Remanufactured Vs Rebuilt Engines: What's The Difference, And Is One 'Better?'

Arguably the single most important component in any car is its engine. The engine is what makes something an "automobile," after all — that is, able to move itself. However, engines are also usually incredibly complex pieces of machinery that must cope with unimaginable stresses. The inside of an internal combustion engine is one of the most violent places ever created by humankind, with pressures, temperatures, fast-moving gases, and more playing roles in a greater symphony that allows a car to go from Point A to Point B. What, then, occurs when something goes wrong? Not just the simple issues that involve basic care which you can do at home, but something truly catastrophic?

In that case, you generally have one of two choices, both of which require major automotive surgery. You can try replacing the engine with either something new or remanufactured, or rebuilding your car's current engine. Although these options sound similar and accomplish the same goal, they involve vastly different processes to get there.

In brief, rebuilding the existing engine involves tearing down the broken powerplant and reassembling it piece by piece, replacing anything that's broken along the way. This contrasts with a remanufactured engine, or "reman" for short, which involves detail-stripping the engine to its base components and comprehensively restoring it as close to factory-spec as possible, including creating and assembling components where needed to get everything perfect. Both have their upsides and downsides, of course, so let's discuss each in detail.

Engine rebuilds: the budget-friendly option

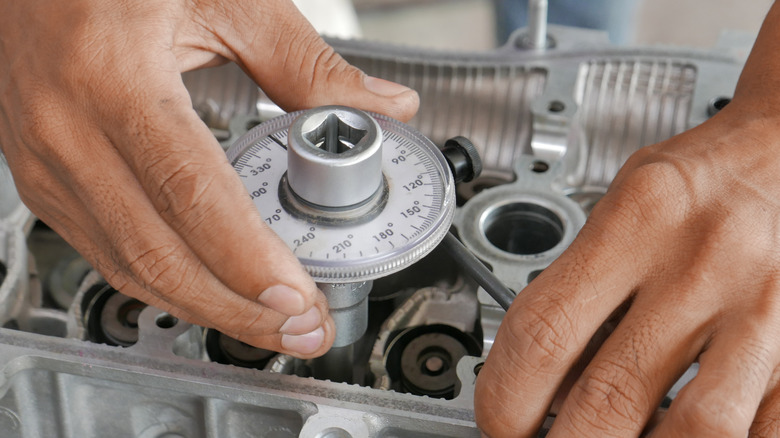

Often confused with engine overhauling, rebuilding a powerplant typically involves a mechanic detail-stripping the whole powerplant, replacing whatever appears worn or damaged. This service typically commands a sum in the mid-four-digit range, depending on various factors such as the size and complexity of the engine (more complex engines require more man-hours to dismantle), as well as the cause of the problem itself. That said, while it's still a large sum of money, this represents the lesser of two evils, being that it reuses most of the original components of the car. As such, rebuilding an engine is a procedure best performed with a certain wariness and trust. After all, any rebuilt component's longevity is ultimately frequently determined by the quality of workmanship, coupled with the way the car is treated. Generally speaking, however, mechanics will rebuild an engine and certify it with a brief warranty period of around a year / 12,000 miles, though this varies depending on the car and shop.

Being that all you're doing is replacing the worn parts, naturally, the downside of a rebuilt engine is that it leaves everything else alone. Similarly, some builders will opt to use used or salvaged components, meaning you're replacing one part with another that likely already has mileage on it. This is broadly why rebuilds demand more leeway with warranties; they're a riskier proposition, but a cheaper one as well. However, it's useful when you need to replace something specific that requires a teardown. For instance, if you need piston rings or there's scoring on a cylinder sleeve, then rebuilding the engine is a perfectly acceptable option.

Remanufacturing: serious work for serious purposes

Unlike rebuilding an engine, remanufacturing involves breaking an engine down piece by piece, and instead of rebuilding it as-is, you go all-out and replace everything not tied down with new parts. Effectively, you're building an engine from scratch here, machining components to match factory tolerances as closely as possible before refitting everything back together. The end result is the closest one can get to a truly zero-mile powerplant out of an original block.

The most obvious pro here is that you'll never have to worry about worn or used parts from a scrapyard. Remanufacturing something is a highly specialized job, with small, dedicated factories utilizing specific knowledge to remanufacture various components such as engines, transmissions, and accessories. One such company, for example, is Jasper, which remanufactures engines and transmissions for a variety of makes and models. The machining process is nothing short of comprehensive, utilizing new materials wherever possible and hand-fitting everything to original tolerances. Usually, the only component reused in this process is the block itself, albeit with metal inserts added to restore it to factory tolerances where needed.

Naturally, all this sounds expensive, and it is. That said, it's still often less than a brand-new crate engine, sometimes half as expensive, and usually boasts the original powertrain warranty — as it should, considering it restores the engine to OEM specifications. However, it's still roughly twice as expensive as rebuilding an engine can be, making it worth the money for many. Moreover, it may be your only option for restoring classics that require "numbers-matching" components, since not every classic car boasts the parts inventory required to rebuild an engine with used parts.