CNC Vs. Laser: What Are The Pros & Cons Of Each For Woodworking?

There are a lot of different kinds of power tools out there for woodworkers who want to amplify their skills (either professionally or as a hobby). Unfortunately, choosing the right one (especially when it comes to woodworking projects, like engraving, that require precision) can be challenging. That's because each tool has a specific kind of cutting and engraving task that it's best suited for. After all, what works best for creating complex 3D contours might not be the best for precise surface etching. This brings us to two of the most debated tools in this space — CNC routers and laser cutters.

At a glance, these two tools might look like they belong to the same toolbox. Both use digital designs to automate even the most complex patterns. Plus, they can both cut, shape, or engrave wood into impressive art pieces. But that's where their similarities end. Once you look at how they do it — and the results they deliver — their differences start to matter. CNC routers, for instance, usually use spin bits to carve through a material. This makes them ideal for sculpting complex 3D contours and ploughing through thick hardwood stock. Laser cutters, on the other hand, usually use beams of light to burn a surface. This makes them ideal for creating personalized artworks and 3D puzzles. This is what each tool does best and what you'll want to use them for.

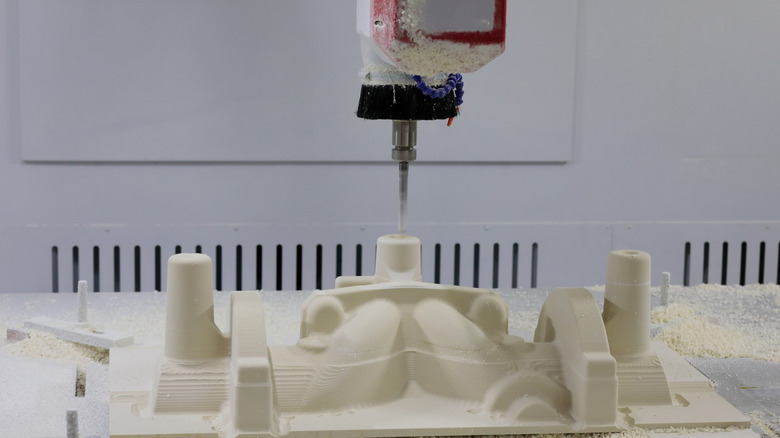

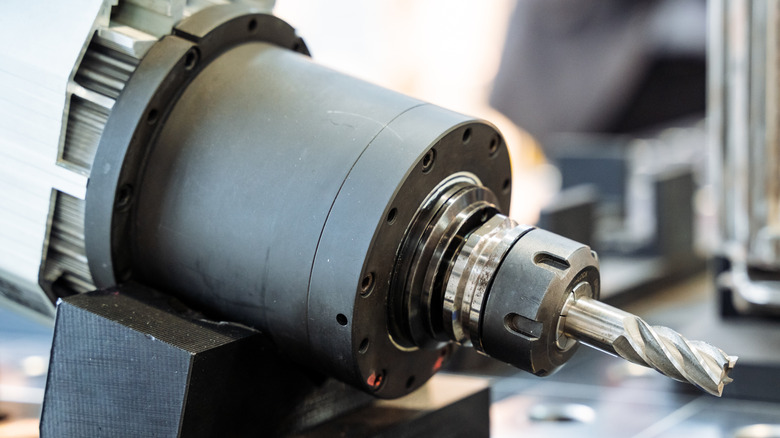

Why CNC routers are a powerhouse tool for woodworkers

If you are serious about woodworking, a CNC router is an essential workshop tool that can undoubtedly boost your production schedules and skills. The reason is that it's versatile and quite valuable for just about every woodworking project. You can use a CNC router to create wall art with intricate designs or even precisely cut thick materials that would take hours to complete. Since this tool uses router bits to carve through a material, it can be quite flexible in making precise cuts on traditional hardwoods and softwoods, plastics, composite materials (including MDF and plywood), and softer metals like aluminum.

Apart from versatility and flexibility, another standout benefit is depth control. In fact, there is a reason why the CNC router is great for creating precise 2D and 3D cuts and engravings. Unlike laser cutters that usually burn through the surface, routers usually use bits to create complex 2D and 3D cuts without compromising accuracy. Plus, they always follow a programmed path to deliver consistent results, whether you're cutting joinery, carving a decorative bowl, or engraving custom logos.

While it's true that the upfront cost of this machine can be quite high, the machine will last a long time with proper maintenance. Plus, it requires less maintenance, given that you'll only have to replace the bits once they wear down. Lastly, they're better suited for batch production. Once programmed, you can replicate the same design over and over again without starting from scratch — saving both material and time. Since there's no reliance on high heat, you'll avoid discoloration and scorching, problems that are quite common with laser cutters.

Why CNC routers might not be the right fit for every woodworker

CNC routers offer unmatched precision and versatility, but that's not to say they're perfect for everyone. In fact, for some workshops, they may introduce more problems than solutions. For one, a CNC router can be quite expensive. While there are budget versions of just about every tool, the sad truth is that even the decent entry-level of this machine can set you back a few hundred dollars. That's even before you factor in the cost of the software and tooling.

There is also the issue of the learning curve. At first, you might assume that operating a CNC router is as simple as turning on a table saw. But that's not the case. In fact, to use these high-tech tools, you'll have to learn CAM/CAD software. You'll also have to learn how to properly set up your materials, as mistakes (even minor) could result in wasted wood or machine damage.

Another major drawback is the noise and mess that CNC routers create. All that cutting and carving will generate a lot of sawdust and woodchips, making your workspace look messy. Additionally, the whirring spindle and the vacuum system of the CNC routers are often loud during operation. This might not be a significant issue in an industrial setting, but in home workshops (or spaces in residential areas), the sound can be noticeably disruptive.

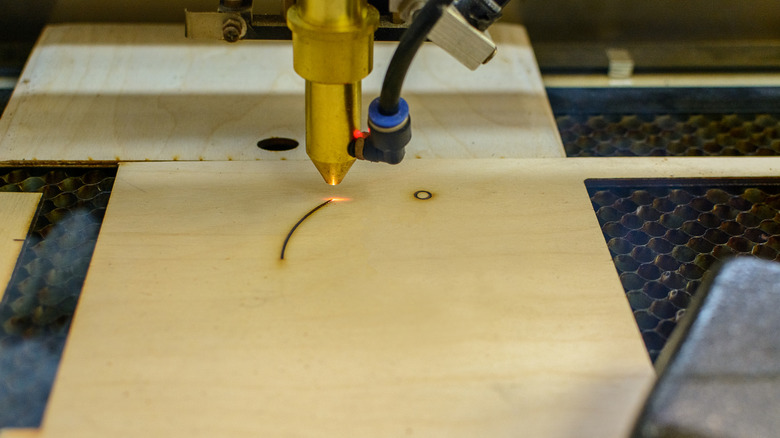

Why laser cutters are a smart choice for precision woodworking

When a woodworking project calls for precision, fine engravings, and meticulous details, laser cutters are hard to beat. After all, these machines use a focused light beam to etch, engrave, or cut wood (all while maintaining a tolerance that is as tight as ± 0.1 mm). This makes them ideal for ornate pieces, custom signage, intricate inlays, and detailed artwork. This also brings about material efficiency, as the kerf (the material removed during cutting) after laser cutting is often barely noticeable, sometimes as low as 0.1 mm.

Of course, one of the most satisfying aspects of laser cutting is the smooth edges it produces. The concentrated beam of light seals and polishes the cut as it goes, leaving your pieces with a ready-to-use, professional finish. This might seem like a small benefit, but when you're working on projects where presentation matters (say, display pieces, fine furniture components, or retail products), you'll definitely save a lot of time post-processing. Additionally, since the process involves minimal physical contact with materials — no blade drags the wood — there's reduced risk of chipping or warping delicate pieces, especially veneers.

The drawbacks of using laser cutters in a woodworking setup

While laser cutters have gained popularity over the years because of their clean finishes, they also come with trade-offs that you should consider before committing to one. For starters, the cutting speed can slow down significantly when tackling a woodworking project. Unlike CNC routers that will handle dense materials without a fuse, the cutting depth and effectiveness of laser cutters (even high-tech models like the XTool P2) will fall short once you start working on thicker boards. So, if you plan to build structural furniture pieces, it's best that you consider CNC routers or plasma cutters, which might offer a better solution.

Price is also another drawback. While entry-level models might seem affordable (with some ranging between $2000 and $3,000), that price might be a significant barrier for beginners who want to learn woodworking. Also, these affordable models might lack the power to handle serious projects. Apart from that concern, edge quality is another issue. This power tool is known for its unmatched precision, but the cutting method relies on much heat that can char and burn the edges of your material. Not only will this bring a cosmetic problem to the finished product, but it will also affect how well pieces fit together.