What Is Cavitation And How Does It Affect Ship Cruising Speed?

Cavitation is essentially a wild bit of physics that turns water — a ship's best friend — into a weapon with a massive destructive potential. It can happen around a ship's propeller and can eat through solid metal, kill its speed, and make a racket while doing it. To break down what it is, we'd first have to understand how a propeller works.

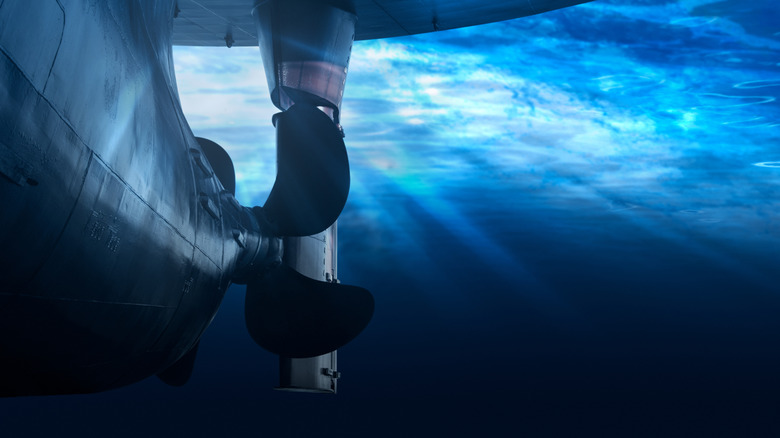

A propeller moves a ship forward by creating a powerful pressure difference in the water. Its rear-facing side generates high pressure that pushes water backward, while its front-facing side creates a low-pressure area of intense suction. The suction on the back accounts for about 80% of the total force. Here's where things get weird. If the propeller spins fast enough, the pressure on the suction side can drop so low that the water starts to boil, not from heat, but from the lack of pressure.

Water doesn't always need to hit 100°C to turn into vapor. At a low enough pressure, it can happen at much cooler temperatures. In case of a ship, water can evaporate at just 20°C when the pressure plummets. This process creates tiny vapor bubbles, which is pretty similar to the fizz you see when opening a soft drink bottle. These bubbles don't just float away. Instead, they get swept toward the edge of the blade into that higher-pressure area, where they collapse violently, creating an implosion. The force generates pressure surges of several hundred megapascals and localized temperatures that can reach a staggering 400°C. This is hot enough to temper the metal of the propeller itself.

How does it affect a ship's cruising speed?

First and foremost, cavitation affects a ship's performance. The layer of bubbles forming on the propeller blades effectively makes them "thicker", which increases resistance. This leads directly to a loss of speed because the propeller can no longer generate its intended thrust. As the cavitation gets worse, you'll see a marked increase in engine RPMs for a given power output, signaling a serious drop in efficiency.

Then there's the physical damage, which is brutal. The constant, high-energy collapse of bubbles acts like a microscopic hammer and batters the blade surface. Material gets eroded, leading to the blade leaving a sponge-like texture. In the initial stages, the surface gets a tell-tale "orange peel effect". But in extreme cases, cavitation can chew a hole straight through a solid metal blade.

Beyond speed and damage, cavitation creates a ton of vibration and noise. All that bubbling leads to high vibrations that can damage expensive parts like bearings and seals. As for the noise, an article from the International Institute of Marine Surveying vividly describes it as "gravel being forcibly thrown against the underside of the hull".

How to prevent cavitation

Of course, engineers have several tricks up their sleeves to fight cavitation. A key strategy is to use propellers with a larger blade area or wider blades, which helps spread the thrust load more evenly. Flat, low-loaded blade profiles are also often used for ships that travel slower than 35 knots to keep pressure differences in check. This is valid for container ships, which typically maintain 24 knots in speed, and the largest oil tankers. Another important factor is the choice of material. Bronze alloys and stainless steel are commonly used for their durability. Even the ship's stern can be shaped to create a more uniform water flow into the propeller.

Interestingly, some engineers decided that if you can't beat 'em, join 'em. This led to the concept of supercavitation, where cavitation is intentionally made so intense that it creates one giant, stable vapor bubble that envelops the entire object. This bubble drastically reduces friction drag and allows for incredible speeds. It's tricky to pull off, though, which is why it's more commonly seen in experimental ships like the General Dynamics GHOST Small Unmanned Vessel.