What Does PLA Stand For In 3D Printing?

Readers find themselves at a time of unprecedented technological advancement. And while many of these world-changing developments dominate news headlines, one that flies under the radar is the rise of 3D printing, an industry that is projected to grow by nearly 25% year-over-year throughout the decade and has the potential to change a variety of industries, from space exploration and ecologically friendly housing development to orthopedic surgery. As such, knowing the basics of how 3D printers work, what materials are used, and their potential applications could be essential to understanding the future landscape of your profession and hobbies.

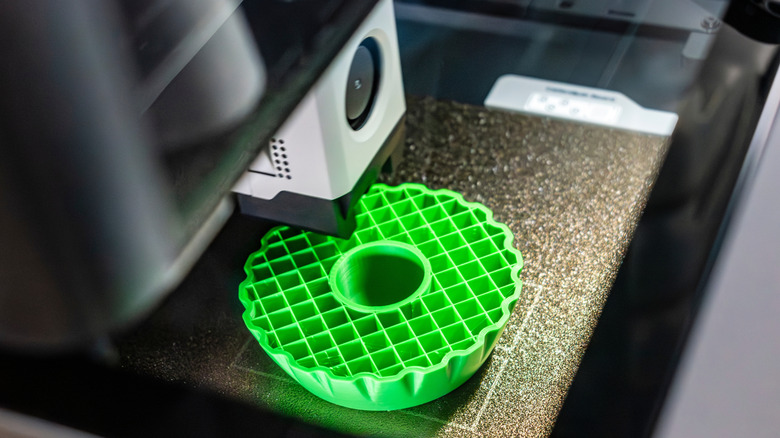

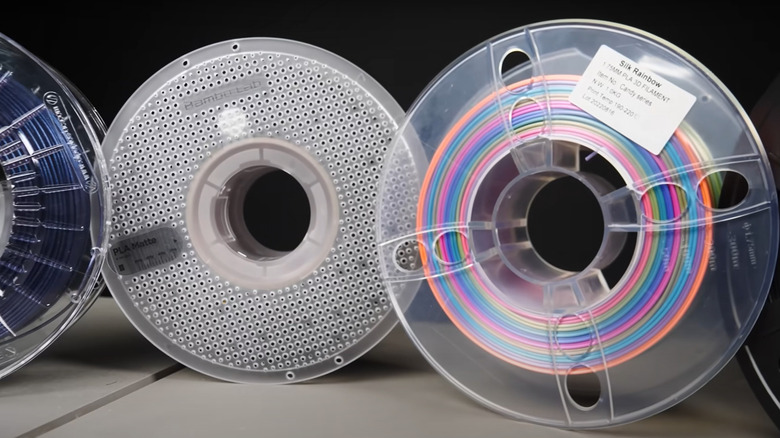

The most common 3D printing types follow a Fused Deposition Modeling design, in which layers of melted filament are deposited atop a base platform following a pre-loaded digital design structure. Reading the list of FDM materials can feel like moving through a medical textbook, with lists of abbreviations like ABS, PETG, and PEI. The most popular filament for 3D printers, however, is polylactic acid (PLA), or polylactide. PLA is a thermoplastic typically made of sugarcane or cornstarch. The polymer is popular with at-home and industrial 3D printers alike, as it is cheap, environmentally friendly, and requires a relatively low melting point. It is also fairly easy to print, making it an ideal filament for 3D printers geared towards kids and teens.

PLA at a glance

Since its invention in 1930, polylactic acid has been one of the most popular plastics in the additive manufacturing industry. Now gaining a second life with FDM 3D printers as one of several durable consumer-grade 3-D filaments, PLA continues to gain traction due to its ease of production and use. To make polylactic acid, scientists ferment starchy plants like sugarcane, maize, and cassava, breaking down the materials into lactic acid before using one of two polymerization methods: ring-opening and condensation.

Some polylactic filaments, known as PLA+, are customized by incorporating other ingredients to change the appearance, stability, malleability, and ultimate tensile strength of the filament. For instance, infusing carbon fiber increases the strength and stiffness of prints but makes the printing process harder on your nozzle. On the other hand, metal powders like brass, copper, and bronze provide metallic finishes with improved mechanical properties. Biomass additives, like bamboo, wood, hemp, or flax, can increase strength and tensile flexibility while giving creations a more realistic appearance. One major drawback, however, is price, as PLA+ filaments are typically more expensive than their PLA counterparts.

Due to its natural ingredients, PLA is more environmentally friendly than most filaments, although its biodegradability is heavily debated. Despite being derived from degradable starches, the manufacturing process causes it to be highly resistant to degradation, meaning it only breaks down quickly under specific aerobic conditions. As such, PLA degrades quickly in industrial composting processes but can take up to 80 years to decompose in nature. With that said, the filament is still a more environmentally sustainable solution than many of its competitors, as its manufacturing process takes 65% less energy and emits 68% less greenhouse gases than traditional plastics.

Is PLA right for you?

Printing using PLAs is straightforward, making it a popular choice for at-home hobbyists. With a low service temperature, relatively inexpensive printers with low nozzle temperatures can apply the polymer without problems. It also means that you don't need to use a printer with an enclosed printing space. Compared to alternatives like Acrylonitrile Butadiene Styrene (ABS), PLA is less sensitive to temperature changes during layering, making it very dimensionally accurate and less likely to warp. With PLA filaments, sharp corners and finite details are easier to print. High levels of intra-layer bonding give PLA-printed models smoother surfaces while making it a more forgiving material when beginners mess around with their printer settings.

While PLA is ideal for cosmetic models, its lack of toughness and low impact resistance make it structurally unsuitable for objects likely to undergo high stress. As such, engineers tend to avoid the material when building bearings, parts, or test pieces. Likewise, its low melting point — a major selling point for beginners — makes it susceptible to melting or morphing under heat, often deforming if left in direct sunlight. Exposure to water and chemicals can also warp polylactic acid, further hurting its outdoor applications.

With these strengths and weaknesses in mind, amateurs and professionals alike typically opt for PLA filaments when making models and prototypes, decorative figurines, containers, toys, and gadgets. PLA+ creations bring more strength, flexibility, and heat resistance than their PLA counterparts, and thus can be a good option when such properties are required.