What Are The Belts On Military Tanks Called And How Do They Work?

Tanks are an essential element among military forces worldwide because they provide a strong, mobile, and armored platform for offensive and defensive operations. Among the many advantages are strong mobile firepower and armor that allows them to engage enemy armored vehicles, fortifications, and infantry positions. In addition, one of the tank's most important characteristics is its mobility, which enables rapid advances or responses, such as attacking enemy defenses and giving infantry support. Despite its size and weight, a tank can easily move around the battlefield because of its unique propulsion design, which uses belts or treads instead of wheels.

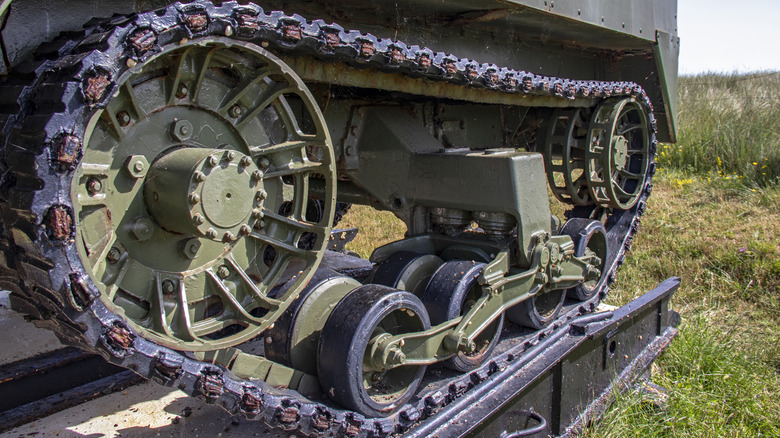

One of the most important parts of a tank is its treads, also known as caterpillar tracks. The system works by having the tank treads connected to several sprockets, which roll the road wheels, similar to a continuous chain drive that provides traction for the vehicle. To move the tank, its engine power spins the sprockets, which in turn move the treads. To keep the treads from slipping off, the track is attached to rollers and tensioners that use hydraulics or springs that maintain the correct tension.

To bear the weight of the tank, the treads are made of interconnected steel and manganese steel plates, held together by long metal pins. In addition, the treads also have rubber pads that improve traction and agility, maintain grip on surfaces, and reduce damage to paved roadways. Additionally, they can minimize noise and vibration, which enhances overall ride quality. Tracks have always been used on tanks, including on the Little Willie, which was the world's very first working tank. Throughout history, a majority of tanks, including the most powerful versions, called battle tanks, have continued to have the caterpillar tracks as an integral part of their design.

Combat ready all terrain propulsion

Because tank treads can support much heavier weight and provide better all-terrain mobility, they perform better than wheeled vehicles in several aspects. Due to their ability to distribute weight over a wider area, the treads lessen ground pressure and keep vehicles from sinking or becoming stuck in mud, sand, or snow. Another important advantage of treads is their durability. They are made of tough steel alloys, which last longer than rubber tires, and are not vulnerable to punctures and deflation. This minimizes maintenance and reduces replacement costs.

There are, however, several disadvantages to using tank treads. Starting with speed, using treads on vehicles makes them slower compared to wheeled vehicles, which makes them vulnerable to attack. Next, their more complex systems require more time to repair. If the tread comes off the tank, it is rendered immobile and may need to be towed unless the tank crew can fix it. Lastly, metal tank treads can damage road surfaces and are noisier compared to rubber wheels.

Due to their exceptional mobility, firepower, and protection, though, tanks will continue to play a vital role in military arsenals and land combat in the future. Technology has driven innovation in tanks, and several notable examples have impacted their use, influencing battlefield tactics and tank design even today. To ensure their continued relevance on the contemporary battlefield, tanks are evolving in response to new threats, with developments that could make their way to the next generation of tanks, including enhanced armor, integration of artificial intelligence, and, propulsion modifications developed by the Defense Advanced Research Projects Agency (DARPA) that involve a hybrid between treads and wheels called the transforming wheel track.