Who Makes BMW Engines And Where Are They Manufactured?

Alongside Honda and Suzuki, BMW is one of the rare companies that have managed to earn a coveted position in the minds of folks interested in both cars and motorcycles. The BMW Group operates 32 manufacturing plants worldwide, 26 of which focus on cars and the remaining six on BMW's motorcycles. Narrow that list to facilities that manufacture or assemble engines for BMW cars, and it becomes much shorter. As of 2026, five facilities manufacture internal combustion engines bound for BMW cars. Of those, two plants are located in Europe, with one being the Steyr plant located in Austria, and the other being the Hams Hall plant in the U.K.

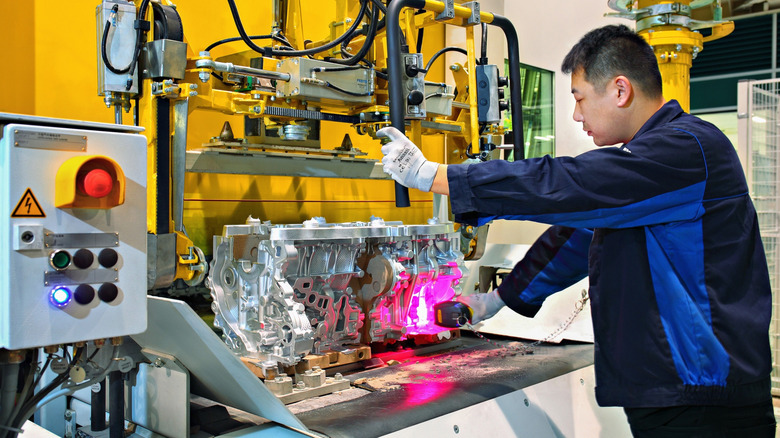

The other three plants are located in Asia, which include the Shenyang plant in China, the Kulim plant located in Malaysia, and the Force Motors plant in India. Note that the engine assembly facilities in Malaysia and India are third-party contract manufacturers set up in partnership with local companies: Sime Darby Auto Engineering in Malaysia and Force Motors in India.

BMW's plant in Munich also used to manufacture engines, but it is currently being repurposed as an EV-focused plant focusing on vehicles like the BMW iX3, which is based on the Neue Klasse X concept. Given that BMW assembles cars in dozens of locations around the world, every internal-combustion BMW relies on engines produced at one of these specialized facilities. Once manufactured, these engines are shipped to the final assembly locations around the world.

History of BMW's engine manufacturing plants

BMW's foray into automobile engines began in 1919, when it manufactured the flat-twin M2B15 engine for Victoria Motorcycles. In 1923, the company launched the R 32 motorcycle, the first BMW motorcycle to use a BMW engine. BMW jumped over to manufacturing cars by 1928, after it started making a rebadged version of the British car Austin Seven. In 1932, BMW launched an updated version of the same car with a redesigned, improved engine. The BMW 3/20 PA AM1 debuted that year and is widely considered the first BMW car with a BMW-built engine. They were both assembled at BMW's Eisenach plant. Post World War II, BMW lost control of the Eisenach plant, and was forced to stop producing cars until the early 1950s.

The modern era of BMW's car and engine manufacturing restarted in 1952 when the company launched the BMW 501. It also marked the beginning of car and engine manufacturing at the Munich plant. In 1979, BMW opened a new plant in the Austrian town of Steyr, dedicated to engine production. It remains the company's largest engine plant. BMW's second engine facility, this time in the U.K., commenced operations in 2001, and is where engines for BMW's MINI-branded cars are assembled.

The only BMW-owned and operated engine assembly facility in Asia is the Shenyang plant, which opened its doors in 2004 and has since witnessed several expansions. It's now the largest BMW manufacturing facility in the world. In fact, one in three BMW cars sold today traces its origin to the Shenyang plant.

BMW's contract engine manufacturing plants

BMW's entry into cost-sensitive markets in Asia led the company to change its approach to operating from wholly owned manufacturing facilities. An example of such an arrangement was seen in India, where BMW made its official debut in 2006. From 2006 to 2015, BMW's manufacturing facility in Chennai, India, assembled only Completely Knocked Down (CKD) kits into cars. Following changes to India's customs duty rules, BMW forged an alliance with an Indian company called Force Motors. This led BMW to open its first engine manufacturing facility operated by a 3rd-party manufacturer in 2015. As of 2026, the Force Motors facility continues to manufacture engines for BMW cars sold in India. It is pertinent to note that BMW Motorrad has followed a similar strategy with its low-cost motorcycles, in which some engines for entry-level models are manufactured in India by the motorcycle company TVS.

Another country where BMW used a similar strategy is Malaysia, where BMW forged alliances with several local companies. It began formal operations in Malaysia in 2003, and since 2007, BMW has been in a partnership with Sime Darby Auto Engineering (SDAE), resulting in a manufacturing plant where BMW cars intended for the Malaysian and broader Southeast Asian markets are assembled. In 2018, this partnership was further solidified when the same plant started assembling engines.

Today, this facility continues to supply engines for BMW cars sold locally. The two engine manufacturing facilities in Malaysia and India are the only car-engine focused plants that are not under the direct operational control of BMW. This is also the reason these facilities are not listed on BMW's website detailing all its production facilities.