Why Does The Duramax Diesel Engine Have Two Thermostats?

For diesel engines to work their best, precision is everything. That's why, unlike traditional gasoline-powered engines, a Duramax diesel engine has two thermostats. After all, there are some seriously intense demands placed on diesel engines, and that includes the diesel's cooling system.

Duramax's dual-thermostat setup isn't a case of over-engineering or some accidental redundancy. It's a deliberate design choice that's meant to give you even more precise temperature control, no matter if you're cruising empty down the highway or hauling a trailer up a mountain pass. The use of dual thermostats helps the engine better regulate heat across a wide range of workloads, better protecting the engine from damage and ultimately improving its overall performance.

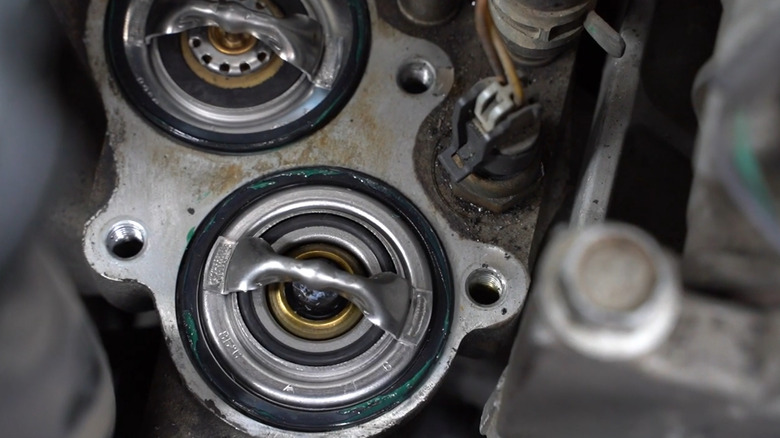

Simply speaking, the point of a thermostat is the same in any internal combustion engine: It's there to regulate coolant flow, which helps the engine reach and maintain its optimal operating temperature. In most of the legendary Duramax diesel engines, this process is more complex. The system uses a rear, or primary thermostat, and a front, or secondary thermostat, each with its own responsibilities.

What do the thermostats do on a Duramax diesel engine?

A Duramax diesel engine's primary thermostat uses a non-blocking, two-stage design that starts to open at 82°C (180°F). This allows a small amount of coolant to begin circulating through the radiator. As the engine temperature climbs, the second stage opens at 85 degrees Celsius, or 185 degrees Fahrenheit, increasing the coolant flow. It's not fully open until 95 degrees Celsius, or 203 celsius Fahrenheit. This lets the coolant flow gradually ramp up to match the increasing heat of the engine rather than flooding the radiator all at once.

What really makes the most reliable Duramax engines different is the inclusion of the secondary thermostat. This one features a single-stage design and a bypass flapper valve for managing the circulation of coolant while the engine is still warming up. Like the second stage of the primary thermostat, it also begins opening at 85 degrees Celsius or 185 Fahrenheit. As this second thermostat opens, it simultaneously starts to close off the internal bypass passage. This dual action helps make sure the coolant is routed efficiently through the radiator only when it's truly needed.

When the primary thermostat reaches full open status, the bypass flow is completely shut off. In turn, this maximizes the engine's access to external cooling. In other words, both thermostats coordinate to fine tune coolant flow based on precise temperature triggers, helping to maintain engine temperature within a tight and reliable range.

Why would you need two thermostats?

It's easy to dismiss the dual-thermostat setup in cars with a Duramax diesel engine under the hood, especially when some truck drivers might only ever use the primary thermostat most of the time. It's true: During light-duty operation, such as daily driving without a trailer, the first thermostat may be enough to let the engine warm up quickly.

When the truck is under heavy load, like towing, climbing steep grades, or driving in high outside temperatures, engine temperatures can spike rapidly. That's when the second thermostat kicks in, effectively opening up the rest of the cooling system to provide extra capacity. This adaptability is an absolute must-have for diesel engines, especially considering how they operate under higher compression and generate more heat than their gasoline counterparts.

Beyond simple performance, the dual thermostat design also helps with engine longevity. Prolonged periods of overheating can lead to warped cylinder heads, cracked blocks, or blown gaskets – all of which would result in catastrophic engine failures. With dual thermostats working together, temperature regulation becomes more responsive, and not to mention, more reliable. This, logically, reduces the likelihood of overheating, and the issues that come with it.