Why North Carolina Is Crucial To The Global Manufacture Of Chips And Processors

In September 2024, the state of North Carolina was wrecked by Hurricane Helene. According to the state government's estimates, over a hundred people lost their lives, and tens of thousands of homes were damaged. This wasn't just devastating to the locals, it also sent alarms blaring across the global semiconductor industry. The widespread flooding, communication snags, power outage, and infrastructure damage battered a small mining town called Spruce Pine, the location that supplies 80-90% of the world's quartz.

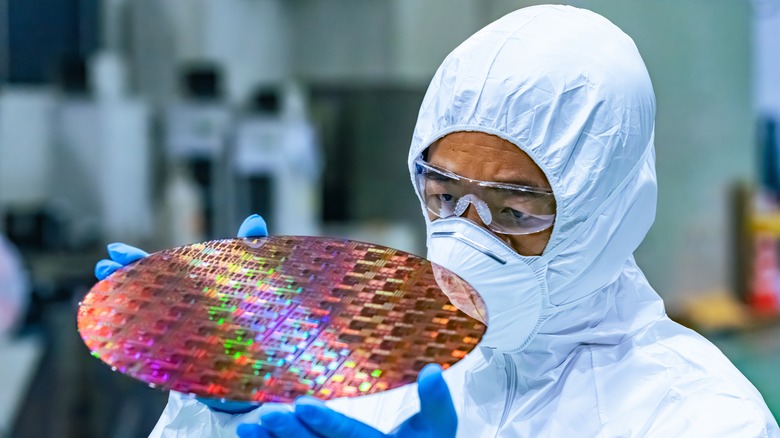

In fact, Spruce Pine is home to the purest quartz in the world. And you can't make semiconductors without silicon, a material that is extracted from quartz. Smartphones, computers, medical equipment, cars, industrial machines, and every other type of modern electronic system rely on semiconductors to operate. "Inside nearly every cell phone and computer chip you'll find quartz from Spruce Pine," Rolf Pippert, an executive at Quartz Corp, an established high-purity quartz supplier, told the BBC. In powdered form, silicon is melted and sliced into wafers, and then the circuits are printed on them. These circuits power the mobile, gaming, automotive, cryptocurrency, and AI industries. Winning the AI race is a top priority for the U.S. government, which has backed projects to make the country's AI infrastructure the largest in the world.

Why is North Carolina's quartz so valuable?

The general rule of thumb in the semiconductor industry is that the higher the purity, the better the product. That applies to everything, from the extremely controlled and sterilized chip printing process in labs to the material sourced for printing the wafers. The quartz sourced from Spruce Pine is held in high regard when it comes to purity. According to Sibelco, a global materials company that has been operating in the area since the 1970s, Spruce Pine is home to the world's highest quality quartz.

According to geologists, the quartz deposits formed around 380 million years ago, due to the intense heat and friction caused by tectonic shifts. "The purity of Spruce Pine's quartz is thanks to a lack of water where all the friction occurred, preventing the introduction of multiple impurities," says the company. The quartz, — technically referred to as high-purity quartz (HPQ) — is used to make semiconductor crucibles and silicon. Higher purity is desirable because it allows the wafer to survive the extremely high temperatures during processing.

But it's not just the purity of quartz mined from Spruce Pine that makes it special, but also the sheer quantity of it. "No other place on Earth has as much or as minable pure quartz as Spruce Pine," says a report published in The New York Times. Quartz Corp's Rolf Pippert told the BBC, "We have decades of material. The industry will probably change before we run out of quartz."

Why local quartz is the key to a global goal

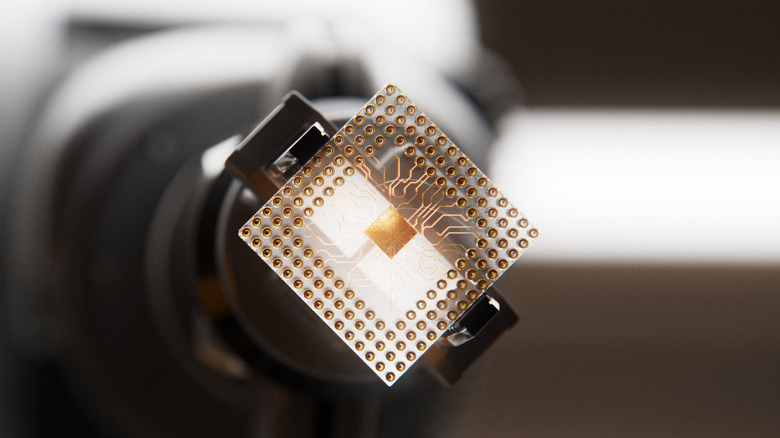

Quartz, after being extracted, is powdered into sand, which is then refined to obtain pure silica metal by melting it in a furnace and creating ingots. These are sliced into paper-thin wafers. The crucible where the process happens must be made out of pure quartz. "Only the highest quality quartz is acceptable for crucible manufacture to avoid contamination to the silicon melt," explains Quartz Corp.

The mechanism of separating silicon from oxygen is known as the Czochralski process, after the Polish scientist who invented the technique in 1916. Any impurity in the material disrupts the crystal structure and electrical properties, leading to defective chips. The concentration of metallic impurities must be less than one part per billion. The purity is important because contaminants can disrupt the controlled flow of electrons in the semiconductor, which would hinder the complex calculations performed by essential components, like the most powerful smartphone processors.

These exacting standards in purity underscore the critical role quartz plays in the global semiconductor supply chain. But none of it would be possible without the extremely pure raw material supplied by a tiny town in North Carolina. It's why the disruptions caused by Hurricane Helene made the entire global industry nervous. Previously, a fire incident in 2008 at a quartz refinery in the town made the market feel the heat. And as the AI race heats up, Spruce Pines' quartz will be a key card in the semiconductor game.