How To Cut A Straight Line With A Circular Saw If You Don't Have A Guide

A good circular saw from a major brand is often one of the first power saws to be added to a woodworker's collection. Not only are they affordable, but these lightweight and incredibly portable tools can make just about all of the same kinds of cuts that a table saw and a miter saw can. They're also incredibly useful when it comes to breaking down large sheet goods, such as MDF and plywood.

The main issue with circular saws is that they aren't very accurate all on their own. Table saws and miter saws have the luxury of fences, jigs, and other devices that can be used to make incredibly accurate cuts without the need for much skill on the user's part. Cuts on circular saws, on the other hand, are easy to mess up. These tools require preparation, skill, and attention to detail to achieve a straight and accurate line. One of the easiest ways to achieve straight lines is to use a guide. There are specialty guides that can be attached to pieces which you can buy at the hardware store, you can make a DIY jig that lines both the base and the blade with the edges of a couple of attached pieces of wood, or you can simply clamp a 2x4 to the piece you're working on.

That said, these methods can be time-consuming when you have to make a lot of cuts, and you don't always have a guide at the ready when working on a project. Freehanding might not be quite as precise as using a guide, but there are a few techniques that you can employ to get fairly straight cuts. Just be sure to follow all of the recommended safety precautions, as you would with any other cut.

Preparation is key

Even if you aren't taking the time to use a guide, you still want to make sure you're setting yourself up for success with each of your cuts. You'll want to measure and mark each of your cuts with a fine line. This can be achieved with a good, sharp pencil or with a scoring knife. Keeping the edge of the saw in contact with a thinner line will help to ensure a straighter and more precise cut.

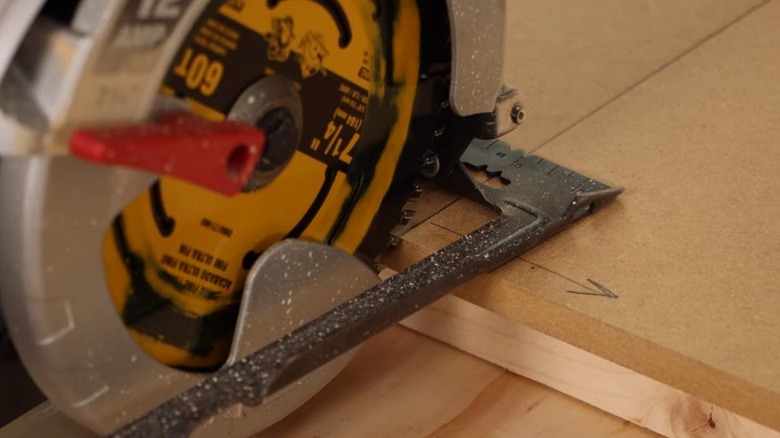

Once you have your line marked, you'll need to line up the saw. The kerf of the circular saw blade is going to remove some of the material as it cuts, so you're going to want to line up the edge of the saw blade on the outside edge (waste side) of the line. Pressing the blade straight into the line will result in the end piece being a fraction of an inch shorter than your measurements.

You're going to want to make sure that your circular saw is perfectly in line with the cut before the blade touches the wood. Circular saws are designed to cut straight, so any deviation at the beginning can throw off the trajectory for the rest of the cut. Some saws have laser sights built into them. These can help you line up the cut correctly and stay in line for the duration of the cut. You'll also want to be mindful of the blade guard. The Honest Carpenter recommends allowing the guard to raise against the wood as you cut when the angle is square. However, lifting it prior to the cut when it's angled, as leaving it down, can put extra tension on one side of the saw and make the tool difficult to keep straight.

Keep your eye on the blade

As you start the cut, you're going to want to keep the blade ⅛-½-inch from the project before you pull the trigger and let the blade get fully up to speed before pressing it forward. Use both hands to keep the saw as stable and controlled as possible, making sure that your body is always in a position that gives you adequate leverage and control. Setting up larger sheet goods just off the ground with a sheet of rigid foam is a good way to ensure that you don't have to lean in a way that will throw off your cut.

As the blade makes contact with the board, you might be tempted to keep your eyes on the laser sight, or on the markings at the front of the baseplate, but these may not be 100% accurate. The better option is to keep your eye on the front of the blade itself. Keep the edge of the kerf right up against the outer edge of your cut line, moving slowly and making sure that the blade is straight. This is most challenging at the beginning of the cut because most of the blade is hovering off the edge of the board, and it could easily come in at an angle.

Back the saw off immediately if this happens and try again. One trick recommended by Out of the Woodwork is to use a utility knife to make an initial kerf notch in the wood exactly where you want the circular saw blade to land. This helps guide the saw into the cut at a straighter angle. Once the saw blade has fully made its way into the piece, it will become much easier to keep straight.