Revolutionary Method Allows 3D Printing With Metal Harder Than Steel

3D printing has become one of the most efficient and affordable ways of creating simple, specific items without having to purchase them. But while 3D printing can save you money on some things, it's perhaps more of a niche and not widely embraced by the public overall. However, that could all change thanks to tungsten carbide–cobalt (WC–Co) cemented carbide, developed by engineers at Hiroshima University in Japan.

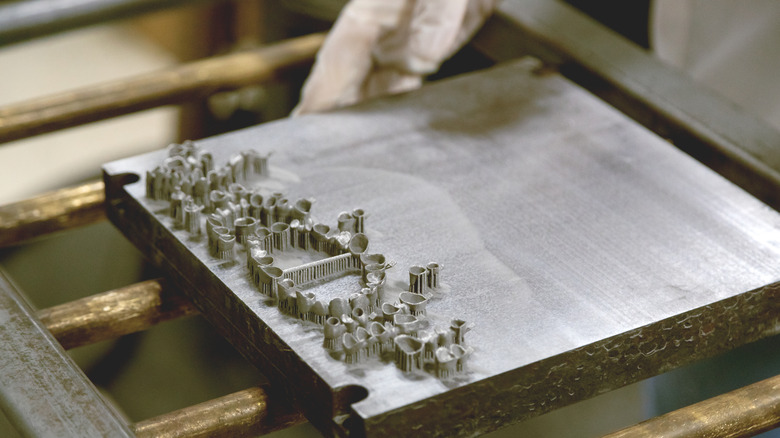

The cemented carbide is the direct result of a new study conducted at the university, which incorporates additive manufacturing, also known as 3D printing. The process produces the new metal more efficiently than it was previously made, creating less waste while saving money at the same time. But the most impressive thing about the 3D-printed WC–Co is the metal's hardness, which is above 1,400 on the Vickers hardness (HV) scale. This means that it's much harder than many common steels, including martensitic stainless steel, which maxes out at 800 HV and tool steel, which can reach 1,000 HV.

The 1,400 HV was achieved by softening the elements that comprise the 3D-printed metal instead of melting them down completely. This allows the new metal to keep a superior hardness, as well as structural integrity, which is important for future applications. Those applications can include repairing cracks and even improving the toughness of existing construction. Hiroshima University's study is expected to be published in the April 2026 issue of the International Journal of Refractory Metals and Hard Materials.

Real world use cases of 3D metal printing

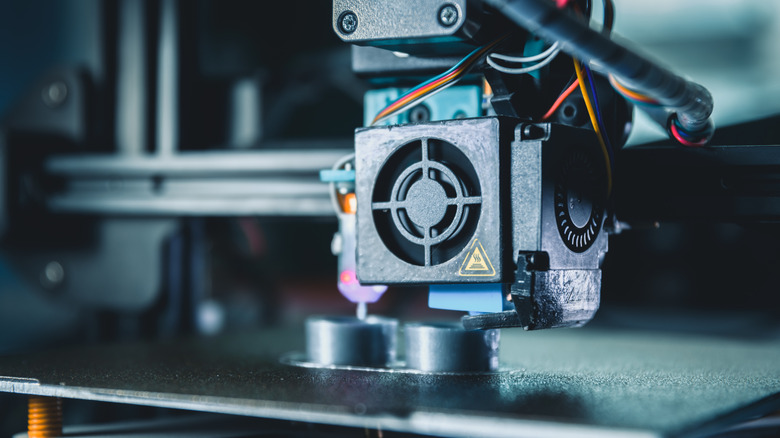

Traditional 3D metal printing, also known as Metal Additive Manufacturing (MAM), fuses a laser or electron beam with metal powder. That substance is then used to construct an item one layer at a time, using a 3D digital model as a guide. This allows the user to create complex shapes that can be customized while utilizing only the metal that's needed for the project. 3D printing can be done with a variety of metals, including steel, cobalt-chrome, aluminum and titanium.

MAM is being used across several industries, including aviation and aerospace. That's because engine components, like those in General Electric's GE9X, one of the world's biggest engines, need to be lightweight. It can even be utilized for more complex structures like satellites and spacecraft, where 3D-printed parts can be used to repair existing parts or create new ones. The US military is also using 3D printing technology for aircraft parts, with larger and more complex equipment being produced for other purposes as well.

But MAM is impacting people in everyday situations, as it can be used to create lightweight passenger vehicle parts. The 3D printing process helps automotive designers work more efficiently and at a quicker pace than ever before. 3D printing can also be used for a variety of medical applications, including the creation of orthopedic implants. Dental implants like crowns and bridges can be printed as well, with each piece fully customizable based on the patient's specific needs.