How The Detroit Diesel Series 60 Engine Played A Pivotal Role In American Trucking

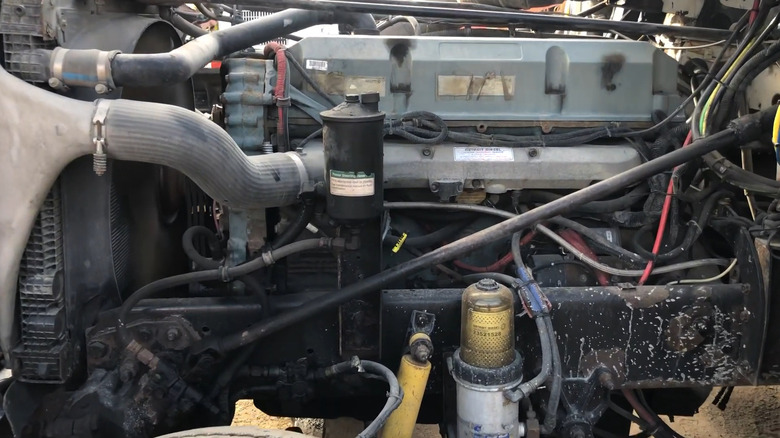

Detroit is one of the most impactful diesel engine companies in history, and the Series 60 is its most important engine to date. The Series 60 engine was developed in 1987 with the purpose of creating a heavy-duty yet fuel-efficient engine for trucks in North America. It became the most used heavy-duty diesel engine in the U.S. by 1992, used in not just heavy-duty trucks but also boats, emergency vehicles, and mining equipment. The success of the Detroit Series 60 is due to its advanced technology and fuel efficiency.

The Series 60 is the first fully electronically controlled heavy-duty diesel engine ever made. Most modern engines now rely on electronic control modules (ECM) inspired by the Detroit Diesel Engine Control (DDEC) to optimize their performance and efficiency. These modules are located within the engine, collecting data from various sensors on the engine and throughout the vehicle. Based on the collected data, the electronic controls will make adjustments or diagnose any issues with the engine, making the engine more reliable for longer. While other Detroit engines may be more powerful, the Series 60's innovations paved the way for modern truck engines.

How the Series 60 DDEC works

The Detroit Series 60's DDEC essentially acts as the engine's brain, cutting maintenance costs and increasing efficiency by managing all of the engine's tasks and making adjustments based on incoming data. This includes the Series 60 engine's turbocharger boost, fuel pressure, emissions, coolant temperature, and more. There are a handful of essential parts in electronic control modules that keep everything running smoothly.

First, there's the microcontroller that manages all of the ECM's other components. It gathers and processes all of the data from sensors throughout the engine to take the best possible actions for efficiency and reduced emissions. The memory stores the ECM's operating system, firmware, and data to both adjust things as needed in real time and also provide information to technicians if maintenance is needed later on. The input and output ports connect to vehicle sensors to move data, the analog-to-digital converter converts analog signals from those sensors to digital signals the ECM can understand, and the voltage regulator ensures the ECM has a steady supply of voltage from the vehicle's battery to reduce emissions and run everything smoothly.

The history of Detroit engines and the Series 60

Detroit started out as the GM Diesel Division under General Motors back in 1938 and has since become one of the biggest diesel engine companies in the world, often compared to Cummins. The initial focus of the GM Diesel Division was on creating engines for construction and military vehicles, which became vital during World War II. The company pivoted to heavy-duty engines in 1955, meant for commercial trucking. The industry was growing rapidly in the 1950s thanks to the implementation of the interstate highway system, meaning more heavy-duty diesel engines were needed than ever before.

In 1988, a year after the Series 60 was revealed, General Motors and Penske Corporation joined forces to create the Detroit Diesel Corporation (DDC). The DDC's on-highway market share skyrocketed from 3% to 33% by 1993. The millionth Series 60 engine was sold in 2008, showing the relevance and continued performance of the heavy-duty engine decades after its launch. To this day, the Series 60 is Detroit's most successful engine. It was discontinued in 2011, but remains the most common engine found in Class 8 trucks. The diesel engines that have followed the Series 60, including the DD15, have pushed emission reduction and fuel systems even further.