What Does A Kerf Cut Mean In Woodworking?

It seems like just about every hobby under the sun requires its practitioners to learn an entire vocabulary of specialized terms, whether it's music, cooking, or woodworking. Sometimes people who have been dabbling in carpentry since middle school shop class forget that not everyone knows all of these terms, and so it's not uncommon for building plans and how-to guides to use them without explanation as to what they mean.

"Kerf" is a term that every woodworker will probably come across as soon as they start doing small, beginner-friendly woodworking projects, though it can be a bit tricky to explain as it sort of has three different meanings. A kerf may refer to the width of a saw blade (the blade's kerf), it may refer to the width of the material removed by the saw in a cut (which is roughly the same as the width of the blade), or it may refer to a specific technique that involves making one or more shallow cuts that create a channel in the wood the width of the blade, but which doesn't pass all the way through the material. Understanding the kerf of a saw is vitally important for cutting wood accurately, but it can also be used in several woodworking techniques.

It's important to account for the kerf when cutting

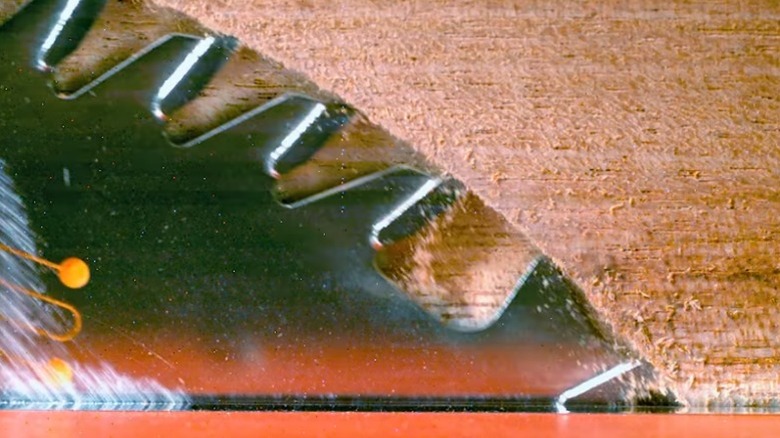

Unlike a knife blade, which splits material along its edge, the teeth on circular saws, miter saws, and table saws work more like tiny shovels. They scoop out pieces of wood along alternating angled blades on the edges of the teeth. This usually removes about ~⅛-inch of material with each cut, but the exact width can vary depending on the blade. Even saws with angled flat metal teeth, like those found in a jigsaw, reciprocating saw, or band saw, will remove a small amount of material with every cut. These blades typically make a much thinner kerf, but it's still something that you'll want to be aware of.

It's important to account for the kerf of a cut for a few different reasons. The first is that you need to line up your cuts so that the entire kerf of the blade is on the outside of the marked length of the piece you're attempting to cut. If the blade passes through the center of the marked line, you will inadvertently make the piece a fraction of an inch shorter than you wanted, as part of the blade removes material from the measured length. This might not be a big deal when cutting 2x4s for a construction project where "close enough" is functionally acceptable, but it's vitally important in fine woodworking projects where you're seeking to have pieces fit perfectly together.

It's also important to note the amount of material lost with each cut when you're measuring out the amount of lumber you need. You can't, for instance, get four 2-foot lengths from a single 8-foot board. The kerf removes material with each cut, so the last of them would be ~⅜-inches shorter than the other three.

Kerf cuts can be used in several woodworking techniques

Accounting for the kerf of a saw blade is important for getting accurately measured cuts, but there are also a few ways that you can use it to your advantage, especially if you have a quality table saw. By lowering the height of the blade until it won't pass fully through the wood, you can cut channels into the surface of a board. You can make multiple parallel passes to make the channel wider, or you can use specialized dado blades to thicken the kerf and make cleaner cutouts. I've personally used this technique to create channels for hiding LED strip lights in the underside of bookshelves, to make channels for glass in a picture frame, and even for making a piece of plywood look like it was made of planks while building a prop Viking shield by cutting decorative channels.

You can also make multiple closely spaced kerf cuts across the grain of a board in order to achieve an effect called "kerf bending." These kerf cuts create space on one side of the board, loosening its rigidity and allowing you to bend it into an arch. Filling the space inside the kerfs with a strong wood glue binds them together while the board sets into this final shape. Similar to this, some woodworkers have also made kerf cuts on the underside of large slabs that have started to warp or bow in order to serve as a relief point and correct them when planning them flat isn't an option.