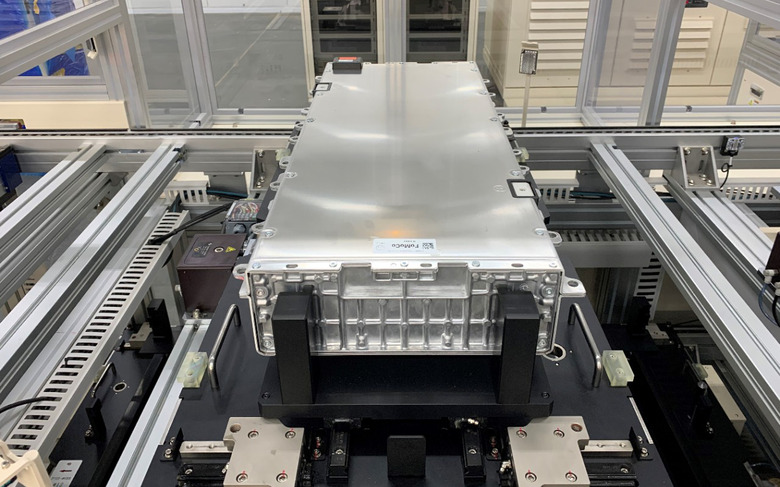

To help avoid that, Ford has inked a deal with SK Innovation on battery production. BlueOvalSK will, according to the two companies' memorandum of understanding, a joint-venture to build battery cells and arrays in the US for future Ford and Lincoln vehicles. From mid-decade, Ford says, it expects BlueOvalSK to be producing approximately 60 gigawatt hours (GWh) in traction battery cells and array modules annually.

That still leaves room to expand production further, Ford adds, and it's probably a good thing. The automaker predicts it'll require up to 240 GWh annually for its vehicles worldwide, with North America alone accounting for 140 GWh of that.

SK Innovation has already been tapped to provide the batteries for the F-150 Lightning, though it'll be next-gen cells and arrays that BlueOvalSK focuses on. Ford has been working on developing those technologies, and last month announced it would be opening a new, dedicated R&D facility – Ford Ion Park – to develop and test the new batteries. The automaker also joined with BMW in investing in solid-state battery developer Solid Power this month, with a mind to use that company's technology to build next-gen batteries on existing li-ion production lines.

That appetite for batteries is in part because Ford isn't just seeing them as a tool for propulsion. The F-150 Lightning, for example, can also double as a whole-home emergency backup battery and, in time, will act as a power reserve to help manage solar and peak grid demand.