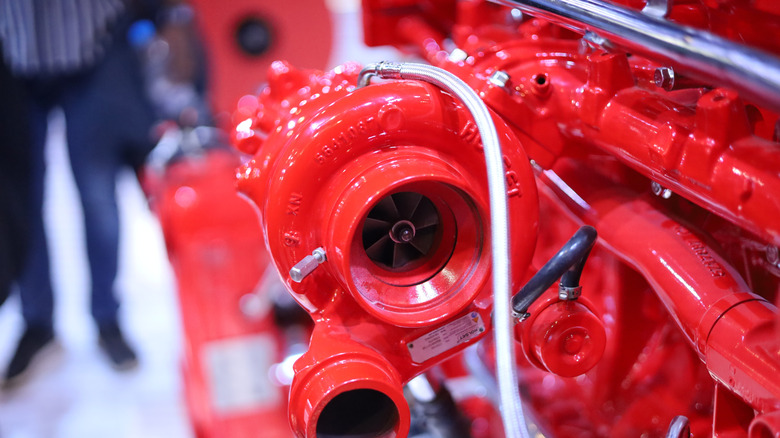

How Does A Variable Geometry Turbo Work & Do All Cummins Engines Have Them?

Turbochargers are one of the best methods for extracting more power out of an engine with less total displacement. Unlike a supercharger, which compresses air at the intake stage and runs off a belt tied to the engine itself, a turbocharger utilizes exhaust gases to spool up and compress air via a system of turbines before feeding that air into the engine's intake. Effectively, it's a supercharger which runs on an engine's waste byproducts, which is why it's so useful in generating power.

Various companies produce turbos, each with its own proprietary design nuances that make them uniquely suited to the cars they were designed to equip. One of the most innovative of these designs, however, is the variable geometry turbo, or VGT, which improves upon the standard fixed-blade turbocharger. Most often seen on diesels, the VGT uses a specialized set of vanes on the exhaust side of the turbo housing. This changes the geometry of the exhaust flow through moving or pivoting, depending on the system. This speeds up or slows down the gases, therefore keeping the airflow at an optimal rate for a given RPM. This is particularly useful in diesel applications because diesels are low-revving and use the lower RPM bands more than typical cars. Changing the geometry of the airflow, therefore, helps boost low-end power delivery and compensate for turbo lag.

Cummins subsidiary Holset pioneered this technology in the late 1990s, equipping its lineup with VGTs in addition to traditional fixed-blade turbos ever since. Cummins doesn't use VGT in all its engines. Nor is it the only company to use VGTs. Major brands like Ford and General Motors also utilize the technology in their own respective diesels, with other manufacturers like Garrett using their own systems.

How VGTs work

Before we dive into the pros and cons, let's first discuss how the technology actually functions. Turbochargers are complex components featuring a number of different moving parts; all a variable-geometry turbo does, in principle, is alter one or more of these parts' shapes by pivoting, closing, or opening to affect the airflow in some way. This means that there are several methods for accomplishing the same task, from changing turbine blade geometry to utilizing moving walls inside the turbo housing. The method first patented by Holset in 1998 used axially-sliding vanes to manipulate the airflow.

Airflow is the entire purpose of a turbocharger, but an engine requires different amounts of airflow at different times. At low speeds, a turbocharger may struggle to produce the required power simply because there's not enough exhaust flow going through the system yet, leading to turbo lag. On the opposite end, if the turbo spins too quickly, you risk overspeeding the system and creating an overboost situation; wastegates typically mitigate this problem. Effectively, this means that, depending on the engine's RPM, it requires a specific amount of airflow to operate correctly, and that's where the VGT comes into play.

In this style of VGT, the vanes close at low engine speeds, restricting airflow and cutting down lag times while increasing boost pressure — less space means more pressure. Conversely, at high speeds, the vanes open to maintain optimal pressure while preventing overspeed and maximizing exhaust gas flow, combining the best of both worlds.

How the ones Cummins uses function

Cummins isn't the only company to use variable geometry technologies, with several viable methods employed by a number of companies. As for Cummins, and by extension Holset, its system is tailored to the commercial sector through its simplicity. These aren't turbos built for maximum performance, but rather maximum reliability, so Holset's system utilizes as few moving parts as possible with minimal wear sites to optimize the VGT for longevity and durability.

Holset accomplishes this through a patented sliding nozzle ring. This is a single ring with the vanes fixed onto it. The ring moves up and down inside the turbo housing, acting as a physical block that forces the air to move through the vanes when closed, or leaving airflow unobstructed when opened. It's basically the same principle as putting your finger in front of a garden hose to change the direction and pressure of the water.

This system is found on many Holset turbos found across the Cummins lineup, ranging from light to heavy-duty applications. For instance, the 6.7L turbo diesel on a RAM truck utilizes this turbo assembly, among other Cummins-powered vehicles. Because it's designed principally for commercial work, the system emphasizes lowered running costs, higher efficiency, and versatility. However, it's only the tip of the iceberg as far as variable geometry turbos in general go; with so many systems accomplishing the same task, there's likely one for every build out there.