Which Torque Wrench Type Is The Most Accurate? It's Complicated

From my experience teaching mechanics to properly torque fasteners in the aerospace industry, the potential accuracy of any torque wrench type is often defeated by user error. However, some torque wrench types allow users to achieve more accurate results thanks to their design features. A comparison between Snap-On and Harbor Freight Icon torque wrenches posted by Project Farm shows that Snap-On torque is slightly more accurate than the less expensive option out of the box, but neither wrench had an error exceeding 2% across 25 attempts.

Still, most users find Harbor Freight torque wrenches are accurate enough for their needs. The trick is to determine which torque wrench is most accurate for a given task, and that's where it gets complicated.

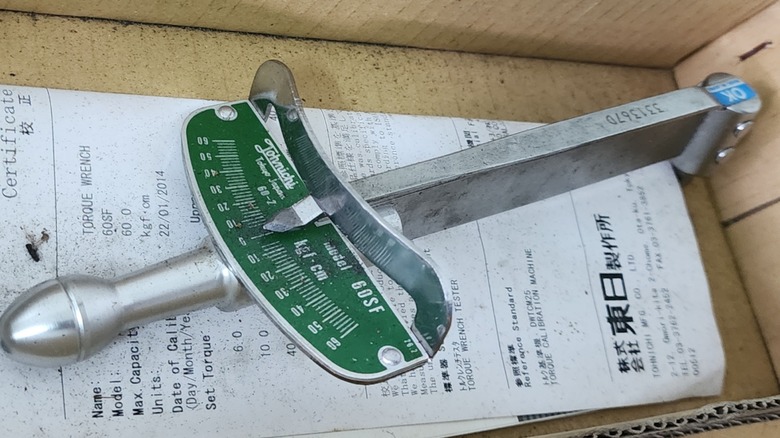

There are four primary types of torque wrenches: deflecting beam, dial indicator, micrometer click, and electronic digital. The Jason Explains Things YouTube channel conducted an accuracy test pitting a decades-old deflecting-beam torque wrench, the host inherited from his grandfather, against more modern micrometer-click torque wrenches from Tekton and Icon. The test results found the old-school wrench significantly more accurate than the others, with a maximum deviation of 2% at 100 foot-pounds and higher accuracy at lower torque values.

Project Farm's test revealed several digital torque wrench brands with deviations below 1% when new and after 1,000 cycles. For comparison, Precision Instruments advertises a ½-inch Drive Dial Type Wrench with accuracy to 1%. While all torque wrench types can deliver accurate torque application, the digital torque wrench is often the most accurate for most users under a variety of conditions.

Besides accuracy, what makes one torque wrench type better?

The deflecting beam torque wrench is the simplest type. It uses a solid beam connecting the handle to the square drive, along with a pointer that indicates the applied torque on a scale. It doesn't require any pre-torque setup or use any batteries. Dial torque wrenches operate using a similar mechanism, except the pointer activates the dial indicator. Micrometer-click torque wrenches use springs and gears, while digital types use complex electronics.

Ultimately, every type of torque wrench is a delicate precision instrument capable of serviceable accuracy. That also means they require recalibration if dropped and should never be used as a breaker bar or in any situation that exceeds their rated capacity. While they're all accurate enough, some types have features that make them better than others.

Some torque application tasks take place with easy access to the fastener. Other times, the process takes place where the torque wrench is difficult to see, ruling out the use of deflecting beam and dial-type torque wrenches. These situations are best suited for click-and-digital types.

Click-type torque wrenches can be difficult to set, making them less than ideal for multiple fasteners that require different torque values. Digital torque wrenches are easier to set and provide continuous feedback to prevent over-torquing once the set value is reached. Click torque wrenches only click once upon reaching the set torque value, with no further indication to stop if it's not felt or heard.