How The Color Of Your Diesel Engine Can Help Tell You Who Made It

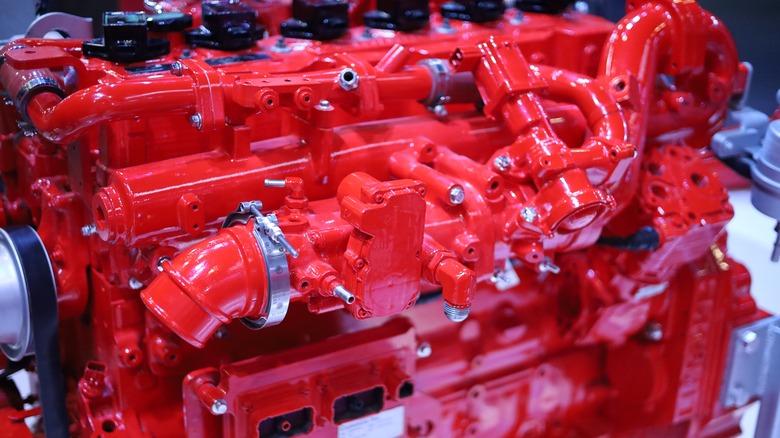

Knowing what company manufactures specific parts of your car can be tough, especially if you don't have easy access to the information. When it comes to semi-trucks and other heavy-duty vehicles, however, one dead giveaway can be the actual engine color. For example, the diesel engines built by Cummins are typically painted either black or blue. This has been the norm for the company for several years, making it an easy way to know if you have a true Cummins under the hood. However, some Cummins engines are painted red as well, specifically the ISX series.

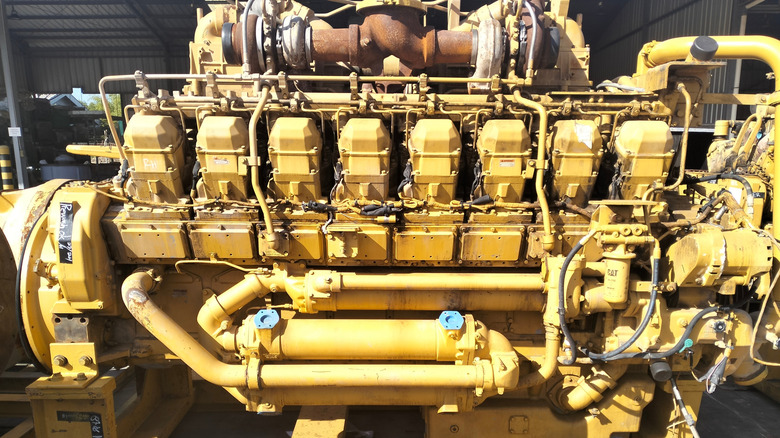

Other manufacturers have used different colors as well, including Caterpillar, with their trademark yellow engines. In this case, not only does yellow immediately identify who made the engine, it's also the same color Caterpillar uses on their equipment. Paccar engines are painted white, which helps if you have a leak, while Mack exclusively sticks to the color black for their engines.

Before you see the color of a diesel engine and think you know what you have, beware that manufacturers have been known to change their color schemes through the years. For example, when GMC updated their Toro-Flow diesel engine to the Toro-Flow II in 1969, they switched from gold to green. Though the color was secondary to the actual performance of the engine, the color swap did signal that the company had made a change, and that its customers could expect something different moving forward.

Solving for engine protection and sustainability

The use of paint on diesel engines wasn't necessarily just to identify the manufacturer, but to help protect the engine as well. At one time, these heavy-duty engines were made from grey iron, a metal that could easily rust. In order prevent corrosion and extend the engine's life in the process, paint was used as a barrier. This provided an important layer between the internal parts of the engine, and the exterior elements.

Paint was also important to safeguard engines, including the best ever made by American companies, from extremely high temperatures. Without it, the engine's components would break down, and in some cases, even warp. Heat-resistant pants were the solution, and could withstand temps of more than 1,400 degrees Fahrenheit. Today's technology has helped address this issue, with some coatings utilizing silicone to build stronger bonds with the engine's surface. Not only is the coating harder, it's also far more durable than previous paints.

Beyond these protective measures, painting diesel engines can actually have an important environmental impact, which wasn't possible in years past. Today's paints are more eco-friendly, and are only used where needed, thus optimizing the process. This cuts down the on the fumes, and chemical waste. One company that's integrating this new process is Cummins, which is also working with water-based paints for more reliable, cleaner results.