Audi Is Using AI Where You Least Expect It (And The Benefits Could Be Huge)

The automotive industry has been at the forefront of the artificial intelligence boom, with high-profile innovations like self-driving cars and AI-powered driver-assist features frequently coming to the forefront of consumers' minds when considering how machine learning is shaping everything around us. But Audi is doing more than using AI in next-gen vehicles; it's also changing how its cars are made in the first place.

Manufacturers are facing a difficult balancing act as they incorporate artificial intelligence into production lines, amid concerns over the collateral damage of these processes. While these doubts aren't unique to AI, the technology's rapid development increases the pressure of these questions, requiring manufacturers to answer them as quickly as they develop the technology itself.

Audi, for its part, appears to be employing a human-centric approach that changes how the German company views its manufacturing processes. According to an interview with Rüdiger Eck and Stefan Keckl, two of the company's AI experts at the program's outset in 2021, Audi views AI as a supportive tool best situated for areas where humans may not be set up to succeed, such as "analyzing large amounts of data or repetitive work." This results in observers being able to categorize Audi's AI usage in two broad categories: quality assurance and data utilization. According to the company, Audi has over 100 AI projects under development, which it hopes will increase the efficiency of its production lines by 30%.

Quality Assurance

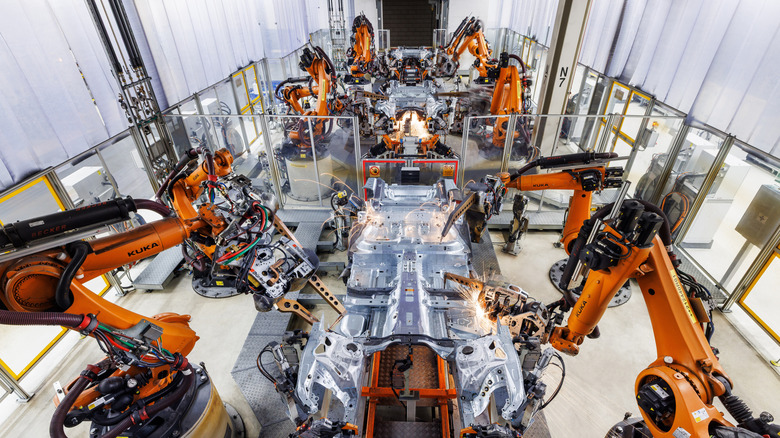

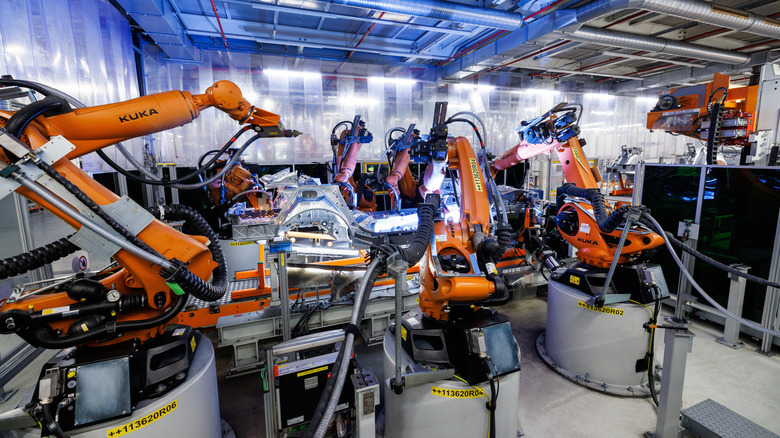

The most straightforward application of artificial intelligence in Audi's production lines is its use as a quality assurance tool. According to Eck and Keckl, AI is uniquely suited for work centered around highly repetitive tasks, allowing employees to focus on the work that requires "a complex mixture of cognitive performance, physical movement, and sensory perception."

One such example is one of Audi's first AI applications, the Weld Splatter Detection system, which program analyzes data from Audi's welding machines to determine the quality of each spot weld. With its partner Siemens, Audi can detect when molten bubbles form along the underside of the vehicle, which can cause damaged cables and wires or long-term corrosion. The system has been incredibly successful, and a 2023 press release touts that the tool can analyze 1.5 million spot welds on 300 vehicles in a single shift. Workers previously relied on ultrasounds to randomly inspect selected welds on vehicles. For reference, your average Audi A6 is connected by roughly 5,300 spot welds.

A similar example is the use of AI in Audi's Ingolstadt factory to review the quality of pressed parts. Before its rollout in 2018, workers again used ultrasounds to randomly inspect part presses. A June 2024 study shows that AI-powered improvements could provide major efficiency benefits for Audi's factories, as roughly one in every 1,000 of a factory's 3.1 million yearly pressed parts is cracked. Just as illustrative is Audi's IRIS system, in which AI-powered cameras determine if technical labels are correctly applied to each vehicle.

Sifting through the 'data swamp'

The real boon for Audi's AI program is its ability to collect, store, and analyze data. Think of the factories as living information systems churning out reams of data by the second. Audi's factories produce thousands of gigabytes of data every day, which learning models can collect and harness at scale for the first time. From there, the learning models can recognize inefficiencies and project issue areas, converting previously static operations into flexible, adaptable processes. Every step of production, from procurement tenders to individual machines on its assembly lines, is now a potential data point waiting to inform future decisions.

For example, Audi's 'Tender Toucan' tool, set to debut in summer 2025, filters supplier bids for parts like drivetrains and high-volt batteries according to a preset list of requirements, reducing the time employees spend evaluating tenders by roughly 30%. The Toucan system exemplifies what Eck and Keckl laid out in their 2021 vision: an AI-powered system that augments human-driven processes. Other examples include forecasting equipment failures, reducing logistical inefficiencies, and simulating new production rollouts. As a whole, the company predicts that such systems will significantly cut its production time, with select programs reducing machine downtime and employee workloads by 30 percent.

A difficult balance

This is not to say that Audi's use of artificial intelligence is without risk. Much has been said in recent years about AI's effect on global job markets. A 2025 Future of Jobs Report by the World Economic Forum showed that 41% of employers intend to reduce their workforce in favor of AI, while Goldman Sachs estimated that generative AI could automate half of the U.S. job market by 2045. These worries are particularly poignant for factory workers; a 2025 Pew Research survey showed that experts believe AI will greatly impact the industry's job opportunities. These projections are less catastrophic than the doomsday forecast of the previous decade, when McKinsey and Company predicted AI could automate up to 70% of work activities and displace 800 million workers by 2030, but they reflect mounting concerns in a manufacturing sector hit by serious layoffs in 2025.

This is particularly true in the automotive industry. An influx of pressure from tariffs, slumping demand, and changing market conditions prompted layoffs at companies like Ford, Tesla, and Stellantis. In March 2025, Honda Motor announced that it had cut 30% of its Guangzhou EV plant's workforce due to redundancies with its AI systems. That same month, Audi announced an 8% cut of its workforce by 2029. While these cuts are not expressly caused by AI programs, Audi stated that a portion of its one billion euros in savings would be invested in the technology. More importantly, the dual tracts reflect a broader trend in which AI-powered factory automation coalesces with industry-wide job cuts. As such, it poses difficult questions for Audi as it looks to balance technological progress with reducing the human collateral that such innovations may incur.