This Startup Company Is Spending Millions To Pick Mushrooms With Robots

In a world where robots can drive cars (albeit with obstacles) and write code, it was only a matter of time before one started picking mushrooms, and that's exactly what's happening at 4AG Robotics. The company recently raised $29 million in funding to scale its robotic mushroom-picking tech. While this all may sound quite strange, it's actually a smart solution to labor problems in mushroom cultivation.

Mushrooms bruise easily, grow quickly, and need to be harvested at just the right time. Mushrooms are usually picked by labourers who are trained in knowing which caps are ready and exactly how to carefully pick them. But that workforce is costly and hard to come by. 4AG stated on its website, "While other crops mechanized decades ago, mushrooms remained dependent on human pickers — until now."

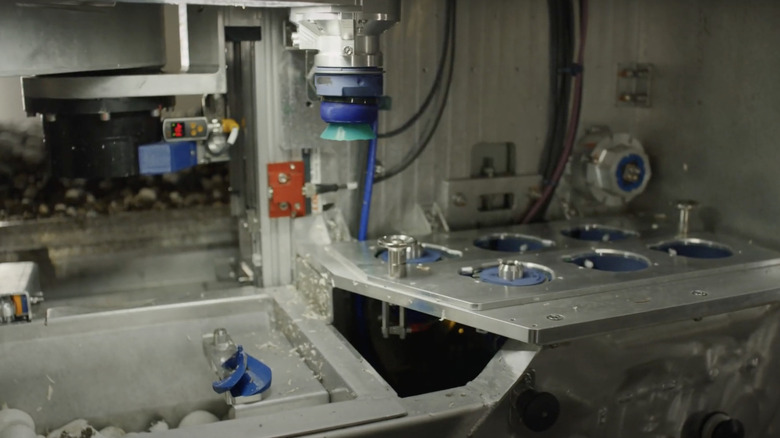

4AG's robots aim to fill that gap, with their robots having already been deployed in Canada, Ireland, and Australia. With their unique design, they can work in confined, dimly lit mushroom grow rooms while accurately scanning, selecting, and plucking with absolute precision. Unlike people, the bots don't tire, don't quit mid-season, and can run all night long if needed. For growers struggling to keep up with demand, that's game-changing.

The delicate art of robotic harvesting

Mushroom harvesting robots might seem like a small niche, although probably not as small as giant farming centipede robots, but it's an incredibly handy innovation for a finicky process. Mushrooms are fragile and need to be handled with care, then on top of that, they grow on tightly packed vertical shelves that are hard to navigate. This is where 4AG's technology steps in. Using specially designed computer vision and AI, the robots can identify mushrooms that are ready and avoid those needing extra growing time.

Rather than using brute force, the robots use slow, calculated movements and soft grippers to gently twist mushrooms from the growing beds without damaging them. It's a task that is usually undertaken by skilled human workers, but 4AG's system teaches itself through thousands of scans and real-time feedback. The result is a harvest that's faster, more consistent, and with less product loss.

Investors have clearly seen this potential. The global mushroom industry is projected to surpass $70 billion come 2030, and labor remains one of its greatest costs. 4AG has been praised by its investors for its tech-forward solution and the scalability of its systems, which look set to revolutionize the industry.

What this means for the future of farming

4AG Robotics isn't just building robots, it's building a blueprint for how automation can work in overlooked parts of agriculture. The company is now planning on expanding its production, bettering its AI's capacity, and expanding its network of robots across farms in North America after securing its new funding. They're not solely focused on robotics either, as they are also developing analytics tools to help growers plan their harvests better and reduce waste.

It's a more subtle innovation when compared to some of the most expensive tractors ever made or drone crop sprayers, but arguably just as important. That's exactly why this breakthrough matters, as Mushrooms aren't a staple crop, meaning there's more room to experiment and pioneer solutions. It's solving a niche problem with specialized tech and is a great example of what ag-tech will be capable of in the future.

If 4AG succeeds, it could open the door for robotics in other areas of farming that have resisted automation, although for good reason at times. It's proof that high-tech solutions don't have to be over the top and all-encompassing. Sometimes they just need to do a very specific job very well.