GDI Vs PFI Engines: What's The Difference?

Everybody realizes the importance of an engine, but something that's equally crucial, if not more, is the fuel delivery. Only the right mixture of fuel and air can ensure efficient performance with lower emissions — something that's become more relevant than ever with car manufacturers going green. Invented in the late 1880s by Karl Benz, the carburetor brought significant advancements to the automotive industry and was a reliable device widely used until the introduction of the more precise fuel injection system.

There are both pros and cons of fuel injection technology and carburetors. Despite the world of automotive shifting towards fuel injector engines, we still see carburetors in smaller vehicles like scooters, or in appliances like lawn mowers. The debate doesn't end there, since there are various kinds of fuel injection systems in modern cars and motorcycles. The most popular ones include PFI and GDI. But how exactly do these systems differ from one another, and which one would yield more benefits?

The fundamental difference between PFI and GDI engines

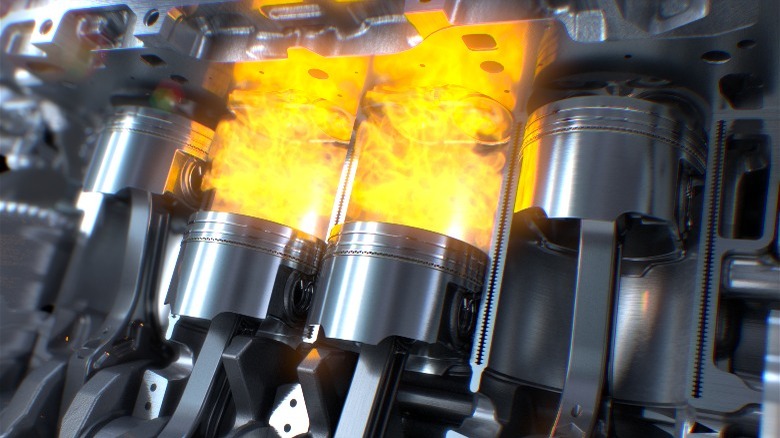

Fuel injection was one of the most important discoveries in the automotive space, and follows the concept of introducing fuel into the combustion chamber of an engine through an electronically controlled valve. Modern-day vehicles are quite smart, and have microcomputers that dictate when and how much fuel is delivered to the engine, depending on the driving conditions at that given point in time.

PFI, or Port Fuel Injection, was introduced in the late 1980s and offered more precise control over the air to fuel mixture. In this design, the injector is located in such a manner that the fuel is sprayed into the intake valve of the engine. Here, the fuel mixes with air before being directed into the combustion chamber.

GDI, or Gasoline Direct Injection, on the other hand, applies a slightly different approach to the fuel injection process. Instead of spraying it in the intake manifolds, the fuel injector is located close to the spark plug, allowing the fuel to be injected directly into the combustion chamber, where it then mixes with the air that's let in through the valve.

Advantages and downsides of both the systems

GDI's most obvious benefit over PFI is efficiency. Since the fuel doesn't have to pass through the intake ports, there is overall less mechanical energy required to pump the air. GDI engines are also able to leverage significantly higher pressures of fuel being injected in the chamber. This means a GDI engine often outputs higher power with the same amount of fuel compared to a PFI engine, promoting better efficiency.

While this improvement has made Gasoline Direct Injection systems an edge in today's automotive world, it doesn't come without a few sacrifices. First, GDI engines require comparatively complex engineering and may warrant higher costs for repairs. Unlike PFI engines, where the fuel acts as a cleaning agent inside the intake ports, GDI is more prone to carbon build-up, and ends up producing more soot. GDI engines also require higher pressures and hotter temperatures to operate.

Still, with the ability to be controlled more precisely, GDI engines have increased fuel efficiency while producing higher power outputs. Both these fuel injection technologies are used by some of the best car engines that are in production today, and continue to drive innovations by offering better performance and efficiency.